Semiconductor device welding mechanism

A welding mechanism and semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems that affect the welding effect of semiconductor devices, easily destroy the surface of semiconductor devices, and the heating surface is not uniform enough, so as to eliminate heating Uneven surface, ensuring heating uniformity, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

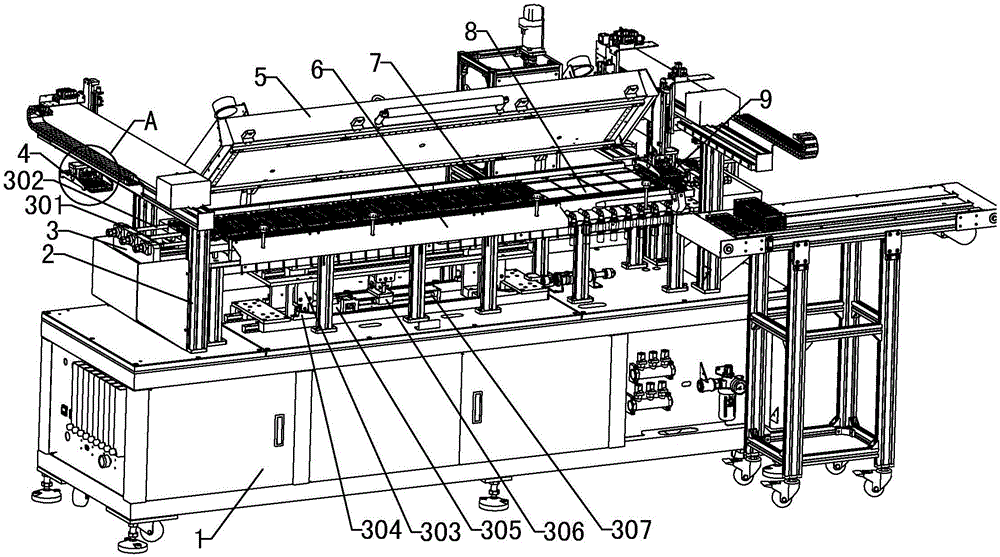

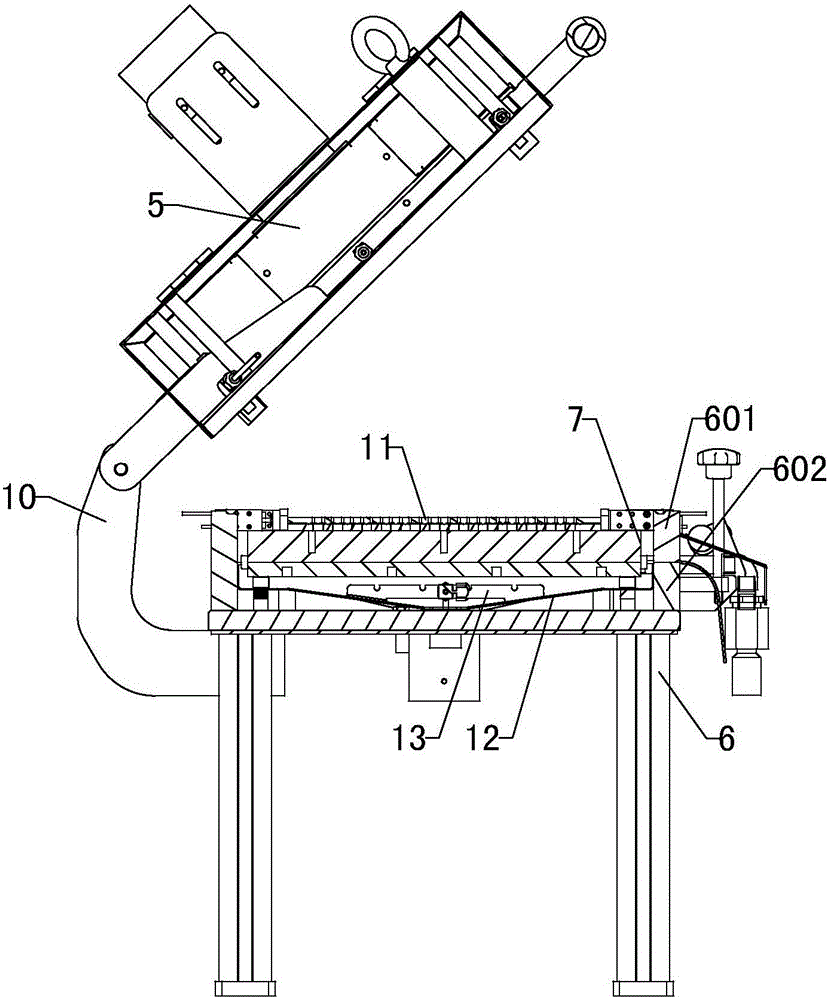

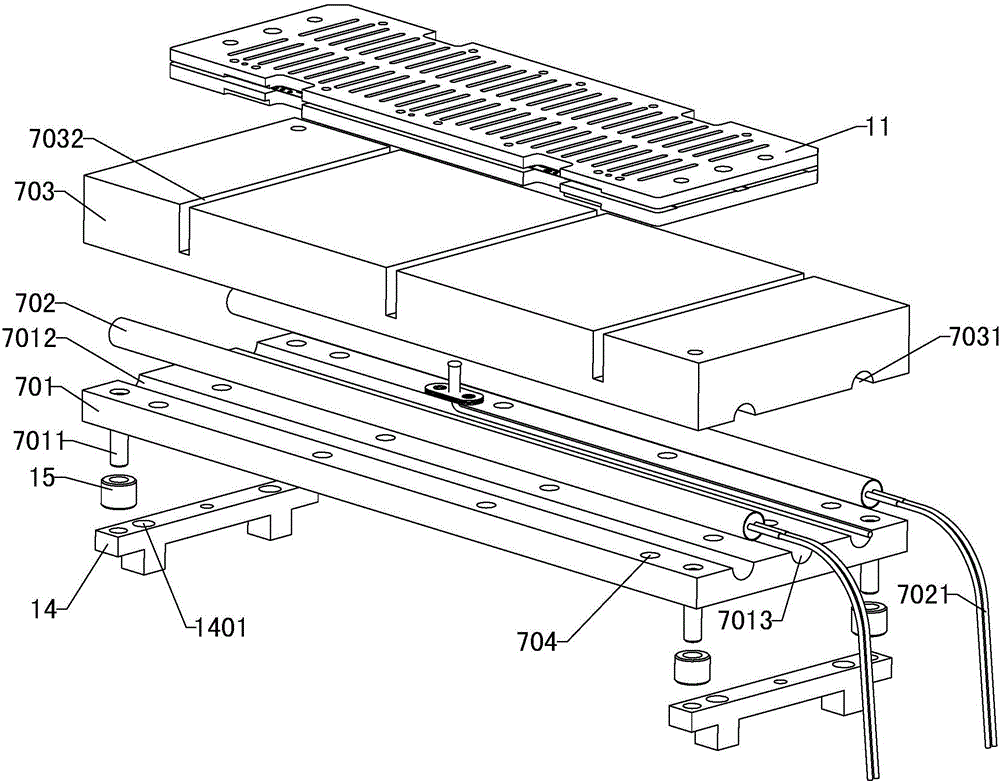

[0025] Figure 1~5 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~5 The present invention will be further described.

[0026] Refer to attached Figure 1~5 : a semiconductor device welding mechanism, comprising a frame 6, a heating mechanism 7 is provided on the frame 6, and the heating mechanism 7 includes a plurality of heating plates laid side by side on the frame 6; the frame 6 is also provided with a transport semiconductor device The lifting and moving mechanism 3 displaced in the horizontal direction, the lifting and moving mechanism 3 lifts the conductor device 11 from one heating plate and simultaneously drives the semiconductor device 11 to move horizontally to the next heating plate.

[0027] A semiconductor device 11 is separately placed on the top surface of each heating plate. Preferably, the lifting and moving mechanism 3 is arranged below the heating mechanism 7, and the moving end of the lifting and moving me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com