Dual-glass photovoltaic module

A double-glass photovoltaic and module technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of uneven inner edges of hot melt adhesives, affecting the appearance of components, and poor appearance, so as to improve photovoltaic characteristics and improve absorption performance. , Reasonable design effect

Inactive Publication Date: 2017-05-10

ANHUI ELECTRIC GRP SHARES

View PDF4 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to improve the insulation and water resistance performance of the double-glass photovoltaic module, a certain width of hot melt adhesive can be coated around the photovoltaic module, and the coating of hot melt adhesive requires special equipment to be heated, and it is easy to cause dirt during the coating process. Contamination and other problems, low process feasibility: At the same time, after the coating is completed, the hot melt adhesive will flow unevenly during the lamination process, resulting in uneven inner edges of the hot melt adhesive and poor appearance, which will affect the appearance of the entire component

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 3

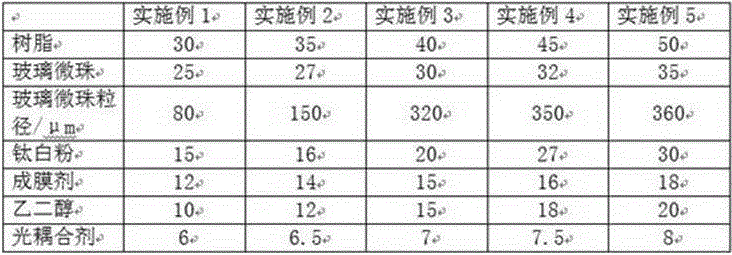

[0029] Embodiment 3 is a preferred implementation.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical field of a photovoltaic material, particularly to a dual-glass photovoltaic module. A packaging layer is arranged on the edges of a first glass layer and a second glass layer; an upper hot melting adhesive layer is arranged between the first glass layer and a first adhesive film layer; a lower hot melting adhesive layer is arranged between a second adhesive film layer and the second glass layer; one side, towards a battery piece, of the second glass layer is coated with a reflective coating layer, wherein the reflective coating layer is white organic polymer coating layer; and the reflective coating layer adopts a flat panel network-shaped. The dual-glass photovoltaic module disclosed by the invention is simple in structure and reasonable in design; and meanwhile, the structure of the dual-glass module is improved from the two aspects of increasing sunlight projection rate and preventing sunlight emission, so that the sunlight absorption performance of the dual-glass module is improved fundamentally, and the photovoltaic characteristic of the dual-glass module is improved.

Description

technical field [0001] The invention relates to the technical field of photovoltaic materials, in particular to a double-glass photovoltaic module. Background technique [0002] With the continuous development of photovoltaic technology, photovoltaic modules have been widely used in many industries such as construction engineering. Double-glass photovoltaic modules are a relatively common photovoltaic module. people's attention. [0003] In order to improve the insulation and water resistance performance of the double-glass photovoltaic module, a certain width of hot melt adhesive can be coated around the photovoltaic module, and the coating of hot melt adhesive requires special equipment to be heated, and it is easy to cause dirt during the coating process. Pollution and other problems, low process feasibility: At the same time, after the coating is completed, the hot melt adhesive will flow unevenly during the lamination process, resulting in uneven inner edges of the hot...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01L31/048H01L31/054

CPCY02E10/52H01L31/0488H01L31/0547

Inventor 童茜

Owner ANHUI ELECTRIC GRP SHARES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com