Encapsulation method of thin cable with braided structure for space solar cell array

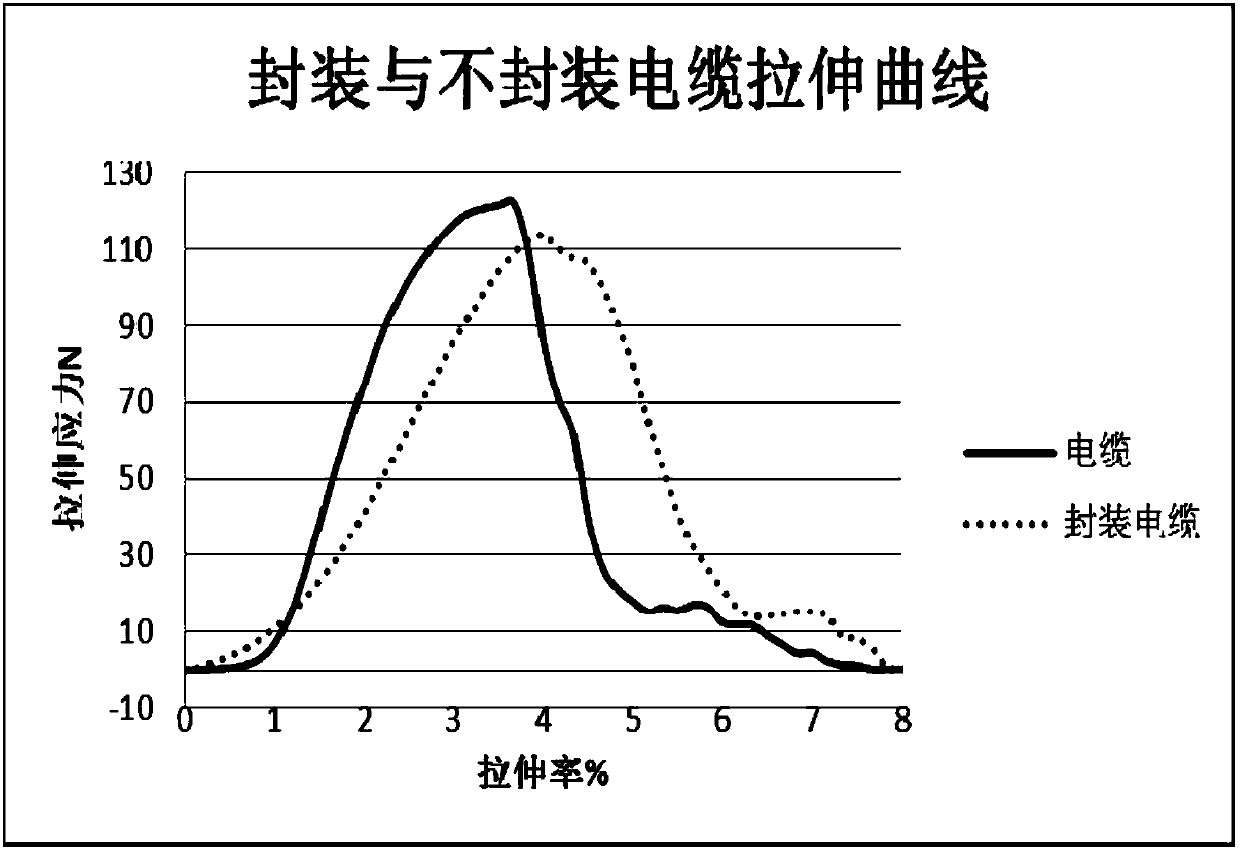

A solar cell array and solar cell technology, applied in the field of space solar cell array power transmission, can solve the problems that the installation size cannot meet the needs of flexible solar cell arrays, and the circular cross-section wires do not have structural elongation, etc., to achieve good Space environment adaptability, elimination of potential safety hazards, effects of preventing electrostatic discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

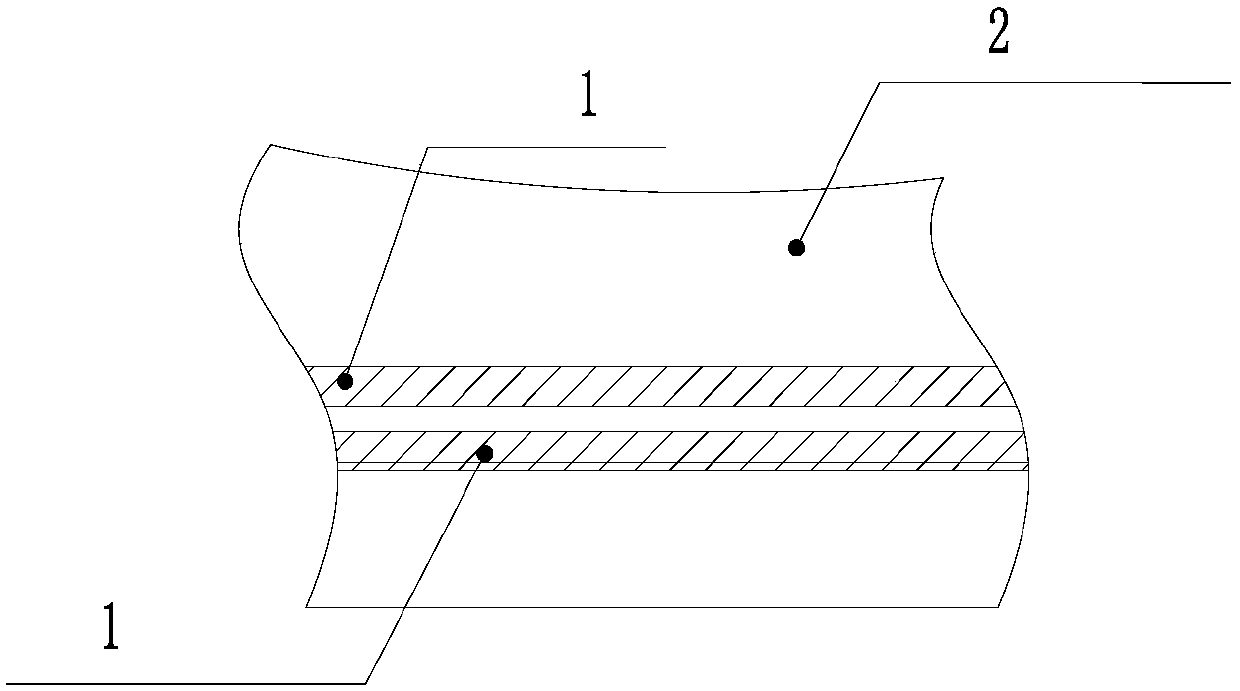

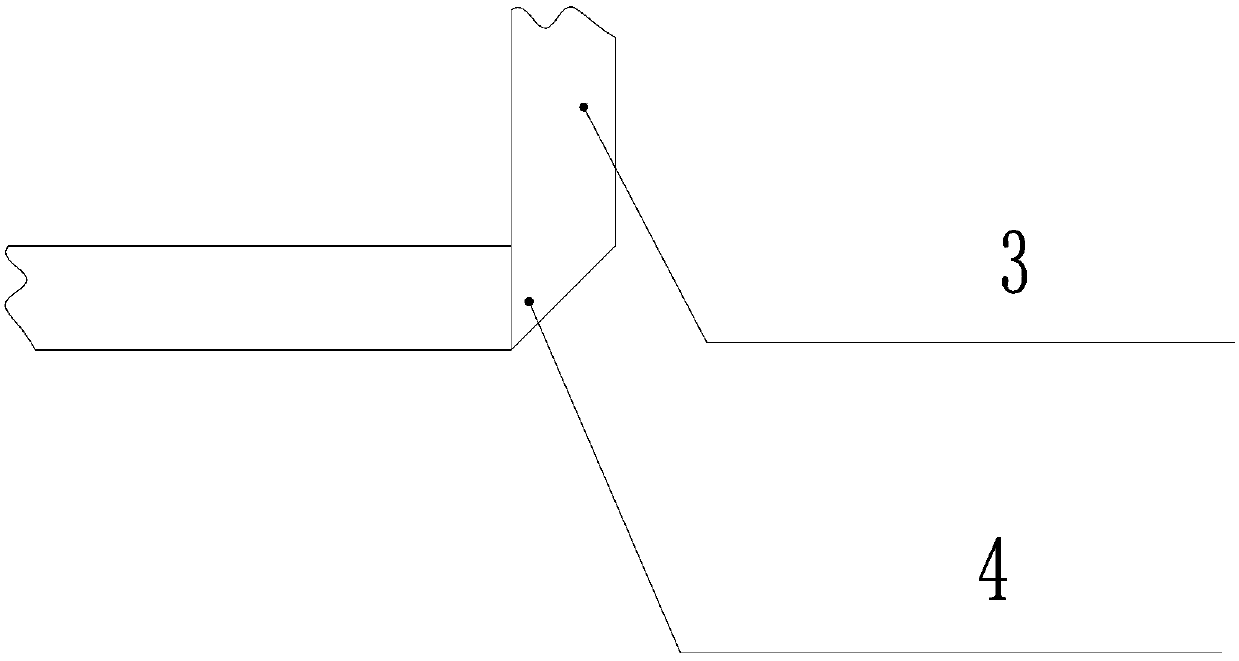

[0030] see Figure 1 to Figure 3 A method for encapsulating a braided structure thin cable for a space solar cell array, comprising the steps of:

[0031] 1. Installation location positioning

[0032] Place the solar cell array substrate 2 stably, place the positioning mold on the substrate in the forward direction according to the text, and fix the positioning mold with positioning pins through the four corner positioning holes and the operating platform. According to the pattern of the workbench positioning mold, use glue / 1 to enclose the position to be glued on the substrate of the braided flat cable 3 (see attached figure 2 ).

[0033] 2. Surface treatment of packaging position

[0034] Place the cable leakage film on the board on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com