Fuel cell thermal management system with heat accumulation and heating functions and control method

A thermal management system and fuel cell technology, applied in fuel cell control, fuel cells, fuel cell additives, etc., can solve the problems of rough control, failure of ion exchanger, low energy utilization rate, etc., to avoid impact and reduce power consumption. The effect of high consumption and control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

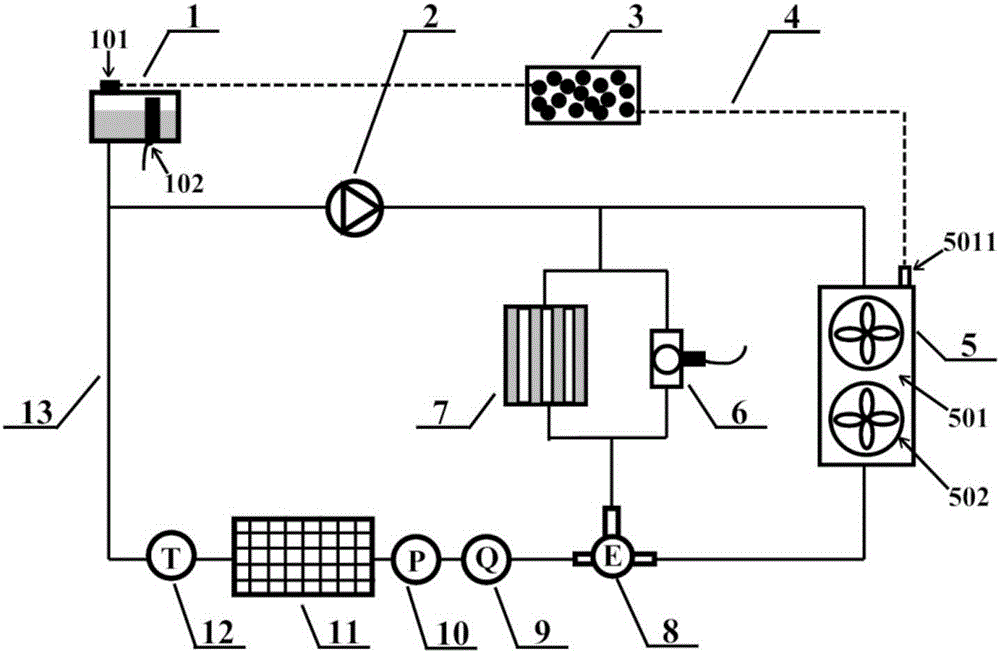

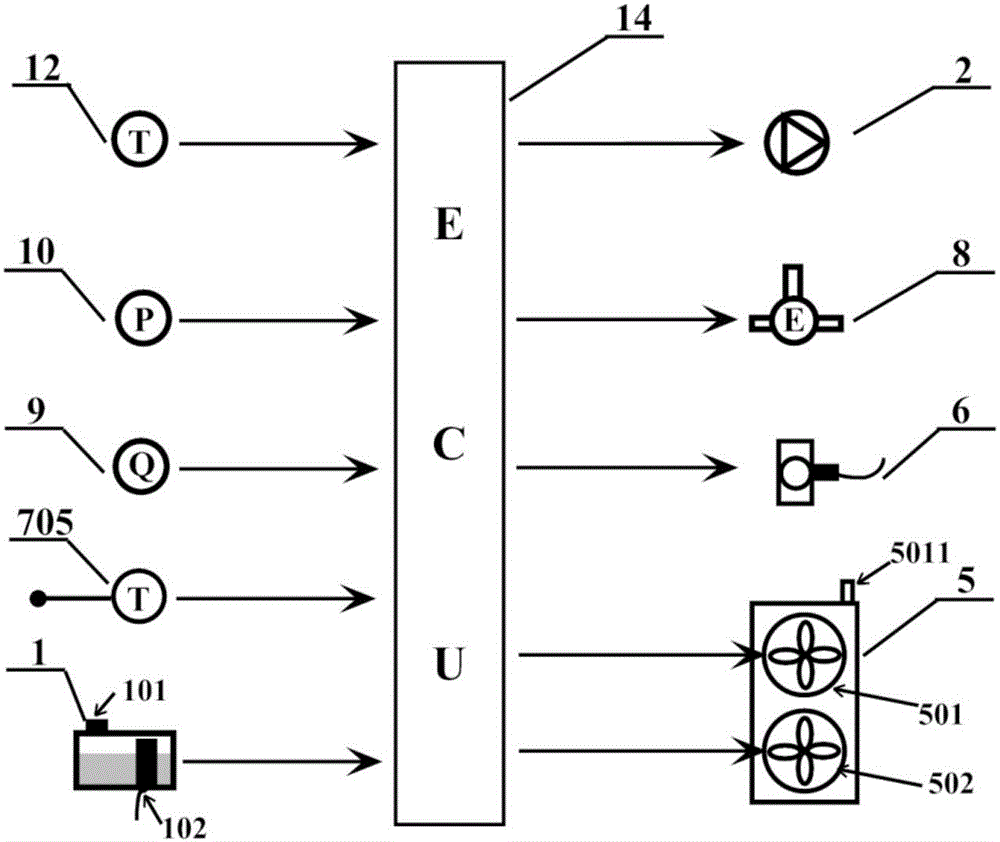

[0032] Such as figure 1As shown, the thermal management system and control method of the fuel cell with heat storage heating function include a small circulation water system, a large circulation cooling system, a deionized water circulation system and a control system. The control system can be a controller ECU, or a control system with ECU as the core. In this embodiment, the controller is the controller ECU14.

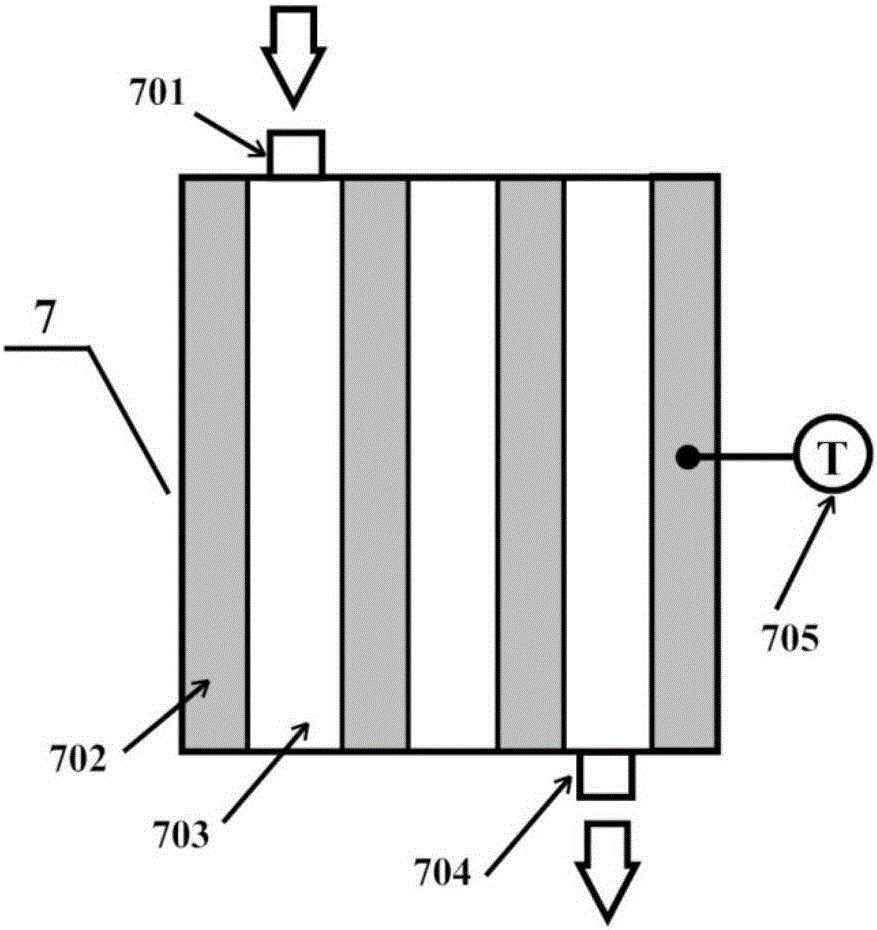

[0033] The function of the small circulating waterway system is to heat the fuel cell 11 at a low temperature and store heat for the heat accumulator 7, which is composed of an electronic water pump 2, a solenoid valve 6, a heat accumulator 7, an electronic thermostat 8, a flow meter 9, and a pressure sensor 10. Composed of a fuel cell 11, a temperature sensor 12 and a hard water pipe 13. Such as Figure 4 As shown, when the outlet temperature T of the fuel cell 11 is lower than the lower limit value Tmin of the optimum temperature range, the ECU 14 gives an inst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com