Solid oxide fuel cell stack array and power generation system thereof

A fuel cell stack, solid oxide technology, applied in solid electrolyte fuel cells, fuel cells, fuel cell grouping, etc., can solve the problems of difficult positioning and installation, no further details on how to set fasteners, and high size requirements. Achieve good and stable sealing and electrical conductivity, easy maintenance of pipelines and repairs, compact and centralized structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

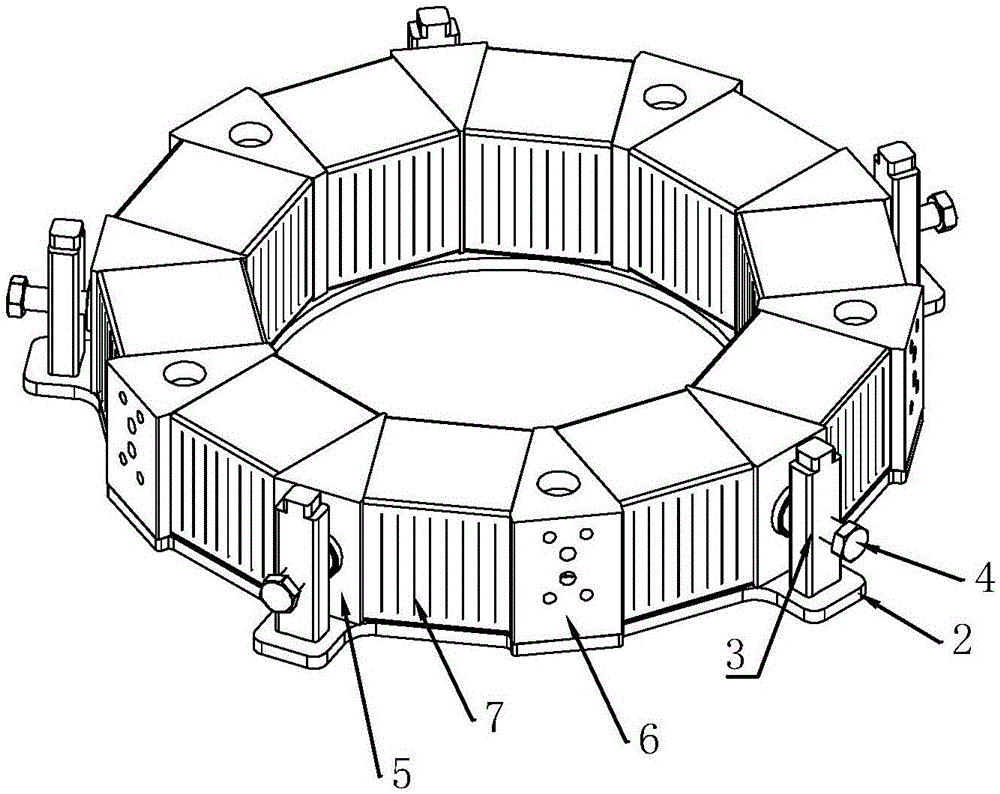

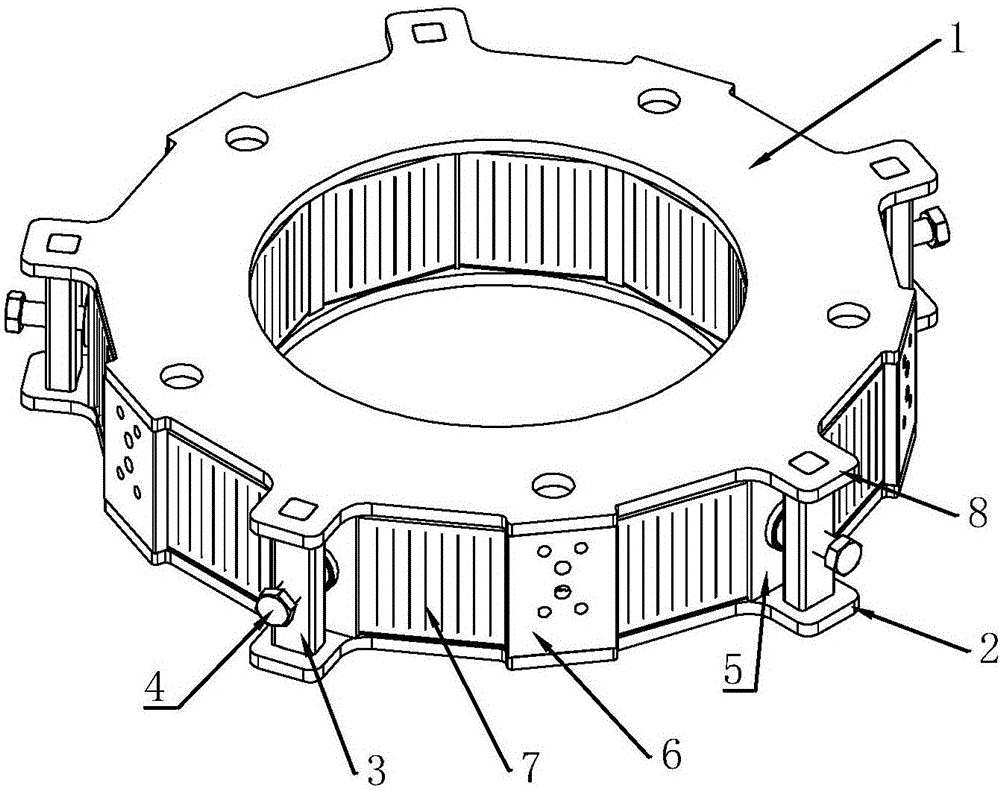

[0042] A solid oxide fuel cell stack array shown in this embodiment includes 10 cell stacks, and also includes an upper tray 1, a lower tray 2, a support column 3, a force screw 4, a movable block 5, a fixed block 6, and a cell stack 7 and other main components.

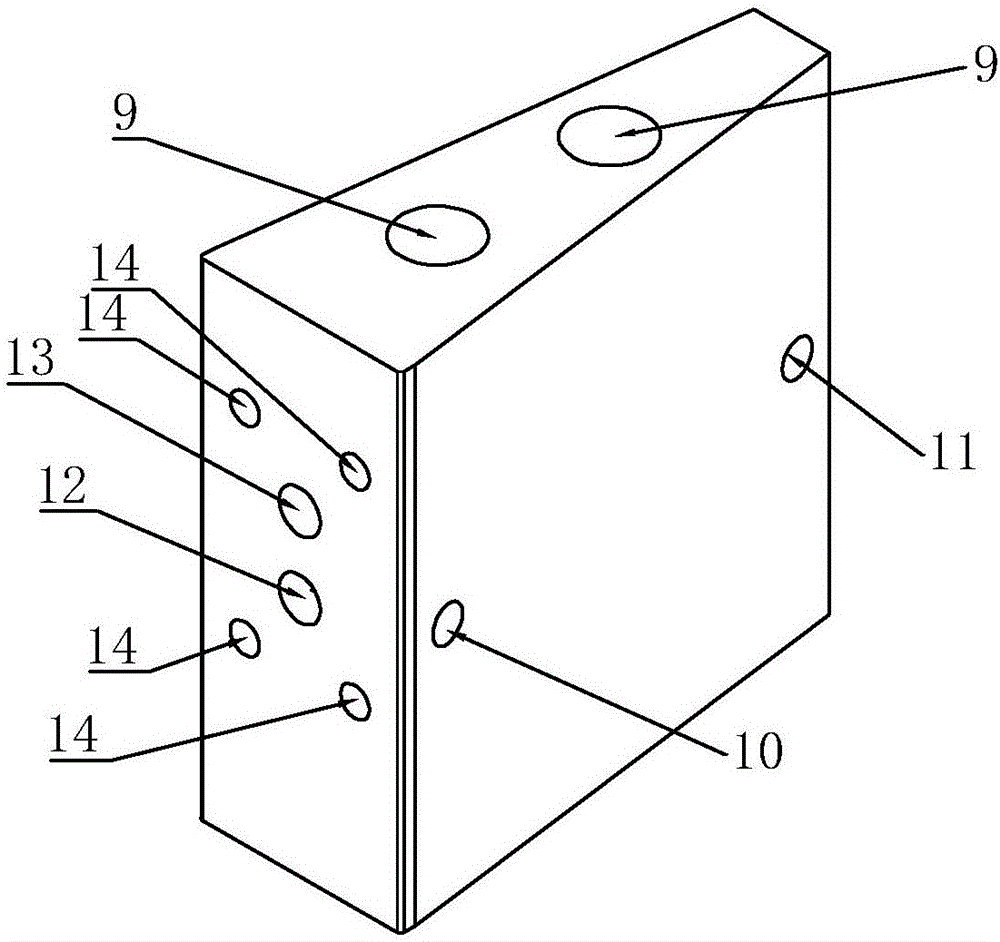

[0043] Such as figure 1 As shown, the battery stack group including 10 battery stacks 7 is placed on the lower tray 2, the battery stack 7 is in a horizontal shape, and the two sides of the battery stack 7 are respectively movable blocks 5 and fixed blocks 6, which are usually adjacent to each other in order to facilitate installation and use. A movable block 5 is set in the middle of the battery stack 7, and fixed blocks 6 are respectively set on both sides of the adjacent battery stack 7, so that the battery stacks 7 are arranged in sequence to form a layered annular distribution. As a preference, the horizontal section of the movable block 5 and the fixed block 6 is presented. Isosceles trapezoidal, the outer sur...

Embodiment 2

[0051] The battery stack array shown in this embodiment contains 4 battery stacks, including main components such as an upper tray 1 , a lower tray 2 , a support column 3 , a force screw 4 , a movable block 5 , a fixed block 6 , and a battery stack 7 .

[0052] Such as Figure 8 with Figure 9 As shown, 4 battery stacks are placed on the lower tray 2, and the two sides of the battery stack 7 are respectively movable blocks 5 and fixed blocks 6, on which there is an upper tray 1, and there is a support column 3 between the upper tray 1 and the lower tray 2, supporting A force screw 4 is arranged on the column 3 . When pressurizing, rotate the force-applying screw 4, and the force-applying screw 4 pushes the movable block forward, and the movable block 5 exerts pressure on the battery stacks 7 on both sides during the advancing process, so as to achieve the purpose of pressurizing the battery stack. The materials of the upper tray, the lower tray, the support column, the force...

Embodiment 3

[0056] In this embodiment, the cell stack pressurization structure in the SOFC power generation system is as follows Figure 11 As shown, it includes an upper tray 1, a lower tray 2, a support column 3, a force screw 4, a movable block 5, a fixed block 6, a battery stack 7 and other main components.

[0057] Such as Figure 11 As shown, seven battery stacks are placed on the lower tray 2, and the two sides of the battery stack 7 are respectively movable blocks 5 and fixed blocks 6, on which there is an upper tray 2, and there is a support column 3 between the upper tray 1 and the lower tray 2, supporting A force screw 4 is arranged on the column 3 . When pressurizing, rotate the force-applying screw 4, and the force-applying screw 4 pushes the movable block 5 forward, and the movable block 5 exerts pressure on the battery stacks 7 on both sides during the advancing process, so as to achieve the purpose of pressurizing the battery stack 7. The upper tray 1, the lower tray 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com