Copper aluminum interface alloy composite conductor internal wave tube used in tubular bus duct

A technology of composite conductors and tubular busbars, which is applied to the installation of metal/alloy conductors, single-tube conductors, and busbars. It can solve problems such as inability to make full use of electric energy, low heat dissipation performance of loads, and unfavorable energy saving, and achieve good heat dissipation. Convection function, better heat dissipation performance, and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

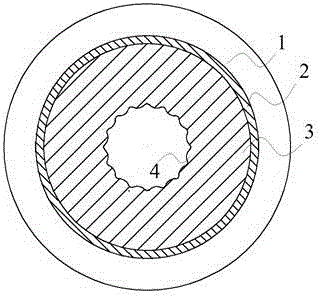

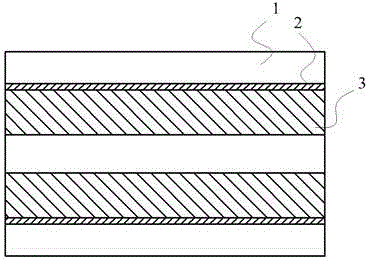

[0035] A copper-aluminum interface alloy composite conductor internal wave tube used in tubular bus ducts, such as figure 1 and figure 2 As shown, it includes an aluminum pipe 3 and a copper pipe 1 set outside the aluminum pipe. The side wall where the inner diameter of the aluminum pipe 3 is located is provided with several convex and concave waves 4 . The conductance of the inner wave expansion area of the inner wave tube busbar is synchronized with the conductance of the outer surface. The efficient auxiliary section carries a large current, and the load heat dissipation performance is better.

[0036] Further requirements are made on the performance of the conductor to ensure the performance of the inner wave tube of the conductor. In one specific embodiment, the copper pipe 1 is a copper material of GB / T5231 national standard, and the copper content is not less than 99.9%. Made of. Further preferably, the aluminum pipe 3 is made of GB / T1196 national standard aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com