Method of functionalizing surfaces of carbon nanomaterials

A technology of carbon nanomaterials and surface functionalization, applied in the direction of multi-walled carbon nanotubes, chemical instruments and methods, nanotechnology, etc., can solve problems such as consumption, difficulty in implementation, and large solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] experiment

[0056] Material

[0057] Multi-walled carbon nanotubes with an average diameter of 10 nm and an average length of 1.5 μm were purchased from Nanocyl, Belgium. The surface area is 250-300m 2 / g. Poly(vinylidene fluoride) (PVDF) powder was purchased from Alfa Aesar. Solvents used, including analytical grade ethanol, acetone, chloroform and N,N-dimethylformamide (DMF) were purchased from Sigma Aldrich.

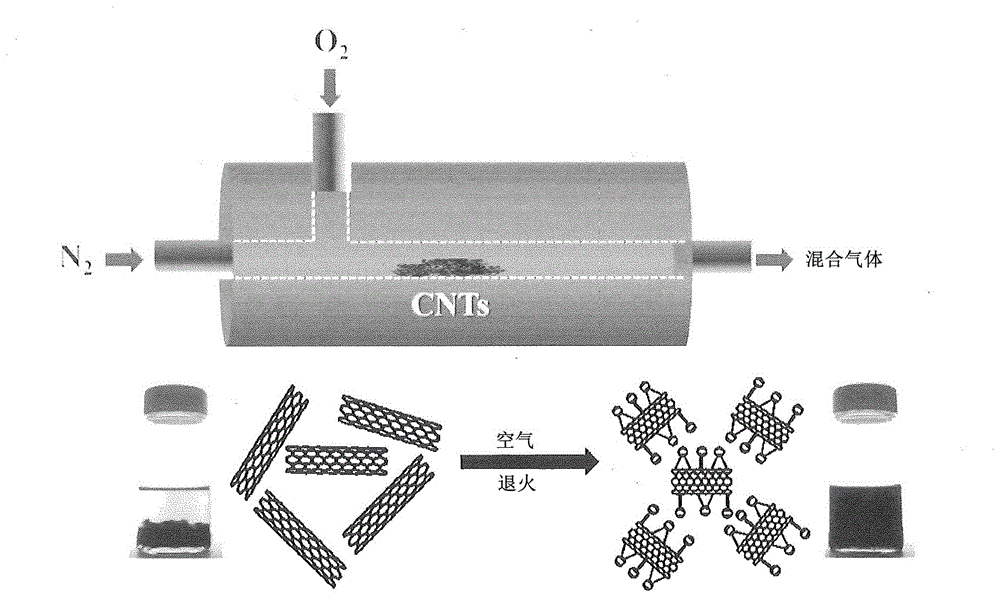

[0058] Air annealing

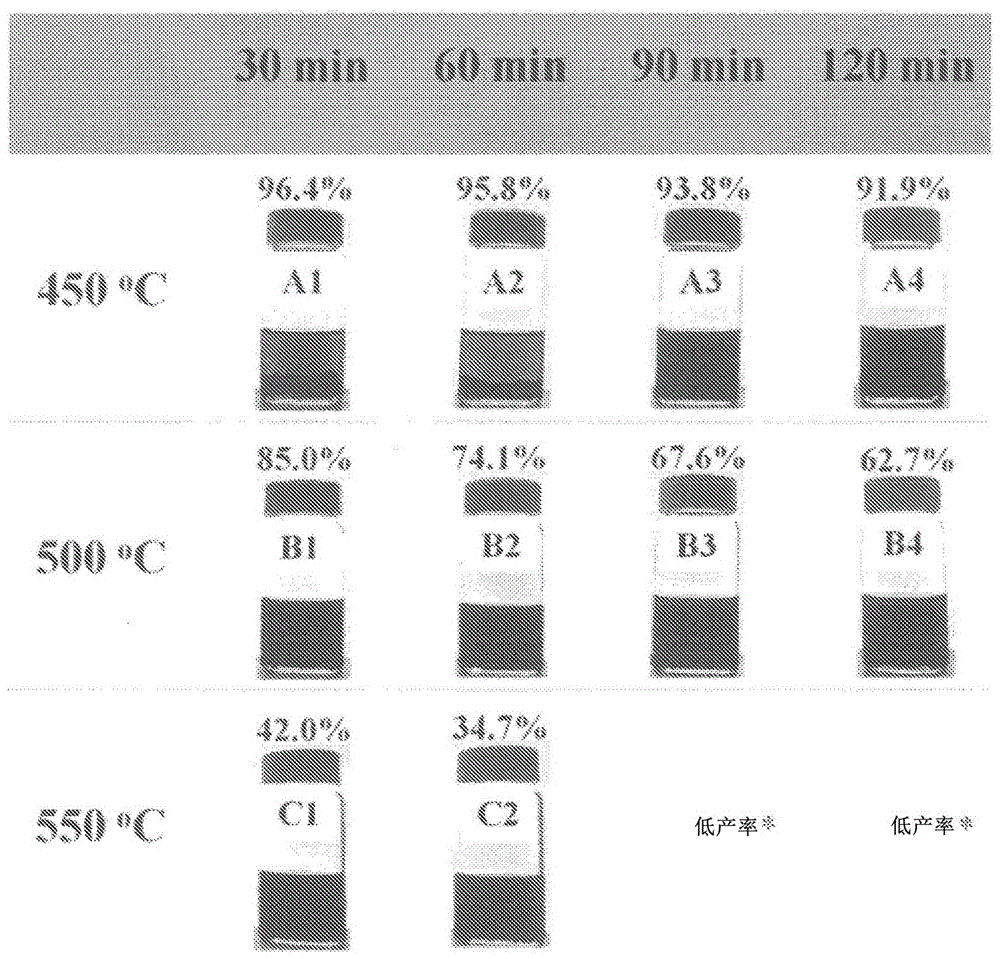

[0059] The annealing process was carried out in a thermogravimetric analyzer (Q 500, TA Instruments). Pristine CNTs without any pretreatment were placed in a platinum boat and heated to a preset temperature between 450 °C and 550 °C at a rate of 5 °C / min under an air flow rate of 5 ml / min. Use N with an instantaneous flow rate of 50ml / min 2 , as preliminary experiments indicated that dilution is required to achieve a controlled surface oxidation reaction of CNTs. A schematic diagram of the process is in figure 1 shown in . For ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com