Process for biochemical denaturation of an asbestos-containing material

一种石棉、酸性溶液的技术,应用在发酵等方向,能够解决变性困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Example 1: Liquid / Solid Waste from Vinegar Production

[0066] Residual microbial growth and fermentation of the waste from the vinegar production is carried out by incubating the waste in water and in the presence of woody material from the vine leaves used for wine vinegar production. The temperature for microbial growth and fermentation was 15-25°C and the time range was 24-48 hours. Acids, especially acetic and tartaric acids, are formed during this step. Thus, an acidic solution / suspension is obtained with a pH of 0-6, preferably 2, also depending on the amount of sugar-containing nutrients that can or must be added to the solution to increase the metabolic activity of extreme acidophilus and acidophilus and quality.

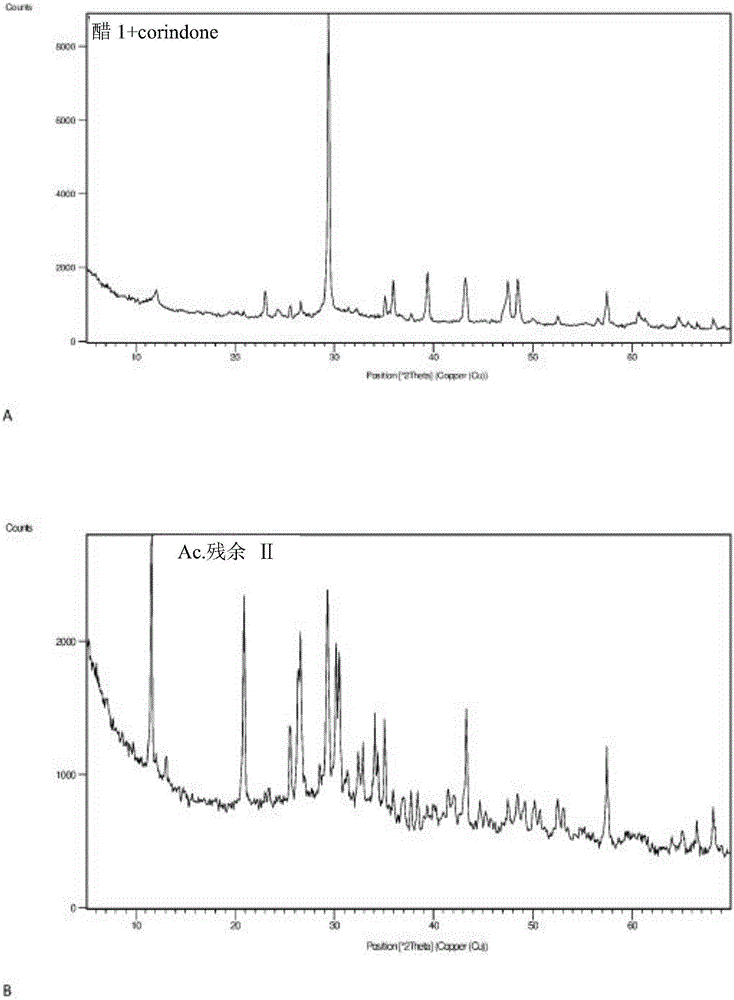

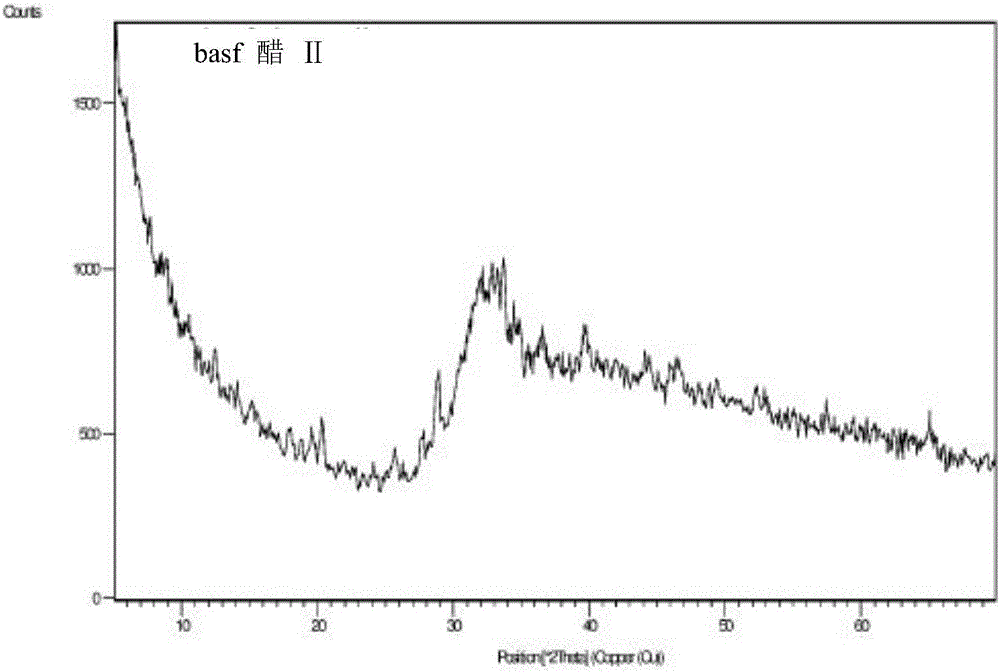

[0067] 10 grams of asbestos cement powder was mixed with 100 ml of an acidic solution derived from the fermentation of grape leaves for wine vinegar production at 125°C-170°C and 5-9 bar for 14-20 hours. At the end of the reaction, complete conver...

Embodiment 2

[0076] Example 2: Waste from wine production

[0077] Mixed bacterial and fungal fermentation is carried out by incubation of liquid / solid waste (pomace) in water, preferably at a temperature of 15 to 25° C. for a time ranging from 24 to 48 hours. Acids, especially acetic and tartaric acids, are formed during this step. Thus, an acidic solution / suspension is obtained with a pH of 0-6, preferably 2, also depending on the amount of sugar-containing nutrients that can or must be added to the solution to increase the metabolic activity of extreme acidophilus and acidophilus and quality.

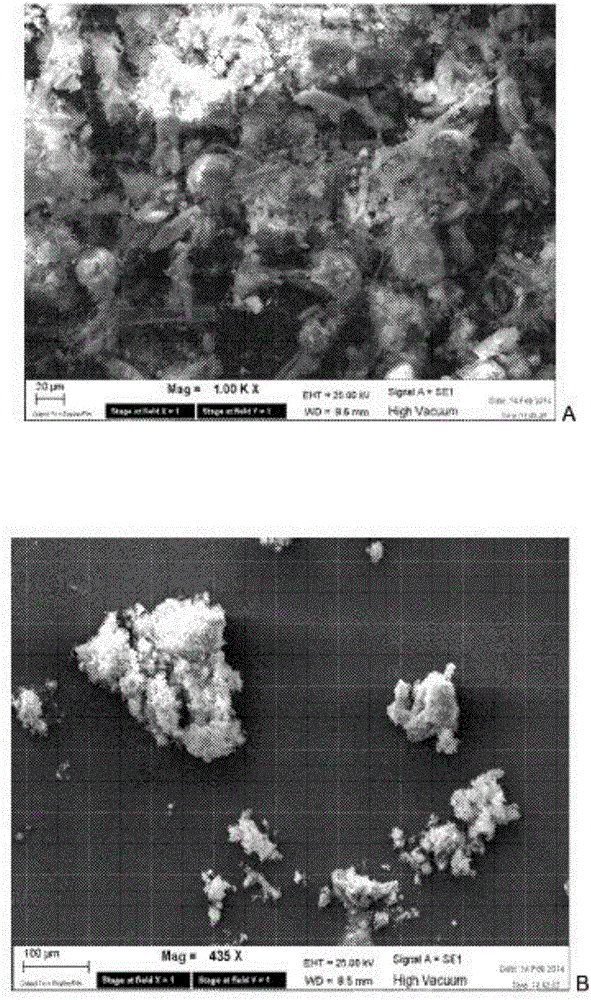

[0078] Mix 10 g of asbestos cement powder with 100 ml of liquid / solid waste derived from solutions used for pomace fermentation, wine and / or gran production and react at 125°C-170°C and 5-9 bar for 14- 20 hours. At the end of the reaction, complete conversion of asbestos and formation of new minerals were observed, such as Figure 4 and Figure 5 shown.

[0079] Figure 4 shows the initial...

Embodiment 3

[0087] Example 3: Processing waste from a tannery

[0088] Residual microorganisms from tannery processing waste are grown and fermented by incubating liquid / solid waste in water. The temperature for microbial growth and fermentation was 15 to 25°C and the time range was 8-24 hours. During this step, acids, especially acetic acid, are formed. Thus, an acidic solution / suspension is obtained with a pH of 0-6, preferably 2, also depending on the amount of sugar-containing nutrients that can or must be added to the solution to increase the metabolic activity of extreme acidophilus and acidophilus and quality.

[0089] 10 g of asbestos cement powder are mixed with 100 ml of an acidic solution obtained from fermentation of water used for scalding tomato skins and allowed to react for 14-20 hours at 125-170° C. and 5-9 bar. At the end of the reaction, complete conversion of asbestos and formation of new minerals were observed, such as Figure 7 and Figure 8 shown.

[0090] F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com