Method for obtaining an indication, in particular a starting indication of a possible faulty load condition of a multi-phase electric motor

A technology for multi-phase motors and load conditions, applied in the direction of motor control, measuring electricity, electrical components, etc., can solve problems such as insufficient protection, time delay of overheating identification devices, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

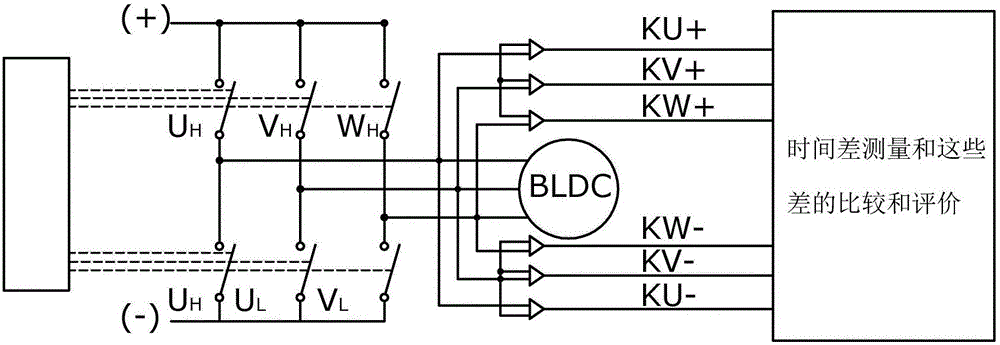

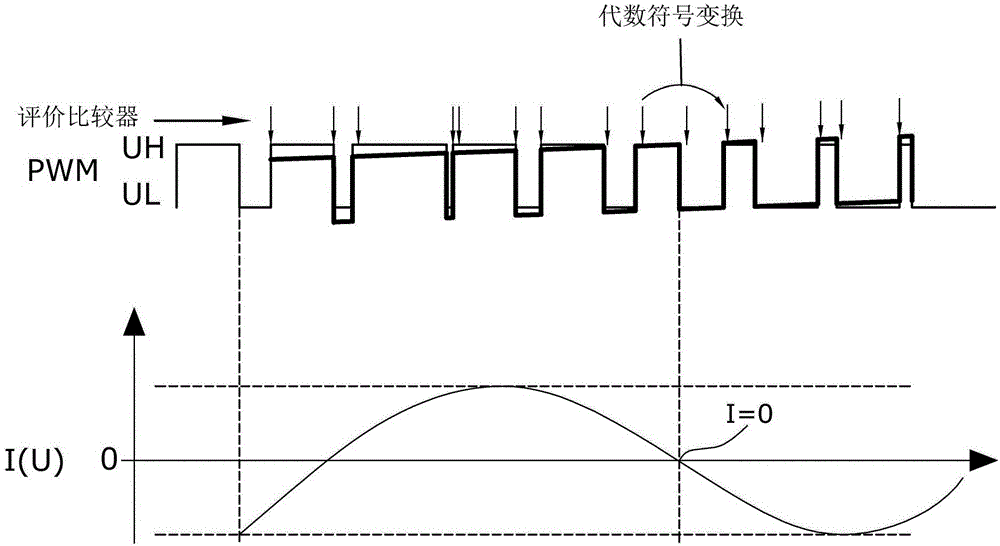

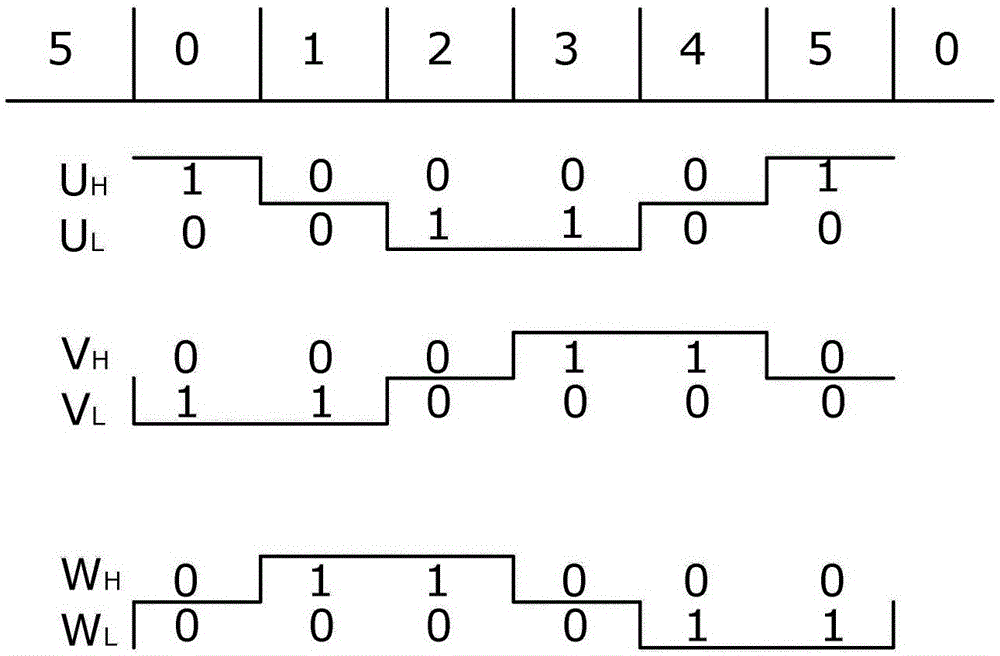

[0146] The invention is based on the insight that when driving an inductive load such as a motor, a comparator is used to determine whether a transistor has a positive voltage drop (under load) or a negative voltage drop (in the case of inductive feedback) in the on-state case).

[0147] This is an indication of the direction of current flow through the driver (switch). In the case of an inductive load such as a motor, the point in time at which the current direction is reversed is of course determined on the one hand by the control of the modulation motor, but also on the other hand by the behavior of the coil current which is known to follow the modulation voltage. The expected value for when the transition from positive to negative voltage drop will occur (ie the current through the corresponding driver drops to zero) is predetermined by the PWM modulation of the motor and the motor parameters.

[0148] If the position of the algebraic sign transformation of one terminal (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com