Control system for plate drawing part automatic production line

A technology of automated production lines and control systems, applied in the direction of manufacturing tools, presses, metal processing equipment, etc., can solve problems such as affecting the economic benefits of home appliance enterprises, unable to meet production needs, low processing efficiency, etc., to achieve station configuration and work procedures. Reasonable, reduce production costs and labor intensity, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

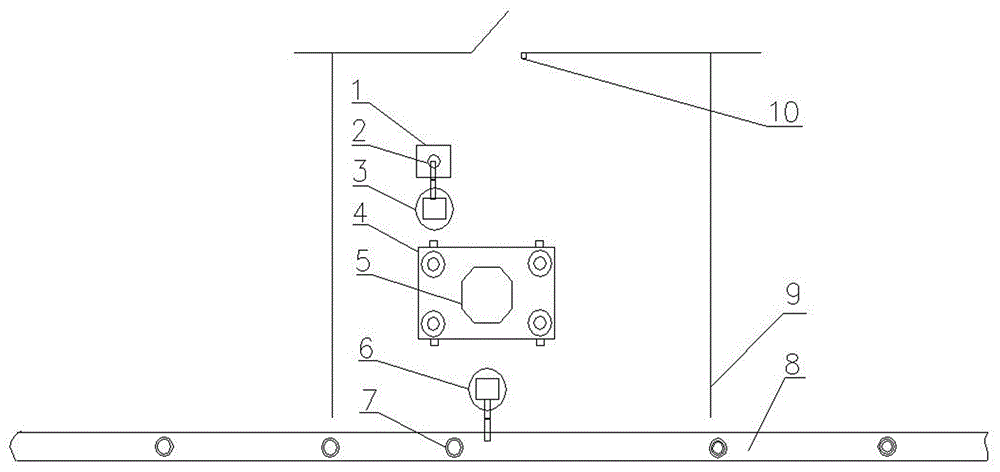

[0016] Such as figure 1 As shown, in the present invention, the automatic production line of plate drawing parts is centered on the plate drawing hydraulic machine 4, and the pneumatic sucker robot 3 absorbs the plate 2 from the plate storage platform 1 and then transfers it to the plate drawing mold 5 of the plate drawing hydraulic machine 4 After the processing is completed, the pneumatic clamp robot 6 transfers the processed sheet stretching finished product 7 from the sheet stretching hydraulic press 4 to the finished product conveyor belt 8 and transports it to a designated position. Considering the safety of the equipment, an equipment safety wall 9 is installed on the periphery of the entire production line, and a safety door 10 is provided on the equipment safety wall 9 .

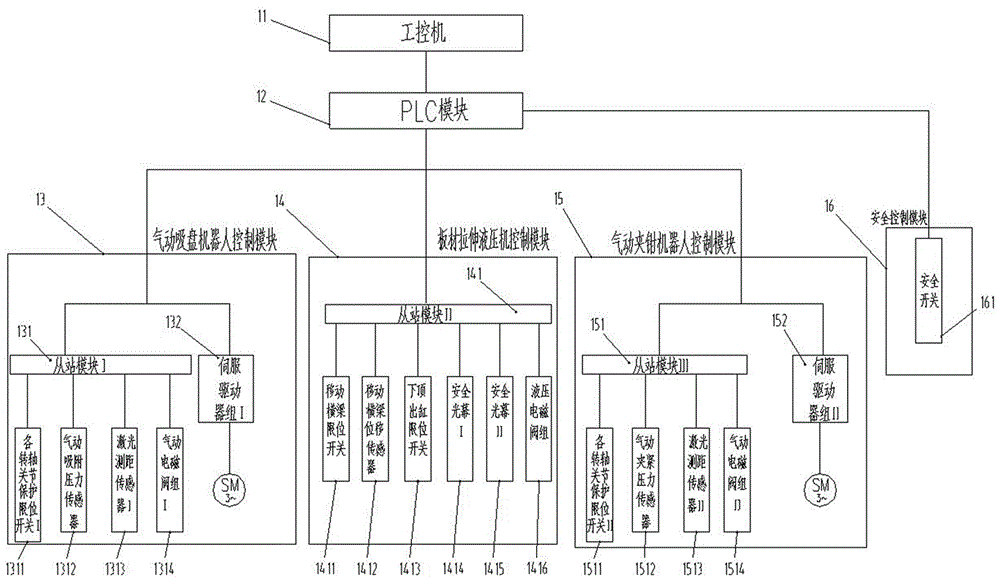

[0017] Such as figure 2 As shown, the control syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com