Preparation method for copper-indium-tellurium ultrathin regular semiconductor nanosheets

A technology of copper indium tellurium and nanosheets, which is applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of limited synthesis difficulty and insignificant results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

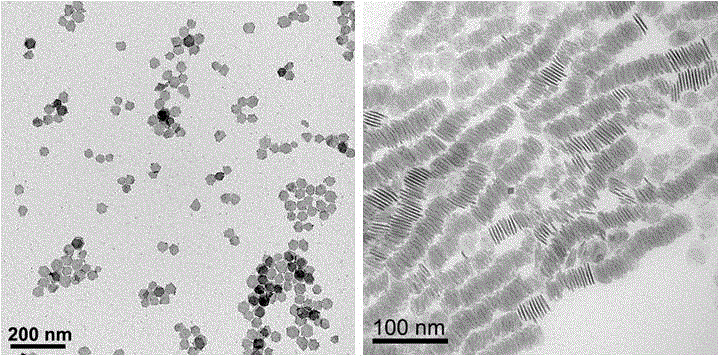

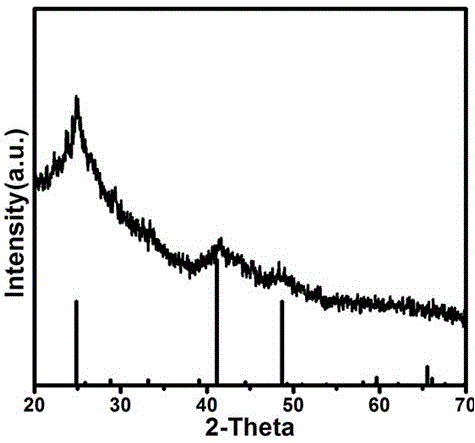

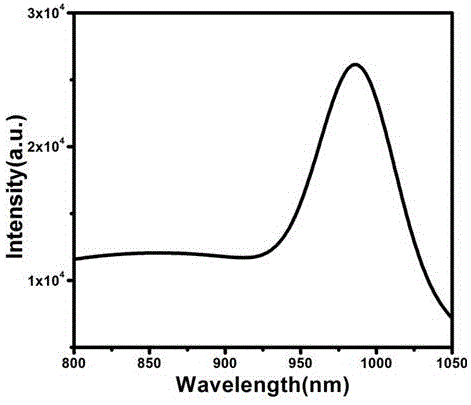

[0006] During operation, first weigh a certain amount of precursors of copper source and indium source, dissolve them in an eighteen-dilute solution adding a certain amount of surface ligands, and form an organic solution of about 0.02mol / L, and then degas and fill The mixed solution was heated to 90°C while alternating the inert gas. Weigh a certain amount of tellurium powder and add it into the organic solution to form a 0.5mol / L tellurium-containing organic solution, and promote the dissolution of the tellurium powder by heating, then add it to the previous mixed solution, and keep stirring. Then degas a certain amount of eighteen dilute solvent at 120°C, and then raise the temperature to a higher temperature, quickly inject the final mixed solution into the eighteen dilute solvent at high temperature, then stop the reaction, and quickly cool down At room temperature, ultrathin regular nanosheets of copper indium tellurium are obtained. The method of collecting copper indi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com