Monodisperse near-infrared silver telluride quantum dots and preparation method thereof

A quantum dot and near-infrared technology, applied in the field of material science, can solve the problems of poor stability of quantum dots and no near-infrared fluorescence emission, etc., and achieve the effect of mild and controllable reaction conditions, suitable for large-scale industrial production, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 Take 0.1mmol of tellurium powder and 0.3mmol of sodium borohydride and add them to 3mL of water, cut off the air and react for 30 minutes to obtain a clear and transparent aqueous solution of sodium telluride hydride; take 0.4mmol of silver nitrate and dissolve it in 35mL of oleylamine, and dissolve the sodium telluride hydride Add the aqueous solution into the silver nitrate solution, stir for 5 minutes, then add 5 mmol of 1-dodecanethiol, continue stirring for 10 minutes, transfer the above solution to a 50mL reactor, and conduct a hydrothermal reaction at 180°C for 0.5 hours. After the reaction is completed, naturally cool to At room temperature, the upper organic phase was washed with a large amount of ethanol, and the surface ligand was exchanged with mercaptopropionic acid to obtain Ag evenly dispersed in water. 2 Te quantum dots.

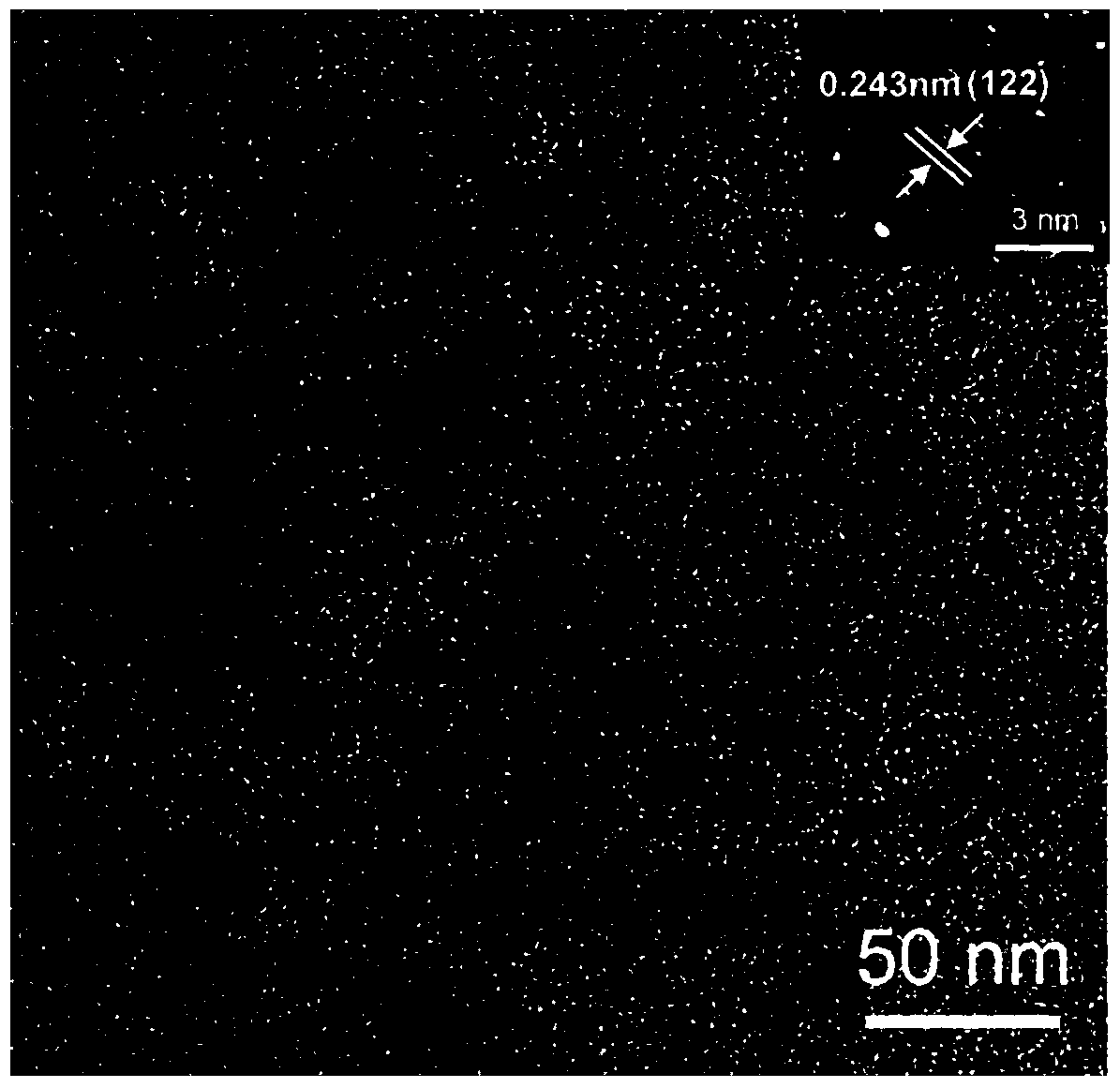

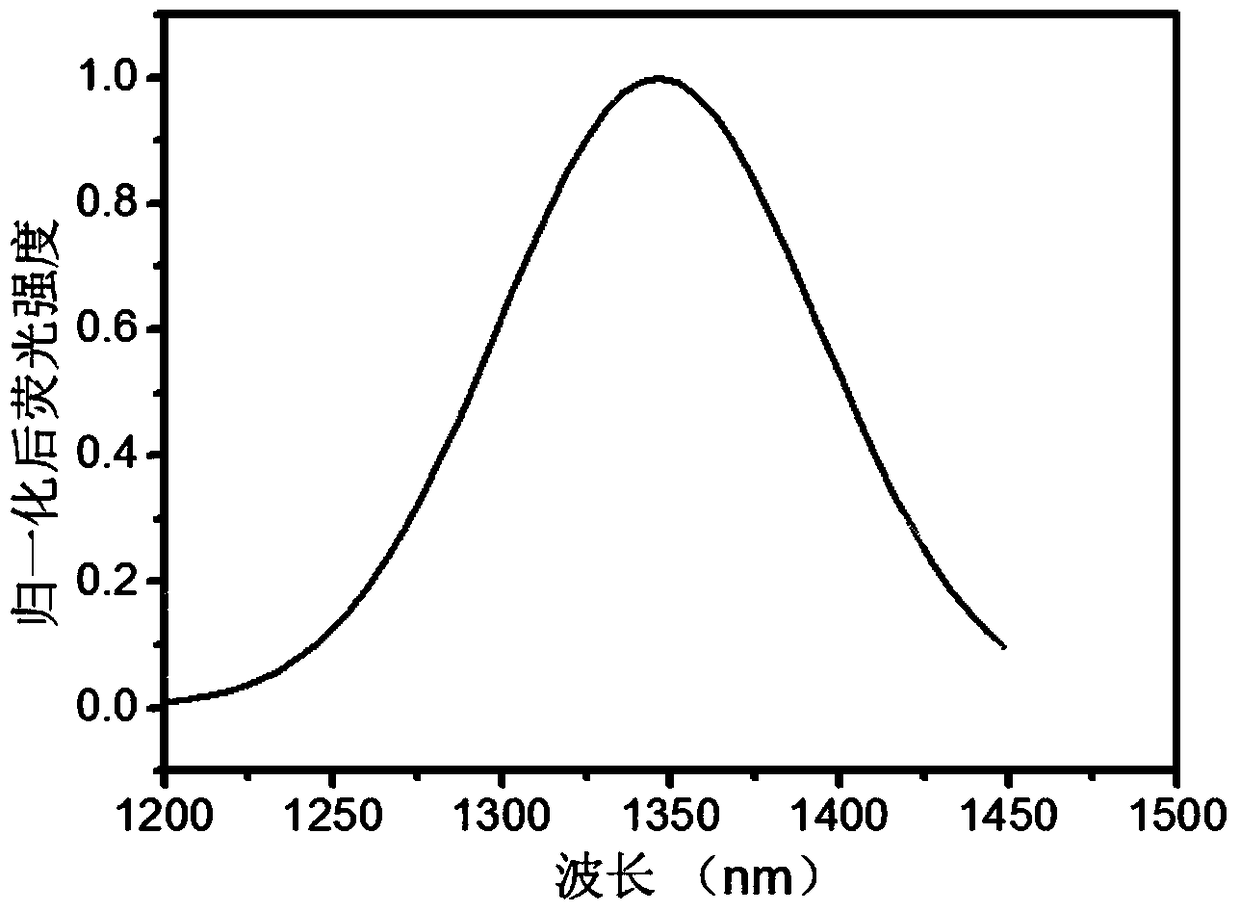

[0041] from figure 1 It can be seen from the transmission electron microscope photos that the near-infrared silver telluri...

Embodiment 2

[0042] Example 2 Take 0.1mmol of tellurium powder and 0.3mmol of sodium borohydride and add them to 2mL of water, cut off the air and react for 20 minutes to obtain a clear and transparent sodium telluride hydride solution; take 0.4mmol of silver acetate and dissolve it in 30mL of toluene, and dissolve the sodium telluride hydride solution Add silver nitrate solution, stir for 5 minutes, then add 5mmol tri-n-octyl phosphine, continue stirring for 10 minutes, transfer the above solution to a 50mL reaction kettle, and conduct a hydrothermal reaction at 200°C for 2 hours. After the reaction is completed, naturally cool to room temperature. After the upper organic phase was washed with a large amount of ethanol, the surface ligand was exchanged with mercaptopropionic acid to obtain Ag evenly dispersed in water. 2 Te quantum dots.

Embodiment 3

[0043] Example 3 Take 0.1mmol of tellurium powder and 0.3mmol of sodium borohydride and add them to 1mL of water, and react with the air for 10 minutes to obtain a clear and transparent sodium tellurium hydride aqueous solution; take 0.4mmol of silver lactate and dissolve it in 30mL of oleic acid, and dissolve the sodium tellurium hydride Add the aqueous solution to the silver nitrate solution, stir for 5 minutes, then add 5 mmol of cetyltrimethylammonium bromide, continue stirring for 10 minutes, transfer the above solution to a 50mL reactor, and conduct a hydrothermal reaction at 120°C for 24 hours, and the reaction is complete After natural cooling to room temperature, the upper organic phase was washed with a large amount of ethanol, and the surface ligand was exchanged with mercaptopropionic acid to obtain Ag evenly dispersed in water. 2 Te quantum dots.

[0044] In summary, the present invention prepares near-infrared silver telluride quantum dots by reacting at the two-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com