Vacuum suction cup mechanical handling device Sheet material handling device

A vacuum suction cup and handling device technology, applied in the field of machinery, can solve the problems of uneven placement of sheets, uncertain feeding position, and low processing efficiency, and achieve the effects of improving work efficiency, simple structure, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to illustrate the technical solution of the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0021] Such as Figure 1-4 Shown:

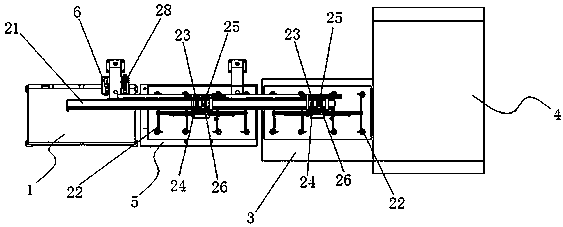

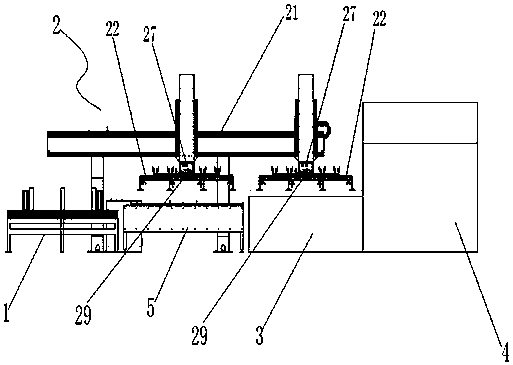

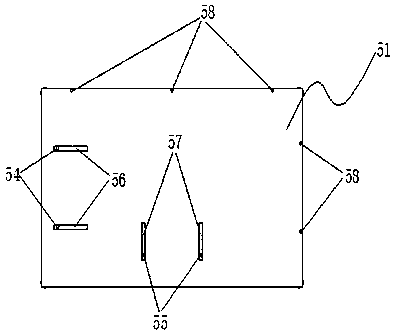

[0022] A vacuum suction cup manipulator sheet material handling device, comprising a feeding platform 1, a mechanical handling device 2, a working platform 3, a laser cutting machine 4, a positioning platform 5 and a compressed air storage 6.

[0023] Among them, the mechanical handling device 2 includes a mechanical frame body 21, a vacuum chuck manipulator 22, an x-axis servo motor 23, an x-axis reducer 24, a z-axis servo motor 25, a z-axis reducer 26, a vacuum solenoid valve 27, a vacuum pump 28 and a vacuum Pressure digital display 29, one end of the mechanical frame body 21 is located directly above the feeding platform 1, and the other end is located directly above the working platform 3; the x-axis servo motor 23 is connected to the x-axis re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com