A kind of anti-pillow effect flux and its preparation method and application

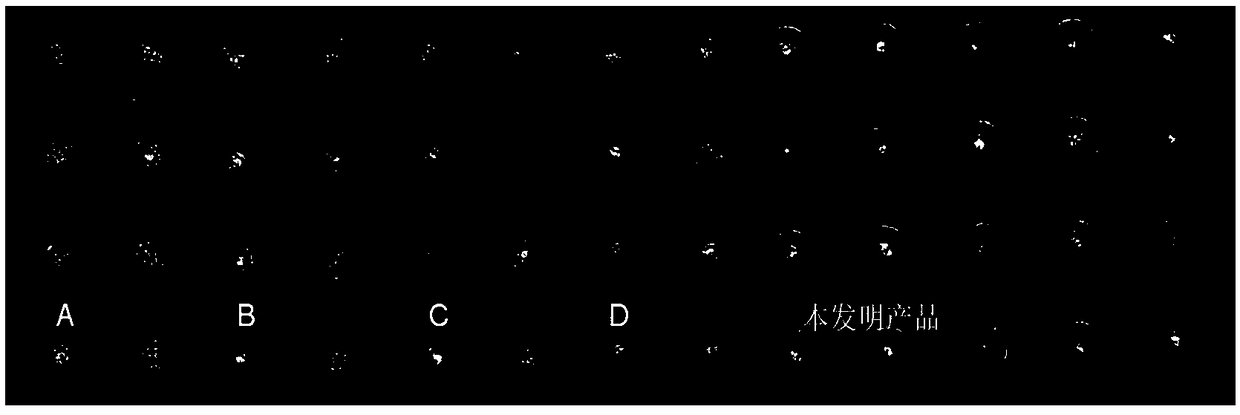

A flux and effect technology, which is applied in the field of anti-pillow effect flux and its preparation, can solve the problems of not preventing pillow effect, ignoring secondary oxidation, and not forming solder joints, etc., achieving excellent anti-pillow effect performance, wetting Good, bright solder joint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] An anti-pillow effect flux, which comprises the following components in mass percentage: 45% of unsaturated rosin resin, 35% of hexanediol, 13% of thixotropic agent, and 7% of succinic acid. Among them, the unsaturated rosin resin is made of the following components by mass percentage: modified rosin 18%, 1,2-propanediol 8%, ethylene glycol 8%, diethylene glycol 16%, styrene 35% %, acrylic acid 15%; the preparation method of the above-mentioned unsaturated rosin resin is as follows: melt the modified rosin and heat it to 240°C, then add acrylic acid, ethylene glycol, 1,2-propylene glycol, and diethylene glycol to mix and react while stirring , Then add styrene to mix and react while stirring, and cool down.

[0025] The preparation method of above-mentioned anti-pillow effect soldering flux comprises the following steps:

[0026] A, first pulverize the unsaturated rosin resin until the particle size of the unsaturated rosin resin is 0.3~0.50cm;

[0027] B. Add unsatur...

Embodiment 2

[0030] An anti-pillow effect flux, which comprises the following components by mass percentage: 30% of unsaturated rosin resin, 40% of dipropylene glycol methyl ether, 20% of thixotropic agent, 10% of oxalic acid . Among them, the unsaturated rosin resin is made of the following components by mass percentage: modified rosin 15%, 1,2-propanediol 9%, ethylene glycol 9%, diethylene glycol 18%, styrene 31% %, acrylic acid 18%; the preparation method of the above-mentioned unsaturated rosin resin is as follows: melt the modified rosin and heat it to 240°C, then add acrylic acid, ethylene glycol, 1,2-propylene glycol, and diethylene glycol to mix and react while stirring , Then add styrene to mix and react while stirring, and cool down.

[0031] The preparation method of above-mentioned anti-pillow effect soldering flux comprises the following steps:

[0032] A, first pulverize the unsaturated rosin resin until the particle size of the unsaturated rosin resin is 0.3~0.50cm;

[00...

Embodiment 3

[0036] An anti-pillow flux, which comprises the following components in mass percentage: 50% of unsaturated rosin resin, 25% of butanediol, 20% of thixotropic agent, and 5% of sebacic acid. Among them, the unsaturated rosin resin is made of the following components by mass percentage: modified rosin 16%, 1,2-propanediol 7%, ethylene glycol 7%, diethylene glycol 15%, styrene 38% %, acrylic acid 17%; the preparation method of the above-mentioned unsaturated rosin resin is as follows: melt the modified rosin and heat it to 240°C, then add acrylic acid, ethylene glycol, 1,2-propylene glycol, and diethylene glycol to mix and react while stirring , Then add styrene to mix and react while stirring, and cool down.

[0037] The preparation method of above-mentioned anti-pillow effect soldering flux comprises the following steps:

[0038] A, first pulverize the unsaturated rosin resin until the particle size of the unsaturated rosin resin is 0.3~0.50cm;

[0039] B. Add unsaturated ros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com