Optical polyester film

An optical polyester film and film technology, applied in optical components, chemical instruments and methods, applications, etc., can solve the problems of easy-adhesive layer stripes, low film surface, bubble point, etc., to improve bonding fastness and Adhesion, simple and easy operation, the effect of improving hardness and scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Synthesis of modified polyester:

[0042] 1000 moles of PTA terephthalic acid, 1000 moles of ethylene glycol, 300 moles of 4.4-dihydroxydiphenylsulfone, 50 moles of 4.4'-dihydroxybenzophenone, 50 grams of ethylene glycol antimony, 17.5 grams After the trimethyl phosphate is mixed and stirred evenly, it is added to the esterification kettle, and the air in the reaction kettle is completely replaced with nitrogen, then the temperature is raised to 235°C, the pressure is 250KPa, and the esterification begins. The esterification time is about 2.5 hours After the esterification is completed, the temperature is raised to 265°C, a vacuum is established, the pressure is less than 40Pa, the polycondensation time is about 2 hours, and the intrinsic viscosity of the slice is 0.665dl / g.

[0043]Pure PET polyester chips were evenly mixed with polyester masterbatch chips with an average particle size of 2.00 μm, wherein the content of 2.00 μm silicon dioxide in the total polyester ch...

Embodiment 2~12

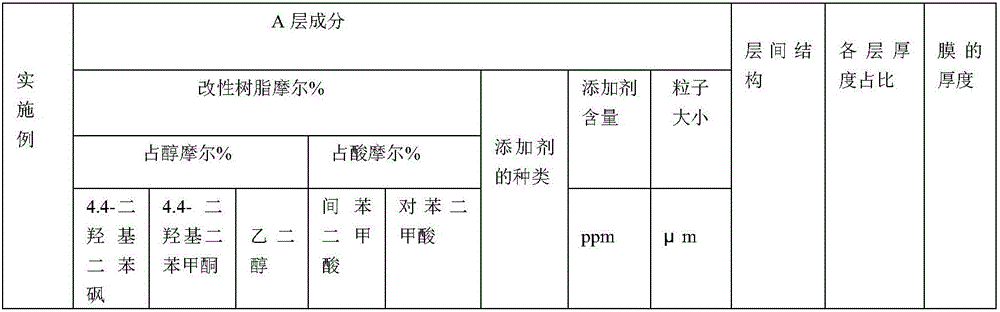

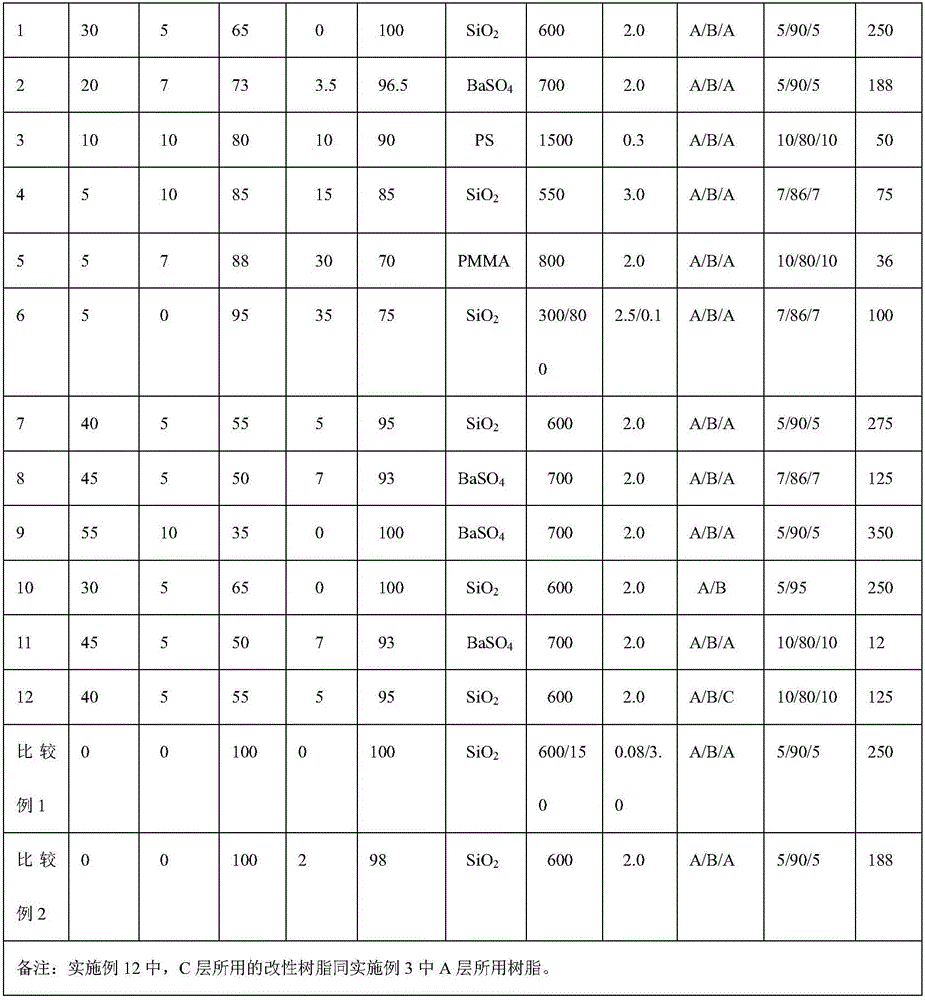

[0047] With the preparation method similar to Example 1, according to the composition of A and C polyester components in Table 1, the composition, particle size and content of additives, and the composition of B layer polyester components and additives in Table 2, different thicknesses were prepared. Optical Mylar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity value | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com