A plastic back door structure

A technology for back doors and plastics, applied in doors, vehicle parts, transportation and packaging, etc., can solve the problems that the weight reduction potential of the door structure is not fully tapped and the weight is large, and achieve a balance between economy and safety, and reduce weight , The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

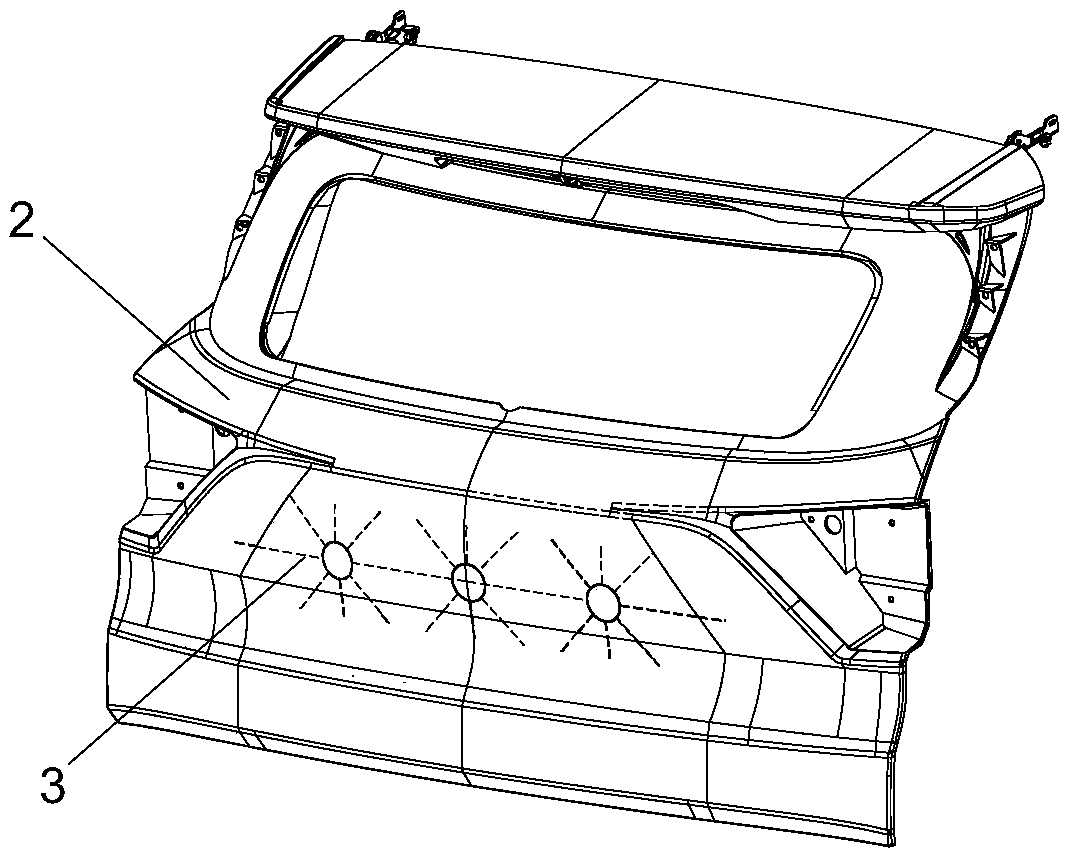

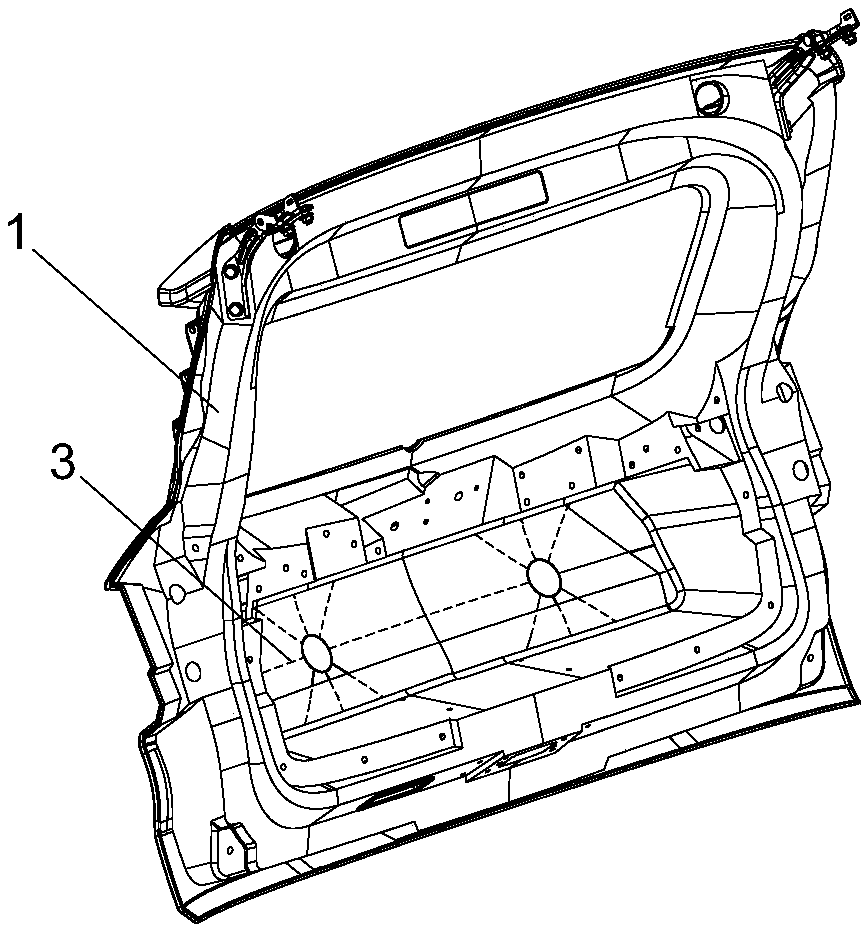

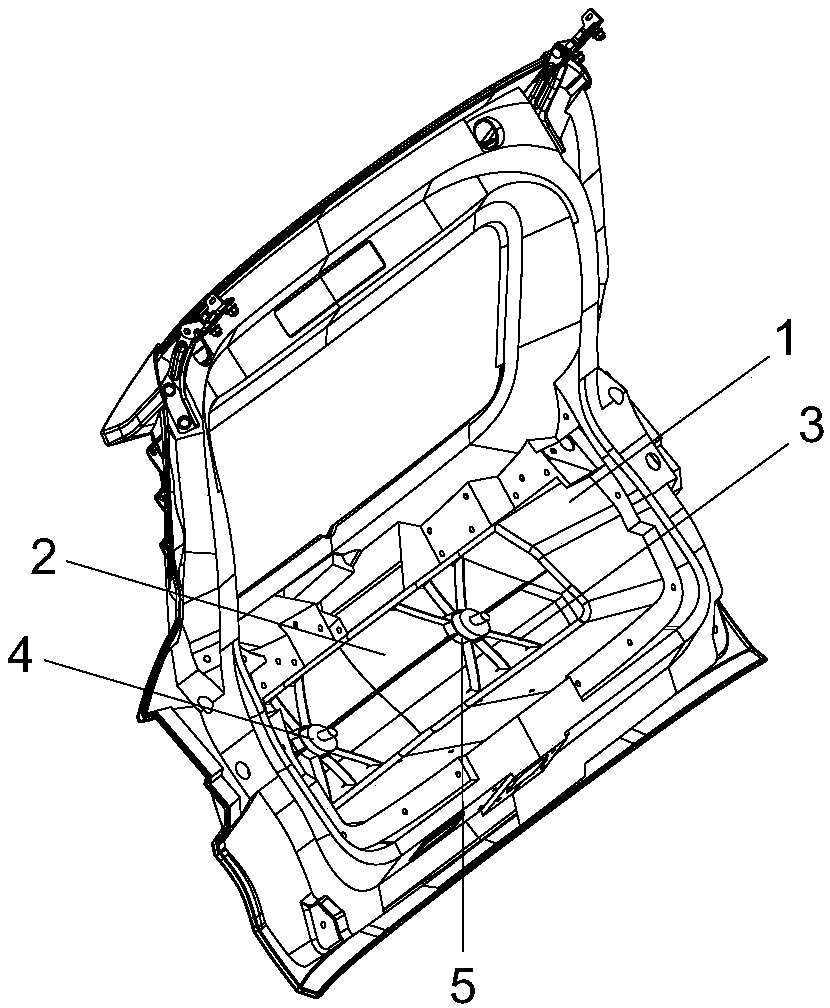

[0028] Such as figure 1 , Figure 4As shown, a plastic back door structure is located at the tail of the car. The plastic back door structure includes a back door inner panel body 1 and a back door outer panel body 2, a decorative panel on the back door, a back door left / The right decorative panel is integrally injection-molded on the back door inner panel body 1, the spoiler and the tail light box are integrated on the back door outer panel body 2, the back door inner panel body 1 and the back door outer panel body 2 are both It is made of plastic and fixed as a whole. A small amount of sheet metal reinforcing plates are also arranged on the back door inner panel body 1 and the back door outer panel body 2 to install the back door lock, air pressure strut, wiper motor, back door Rigid components such as door hinges. A reinforcing structure is provided between the back door inner panel body 1 and the back door outer panel body 2. The reinforcing structure includes a rib pl...

Embodiment 2

[0031] Such as figure 2 , image 3 As shown, the distribution area of the rib plate is two, and the rib plate 3 on the back door outer panel body 2 forms twelve rib grooves in groups of two, and the rib groove is connected with the inner panel body 1 of the back door. The positions and numbers of the reinforcing rib plates 3 correspond to each other, and the reinforcing rib plates 3 on the back door inner panel body 1 are adapted to be inserted in the reinforcing rib grooves. Buffer 4 is a spring buffer. All the other are with embodiment 1.

Embodiment 3

[0033] The stiffeners 3 are distributed in grid form. There is no buffer 4 in the gap between the back door inner panel body 1 and the back door outer panel body 2 . All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com