Pure-cotton fabric high-pressure water-saving jet dyeing sewage recovery system

A technology of jet dyeing and sewage recycling, applied in the textile field, can solve the problems of environmental pollution, waste of water resources, non-environmental protection, etc., and achieve the effects of high purification degree, high production efficiency, and water conservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The present invention also provides a method for treating jet dyeing wastewater by adopting the above-mentioned high-pressure water-saving jet dyeing sewage recovery system for all-cotton fabrics, and the specific steps are as follows:

[0023] Add chlorine dioxide to the disinfection tank, add coagulant to the coagulation tank, and add activated carbon to the adsorption tank. Dyeing sewage is first discharged into the filter tank. The grille in the filter tank will remove the yarn ends and cloth pieces in the dyeing sewage. The dyeing sewage flows from the filter tank into the disinfection tank. The chlorine dioxide in the disinfection tank disinfects and sterilizes the harmful substances in the dyeing sewage. The disinfected dyeing sewage enters the coagulation tank through the disinfection tank, and the coagulant in the coagulation tank will The dye and detergent in the dyeing sewage are combined into large particles to be removed, and then the dyeing sewage flows from t...

Embodiment 2

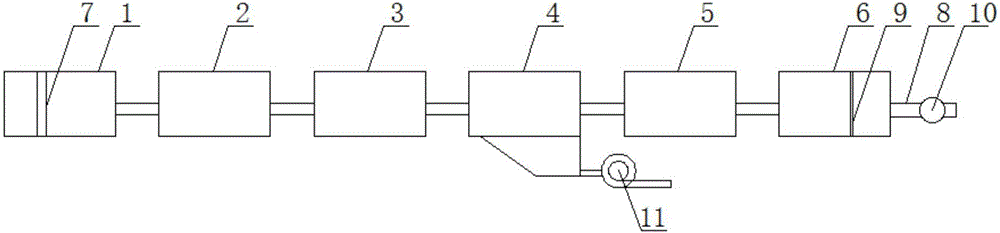

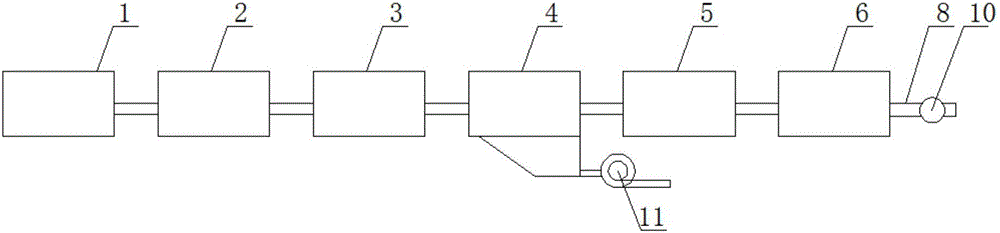

[0026] The invention discloses a high-pressure water-saving spray dyeing sewage recovery system for all-cotton fabrics, which includes: a filter tank, a disinfection tank, a coagulation tank, a sedimentation tank, an adsorption tank, a micro filter tank, and a grid is fixed in the filter tank The disinfection tank is connected to the filter tank through a pipeline, the coagulation tank is connected to the disinfection tank through a pipeline, the sedimentation tank is connected to the coagulation tank through a pipeline, and the adsorption tank It is connected to the sedimentation tank through a pipeline, the microfiltration tank is connected to the adsorption tank through a pipeline, a drainage pipe is fixed on the microfiltration tank, and a filter screen is installed in the microfiltration tank. Install a drain valve on the drain pipe described.

[0027] Preferably, a sludge pump is fixed at the bottom of the sedimentation tank.

[0028] Preferably, the grille is made of stainl...

Embodiment 3

[0033] The invention discloses a high-pressure water-saving spray dyeing sewage recovery system for all-cotton fabrics, which includes: a filter tank, a disinfection tank, a coagulation tank, a sedimentation tank, an adsorption tank, a micro filter tank, and a grid is fixed in the filter tank The disinfection tank is connected to the filter tank through a pipeline, the coagulation tank is connected to the disinfection tank through a pipeline, the sedimentation tank is connected to the coagulation tank through a pipeline, and the adsorption tank It is connected to the sedimentation tank through a pipeline, the microfiltration tank is connected to the adsorption tank through a pipeline, a drainage pipe is fixed on the microfiltration tank, and a filter screen is installed in the microfiltration tank. Install a drain valve on the drain pipe described.

[0034] Preferably, a sludge pump is fixed at the bottom of the sedimentation tank.

[0035] Preferably, the grille is made of stainl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com