Method for producing stain-bleeding porcelain tile

A technology for porcelain tiles and infiltration, applied in the field of architectural ceramics, can solve the problems of increasing the three-dimensional effect of printed patterns, performance limitations of infiltrated porcelain tiles, single color of infiltrated porcelain tiles, etc., and achieves a clear pattern and texture effect. The effect of increasing the thickness and increasing the amount of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A preparation method for bleed porcelain tiles, comprising the following steps:

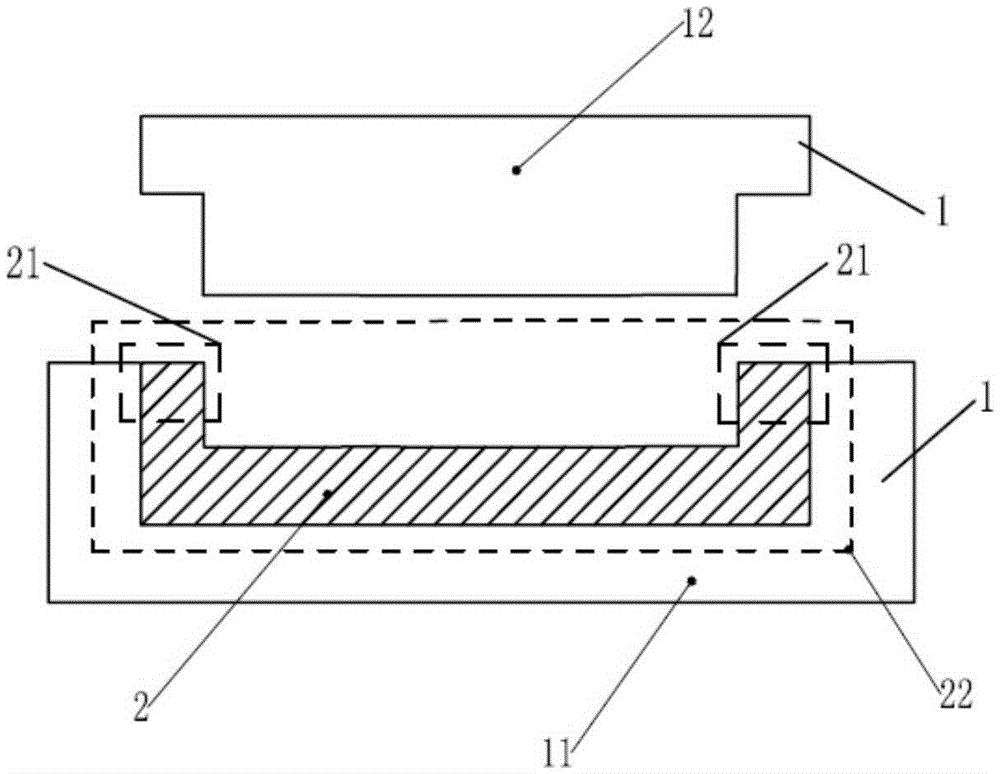

[0025] A, the powder is laid in the mold cavity of the lower mold 11 of the stamping die 1, and the green body 2 with the structure of the surrounding ring 21 is obtained by punching and pressing the upper mold 12, and the stamping surface of the upper mold 12 is provided with a boss, The area of the boss is smaller than the cloth area of the mold cavity of the lower mold 11, the surrounding ring 21 surrounds the surface of the blank 2 to form a cloth cavity 22, and the blank 2 is transferred for standby;

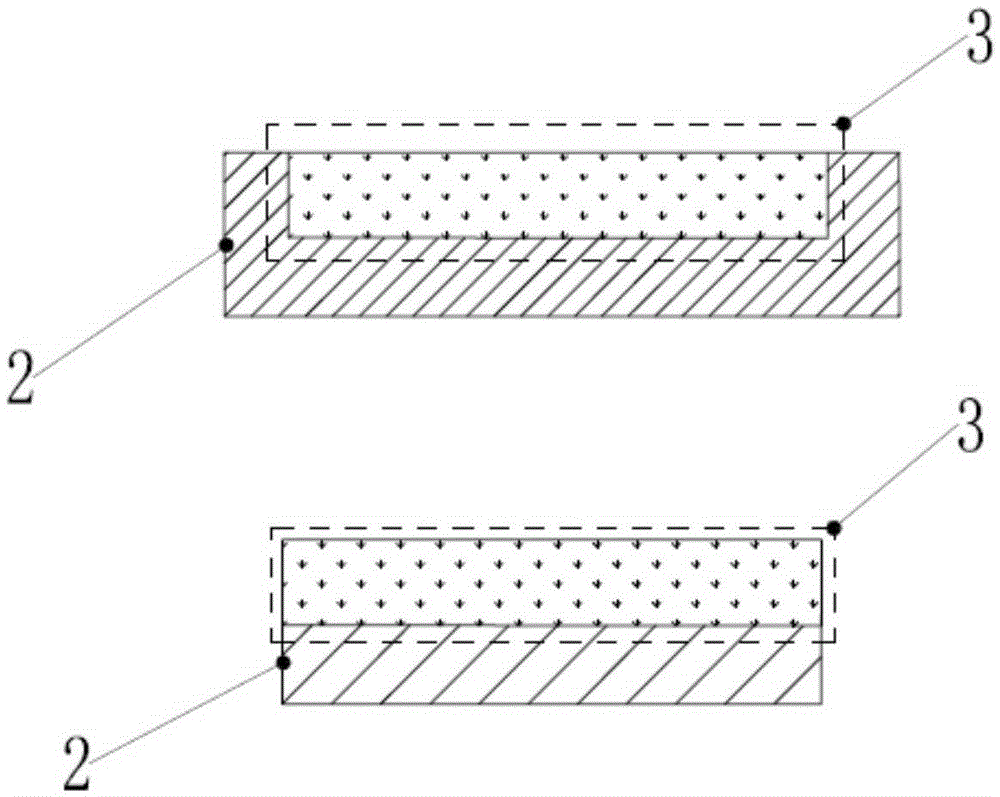

[0026] B. After drying the green body 2 obtained in step A, evenly spread the dough into the cloth cavity 22 to form the decorative layer 3;

[0027] C. Print the water-soluble bleed ink on the surface of the batter body 2 according to the designed bleed pattern with a digital inkjet printing machine;

[0028] D, after drying the green body 2 obtained in step C, put it into a kiln ...

Embodiment 1

[0040] A kind of preparation method of oozing flower porcelain brick:

[0041] A. If figure 1 As shown, the powder is laid in the mold cavity of the lower die 11 of the stamping die 1, and the green body 2 with the structure of the surrounding ring 21 is obtained by stamping and pressing by the upper die 12. The stamping surface of the upper die 12 is provided with a boss , the area of the boss is smaller than the cloth area of the die cavity of the lower mold 11, the surrounding ring 21 surrounds the surface of the green body 2 to form a cloth chamber 22, and the height of the cloth chamber 22 is 3 mm. The green body 2 is spare;

[0042]B. After drying the green body 2 obtained in step A, evenly distribute flour paste in the cloth cavity 22 thereof, the ball milling fineness of the flour paste is 0.9% remaining on a 250 mesh sieve to form a decorative layer 3;

[0043] C. Print the water-soluble bleed ink on the surface of the batter body 2 according to the designed ble...

Embodiment 2

[0047] A method for preparing a bleed-through porcelain brick with a splicing effect:

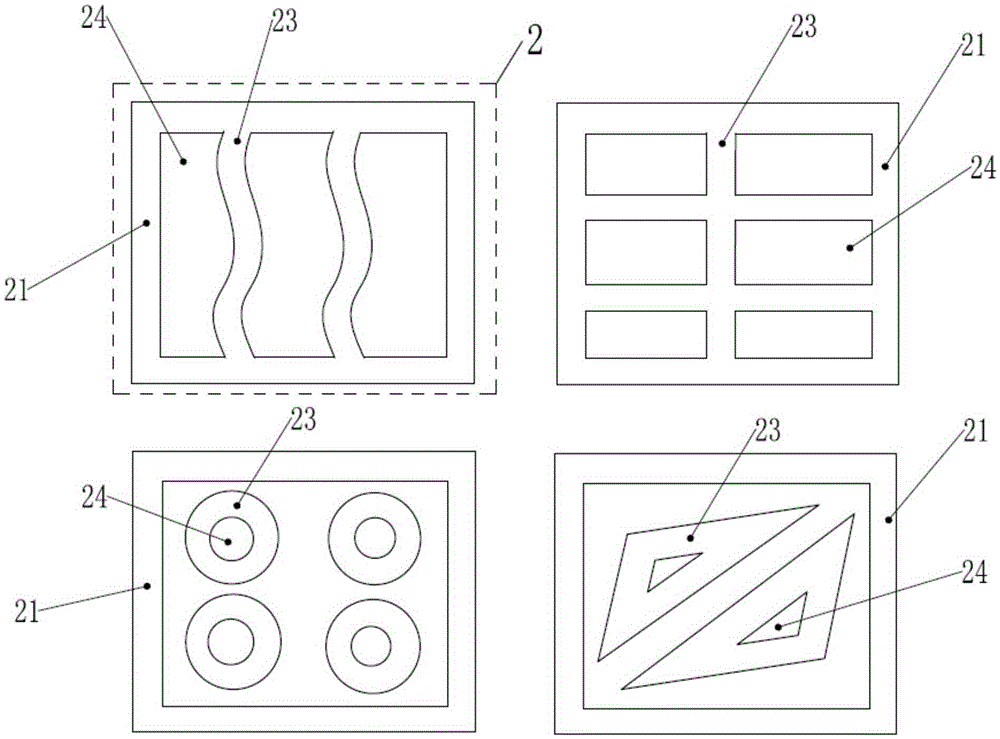

[0048] A. If figure 1 As shown, the powder is laid in the mold cavity of the lower die 11 of the stamping die 1, and the green body 2 with the structure of the surrounding ring 21 is obtained by stamping and pressing by the upper die 12. The stamping surface of the upper die 12 is provided with a boss , the area of the boss is smaller than the cloth area of the die cavity of the lower mold 11, the surrounding ring 21 surrounds the surface of the blank 2 to form a cloth chamber 22, and the cloth chamber 22 is formed by a boundary protrusion 23 The cloth sub-cavities 24 are spaced into wavy shapes, the height of the boundary protrusion 23 is consistent with the height of the surrounding ring 21, the height of the cloth chamber 22 is 3mm, and the transfer body 2 is used for standby;

[0049] B. After drying the green body 2 obtained in step A, evenly distribute flour paste in the cloth ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com