L-arginine alpha-ketoisocaproate preparation method

A technology of ketoisocaproic acid and isocaproate, which is applied in the field of preparation of L-arginine a-ketoisocaproate, can solve the problems of high total cost, inability to apply solvents, and high requirements for solvents and reaction systems. achieve good looseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific operation examples:

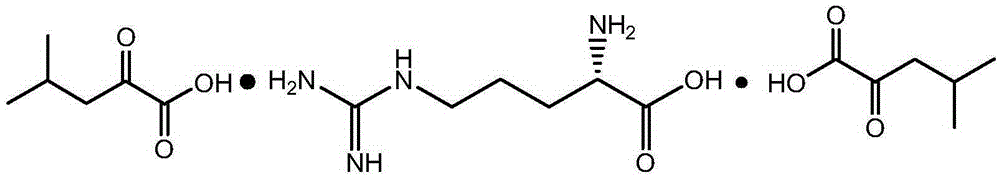

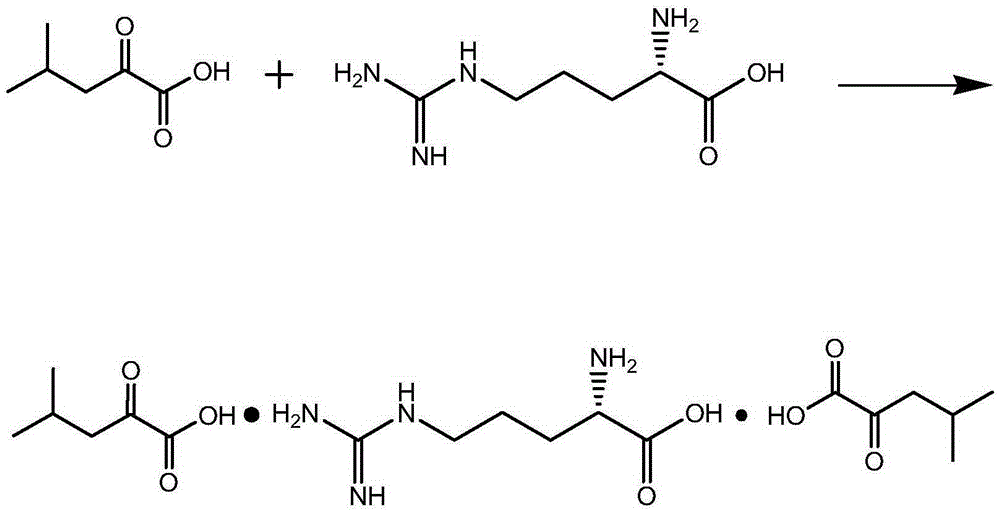

[0015] Reaction equation:

[0016]

[0017]

[0018] Equipment: Mechanical Stirrer S312-90

[0019] High Speed Centrifugal Spray Dryer RY-LGP-5

[0020] Operation process:

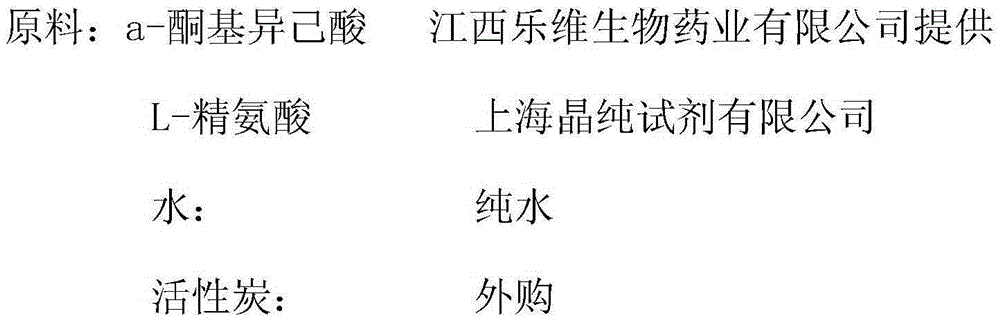

[0021] Accurately weigh 100 grams of a-ketoisocaproic acid, put it into a 1000ml three-necked flask, add 600ml of water, heat to 60-70°C, then slowly add L-arginine in portions to adjust the solution system to neutral Finally, add 10 grams of activated carbon, stir at 60-70° C. for 1 hour, filter while hot, and collect the filtrate.

[0022] Turn on the heating of the high-speed centrifugal spray dryer in advance, set the air inlet temperature at 130-135°C, and when the temperature is constant, add the filtrate prepared earlier into the solution tank, and control the flow rate of the feed pump at 5-10ml / min, so that after The material after centrifugal spray drying is collected in granular form at the discharge port. 160 g of L-arginine a-ketoisocaproate w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com