A kind of electroless pc/abs alloy material suitable for two-color injection molding and its preparation method

A two-color injection molding, alloy material technology, applied in the field of polymer materials, can solve problems such as poor fluidity, stress cracking, fracture, etc., and achieve good application prospects, improve the degree of reaction, and improve the effect of reaction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

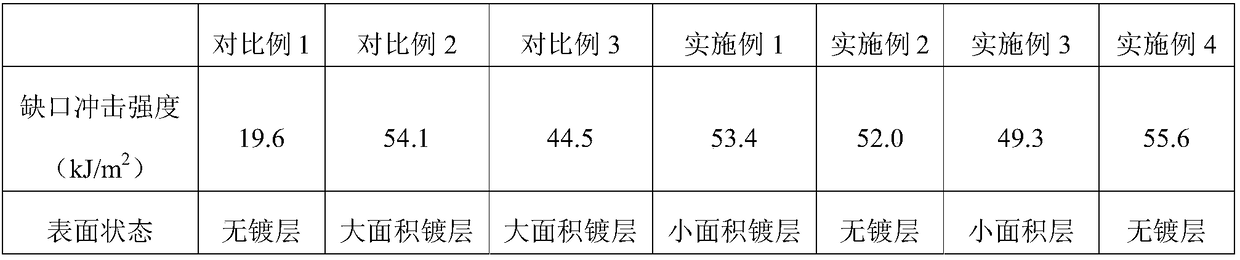

Examples

Embodiment 1

[0045] The present embodiment is applicable to the electroless PC / ABS alloy material of two-color injection molding and preparation method thereof, and this method comprises the following steps:

[0046] (1) Weigh each component by weight: PC resin: 35 parts, ABS high rubber powder: 40 parts; compatibilizer: 25 parts; initiator: 0.1 part; antioxidant 1076: 0.1 part, antioxidant 168: 0.1 part, lubricant PETS: 0.1 part.

[0047] (2) Feed the raw materials from the feeding port, melt and extrude at 200-270°C, the diameter of the screw extruder is 35mm, the aspect ratio is 32, the rotation speed is 500rpm, and the pressure is 2MPa. After melt extrusion, the obtained High rubber powder masterbatch.

[0048] (3) Weigh each component by weight: PC resin: 55 parts, high rubber powder masterbatch: 30 parts, SAN resin: 15 parts; antioxidant 1076: 0.1 part, antioxidant 168: 0.1 part, lubrication Agent PETS: 0.1 parts.

[0049] (4) Feed the raw materials from the feeding port, melt and e...

Embodiment 2

[0052] An electroless PC / ABS alloy material suitable for two-color injection molding and a preparation method thereof, the method comprising the following steps:

[0053] (1) Weigh each component by weight: PC resin: 35 parts, ABS high rubber powder: 40 parts; compatibilizer: 25 parts; initiator: 0.5 part; antioxidant 1076: 0.1 part, antioxidant 168: 0.1 part, lubricant PETS: 0.1 part.

[0054] (2) Feed the raw materials from the feeding port, melt and extrude at 200-270°C, the diameter of the screw extruder is 58mm, the aspect ratio is 60, the rotation speed is 500rpm, and the pressure is 2MPa. After melt extrusion, the obtained High rubber powder masterbatch.

[0055] (3) Weigh each component by weight: PC resin: 55 parts, high rubber powder masterbatch: 30 parts, SAN resin: 15 parts; antioxidant 1076: 0.1 part, antioxidant 168: 0.1 part, lubrication Agent PETS: 0.1 parts.

[0056] (4) Feed the raw materials from the feeding port, melt and extrude at 200-270°C, the diamet...

Embodiment 3

[0059] The present embodiment is applicable to the electroless PC / ABS alloy material of two-color injection molding and preparation method thereof, and this method comprises the following steps:

[0060] (1) Weigh each component by weight: PC resin: 35 parts, ABS high rubber powder: 40 parts; compatibilizer: 25 parts; antioxidant 1076: 0.1 part, antioxidant 168: 0.1 part, lubricating Agent PETS: 0.1 parts.

[0061] (2) Feed the raw materials from the feeding port, melt and extrude at 200-270°C, the diameter of the screw extruder is 58mm, the aspect ratio is 60, the rotation speed is 500rpm, and the pressure is 2MPa. After melt extrusion, the obtained High rubber powder masterbatch.

[0062] (3) Weigh each component by weight: PC resin: 60 parts, high rubber powder masterbatch: 25 parts, SAN resin: 15 parts; antioxidant 1076: 0.1 part, antioxidant 168: 0.1 part, lubrication Agent PETS: 0.1 parts.

[0063] (4) Feed the raw materials from the feeding port, melt and extrude at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com