A thermal cracking device for Fischer-Tropsch synthesis reaction wax slag and its application method

A technology of Fischer-Tropsch synthesis and thermal cracking, which is applied in special forms of dry distillation, coke oven, petroleum industry, etc., can solve the problems of equipment service life impact, unstable operating conditions, and high equipment maintenance rate, so as to reduce workload and reduce Dust content, improve the effect of heat utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

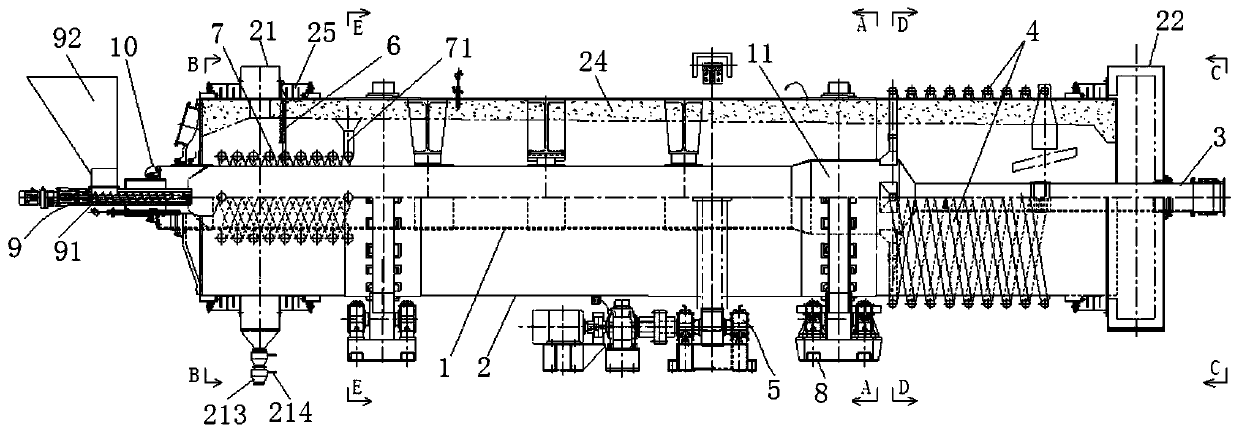

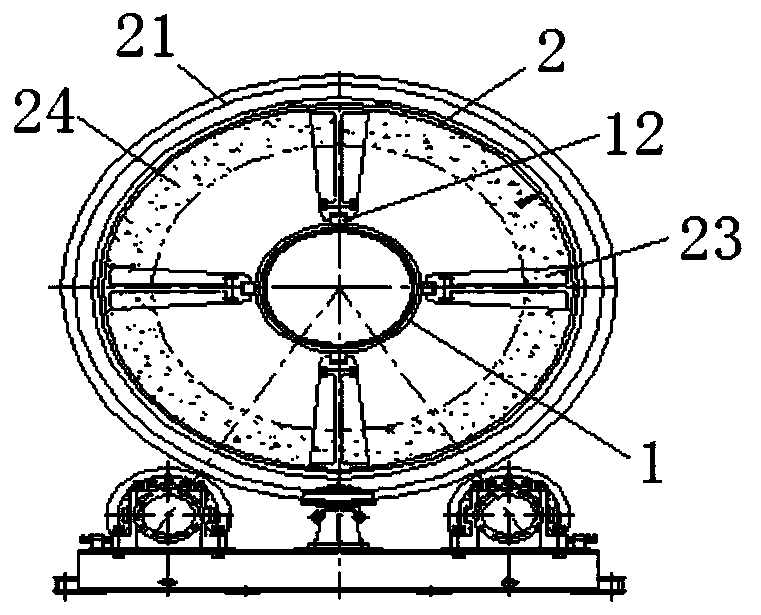

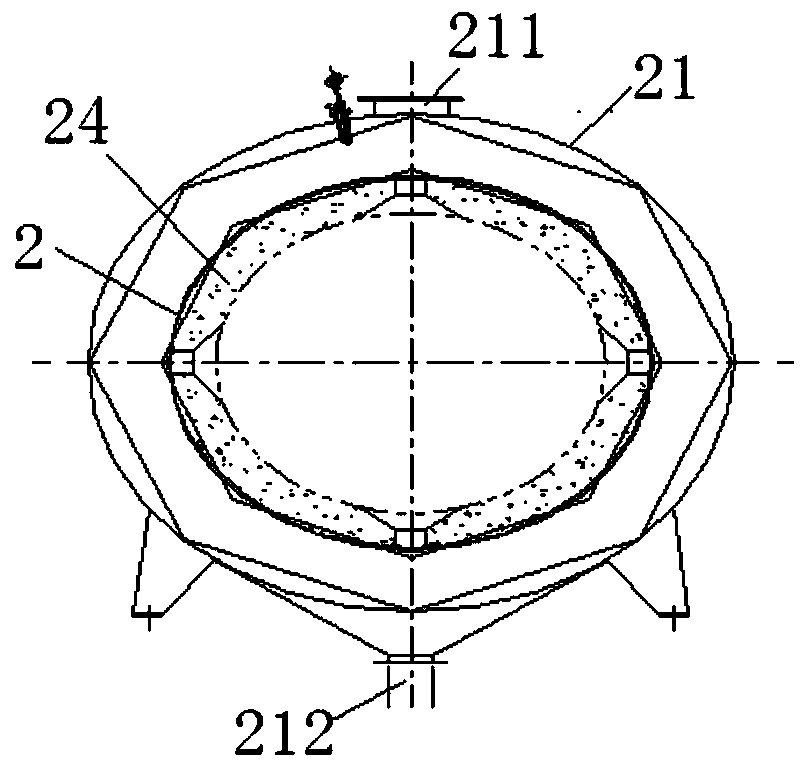

[0022] Such as Figure 1~6 As shown, the thermal cracking device for Fischer-Tropsch synthesis reaction wax slag proposed by the present invention includes a rotary kiln with an inner cylinder 1 and an outer cylinder 2 , and the outer cylinder 2 is sleeved outside the inner cylinder 1 . The beginning of the inner cylinder 1 is the feed end, the end of the inner cylinder 1 is the outlet end and is connected to the beginning of the oil and gas outlet pipe 3 , and the end of the oil and gas outlet pipe 3 extends out of the end of the outer cylinder 2 . The inner wall of the inner cylinder 1 is provided with a spiral blade, which is used to push the raw material wax slag to move from the feed end of the inner cylinder 1 to the outlet end while cracking to generate oil and gas during the rotation of the inner cylinder 1 . The outlet end of the inner cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com