A kind of processing method of phenol tar

A processing method and technology of phenol tar, applied in the petroleum industry, processing hydrocarbon oil, hydrocarbon distillation and other directions, can solve the problems of waste and difficult recovery of phenol products, and achieve the effects of reducing dosage, reducing emissions and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

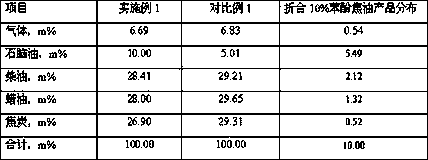

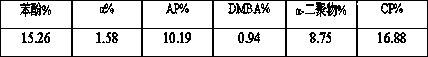

[0016] The raw material is phenol tar selected from a refinery, and the specific properties are shown in Table 1. The feedstock for conventional coking is the vacuum residue of a refinery, and the outlet temperature of the heating furnace is 500°C. When the coke filling amount of the coke tower with the vacuum residue reaches 90% of the maximum safe coke filling height, stop the coke tower with the vacuum residue Coke charging, switch to 250°C phenol tar and continue to charge the coke tower through the steam purge pipeline of the coke tower. The amount of material is 10%, and the steam blowing time is 3.5h. The specific product distribution is shown in Table 2.

Embodiment 2

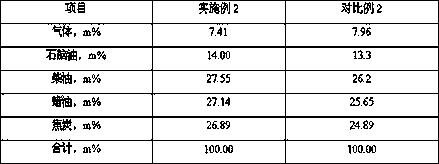

[0020] The outlet temperature of the conventional coking feed heating furnace is 510 ° C. When the coke filling amount of the coke tower with vacuum residue oil reaches the maximum safe coke filling height of 95%, stop the coke filling of the coke tower with vacuum residue oil and switch to phenol at 280 ° C. The tar continues to fill the coke tower through the steam purge pipeline of the coke tower. When the temperature in the coke tower is lower than 420°C, the phenol tar charging process is stopped. The final phenol tar accounts for 20% of the total coking feed, and the water vapor is small. The blowing time is 1h, and the big blowing time is 3h. The specific product distribution is shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com