Installing process of offshore water taking head caisson of power plant

An installation process and water intake technology, applied in caisson, water supply device, drinking water device and other directions, can solve the problems of heavy water outlet, unable to float, difficult to control balance, etc., to improve project quality, shorten construction period and reduce engineering The effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

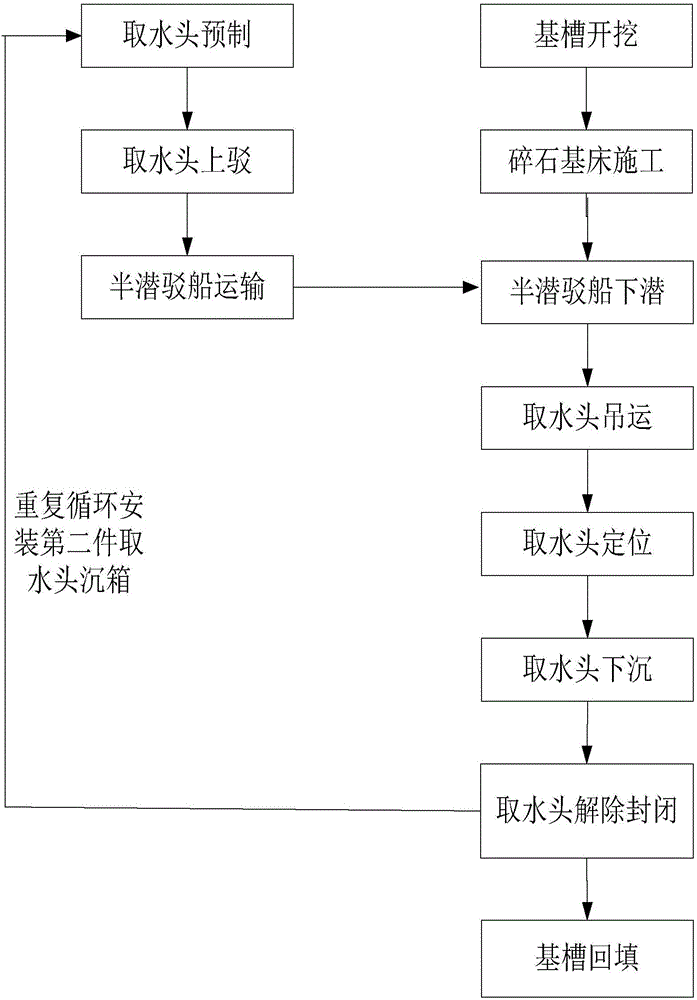

[0030] see Figure 1 to Figure 6 , the installation process of the sea water intake head caisson of the power plant of the present invention, comprises the following steps: water intake head prefabrication, water intake head barge, semi-submerged barge transportation, semi-submersible barge submersion, water intake head hoisting, water intake head positioning, water intake head sinking Installation and unblocking of the water head.

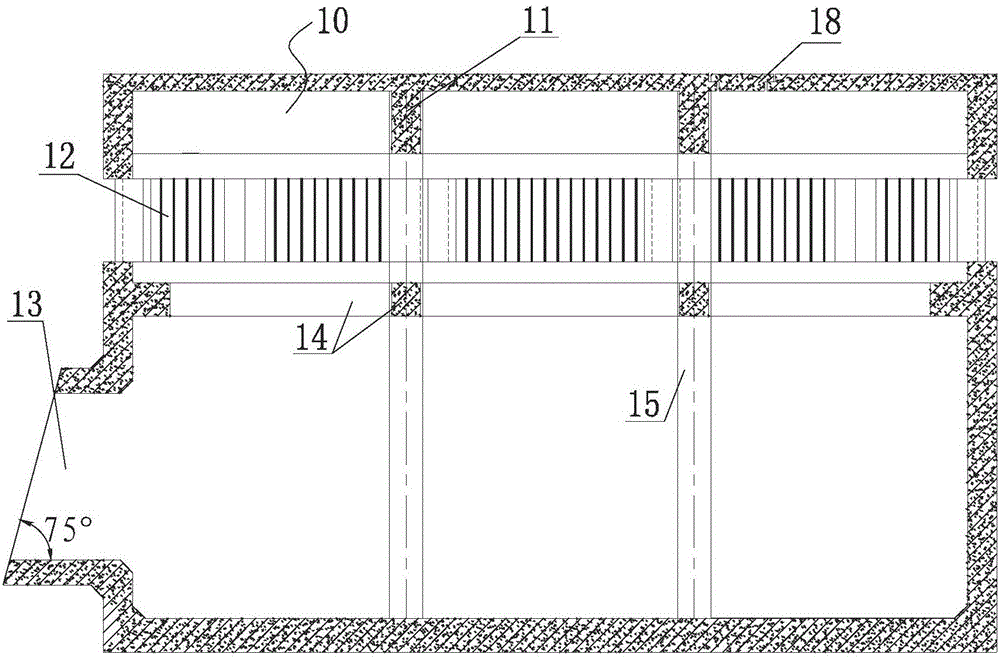

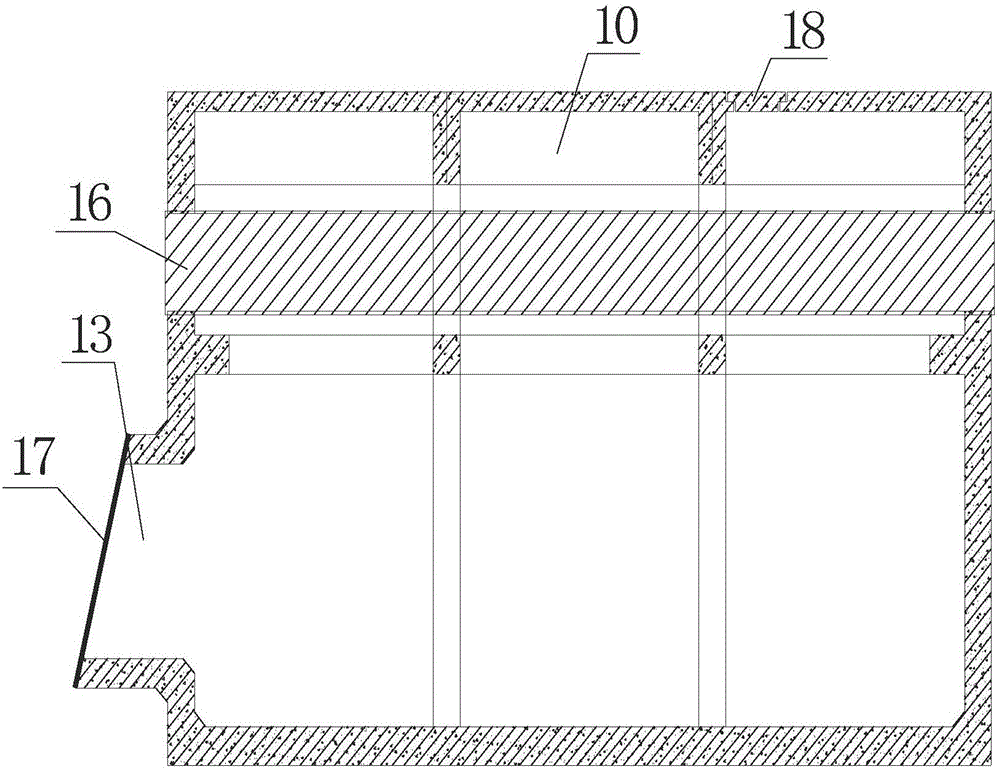

[0031] When carrying out the prefabrication step of the water intake head, two water intake caissons are prefabricated at the prefabrication yard wharf; each water intake caisson 10 is cylindrical with a top plate and a bottom plate and has an outer diameter of 21.4m, a height of 13.85m, and a wall thickness of 0.7m. m, with a weight of 2800t; 2.5m below the top surface of the water intake caisson 10, there is a circular water inlet window wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com