Air reverse circulation continuous coring ice drill bit

An air reverse circulation and coring technology, which is applied in the direction of drill bits, undisturbed core extraction devices, drilling equipment, etc., can solve the problems of reducing the collection rate of ice core ice samples, difficulty in drilling into ice layers, and affecting drilling efficiency, etc. Improve the recovery rate, shorten the construction period, and improve the drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

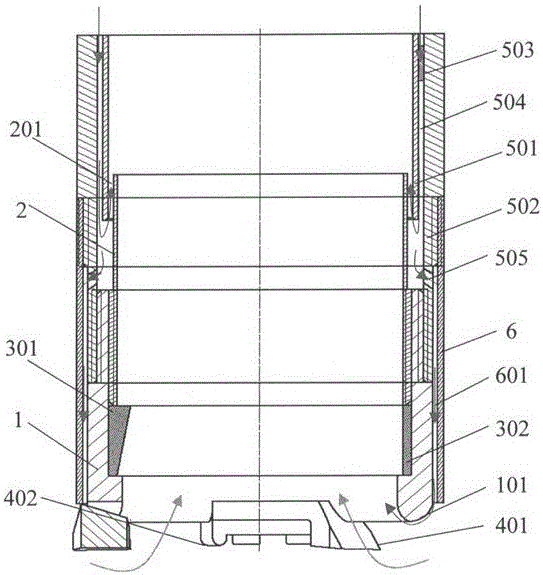

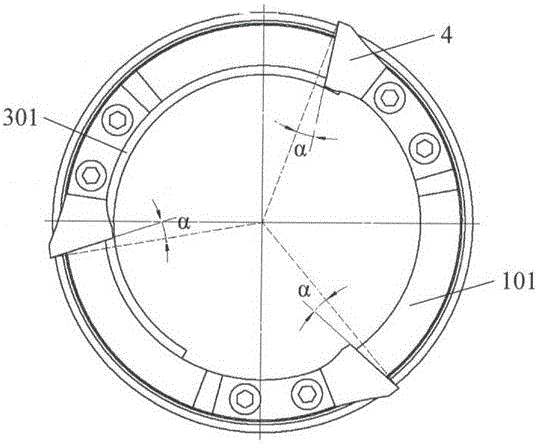

[0016] see figure 1 , figure 2 , image 3 with Figure 4 As shown, this embodiment includes a drill bit body 1, a nozzle holder 2, an ice core snap-off device 3, a cutting head 4, a double-wall joint 5, a shroud 6 and a shoe 7, and the drill bit body 1 and the double-wall joint 5 The outer pipe 502 of the double-walled joint is threaded, and the bottom lip of the drill body 1 is fixed with several cutting bits 4 by bolts. Chips migrate to the center channel. The cutting depth of the cutting bit 4 is controlled by the pad shoe 7, and the pad shoe 7 is connected with the cutting bit 4 and the drill bit body 1 by bolts. The bottom lip surface of the drill body 1 is an arc-shaped surface 101 . The nozzle pipe 2 is connected with the drill bit body 1 by threads, and the ice core snap-off device 3 is fixed on the inner step of the drill bit body 1 .

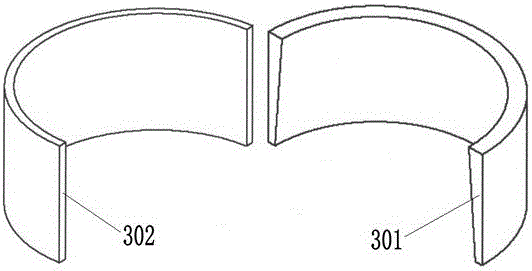

[0017] The ice core snapping device 3 is composed of a semicircular wedge structure 301 and a semicircular structure 302 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com