A semi-rotary mechanism with fixed shaft and belt drive

A technology of belt transmission and fixed shaft, which is applied in the field of bionic machinery, can solve the problems of poor motion stability and load-bearing capacity, poor motion stability and load-bearing capacity of the mechanism, and can only work in one direction, so as to improve work reliability and improve Carrying capacity, the effect of reducing centrifugal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following embodiments.

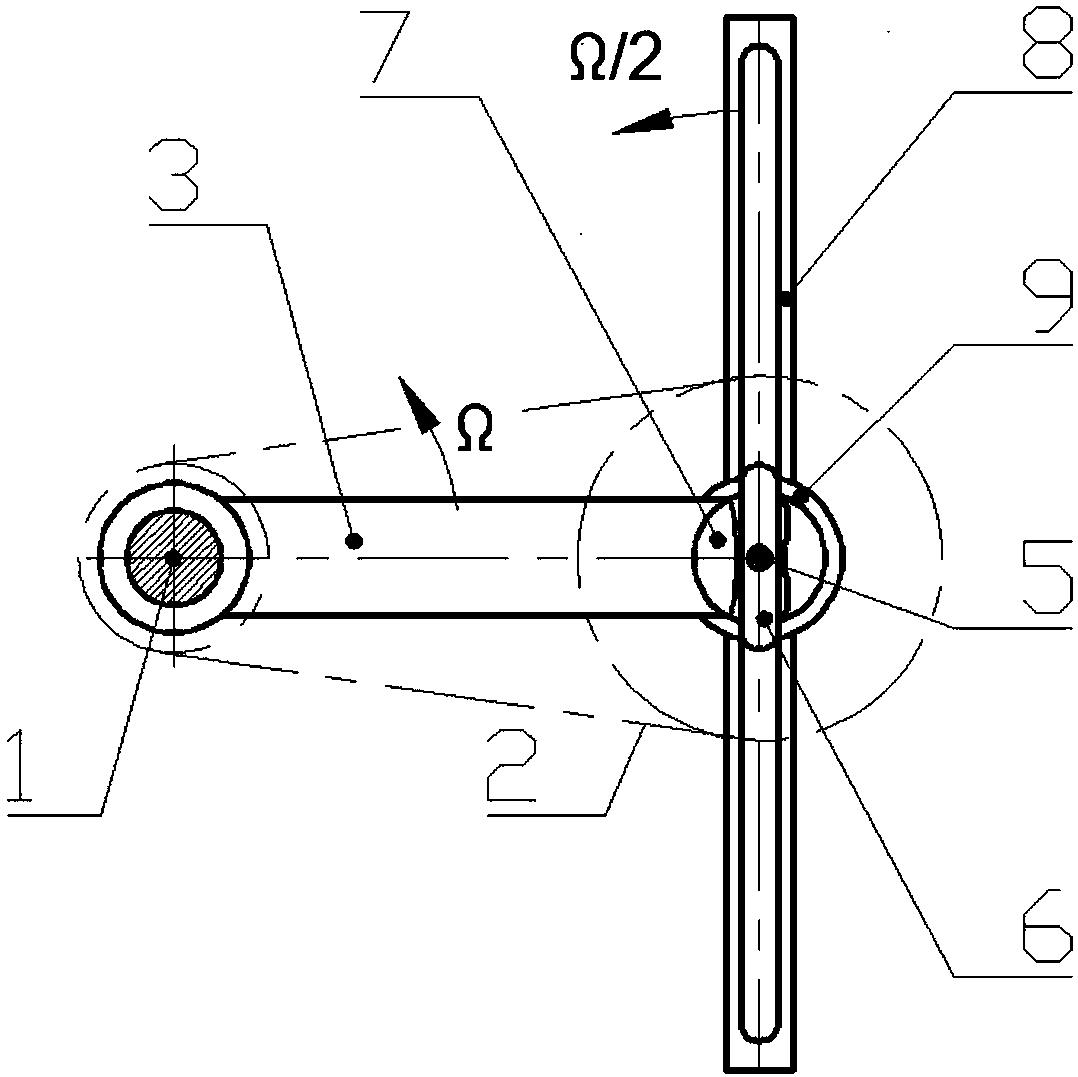

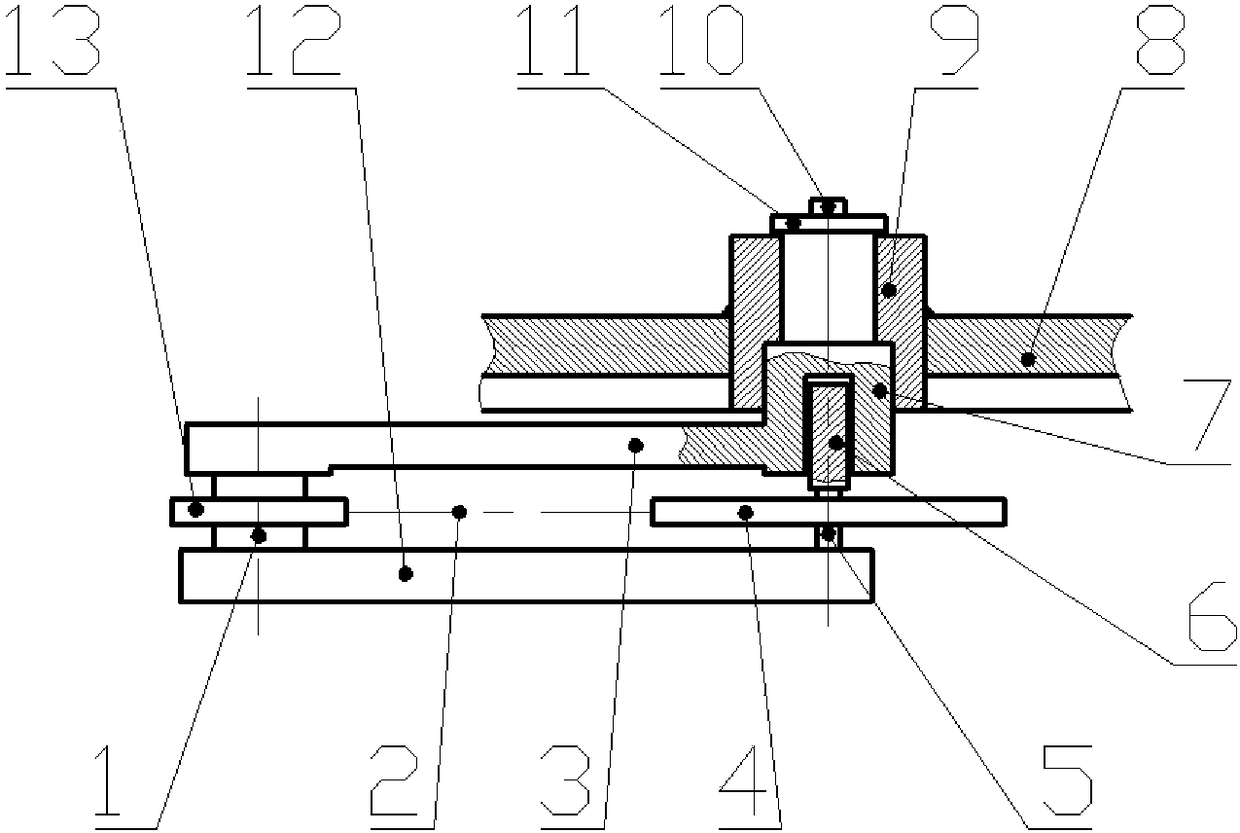

[0015] figure 1 One end of the middle crank 3 is fixedly connected with the main shaft 1, and the other end is fixedly connected with the moving shaft 7. The slide block 6 is fixedly connected with the auxiliary shaft 5, the distance from the auxiliary shaft 5 to the main shaft 1 is equal to the length of the crank 3, and the length of the slide block 6 is greater than the length of the opening groove+the thickness of the slide block 6. The middle part of the half-rotating rod 8 is fixedly connected with the axle sleeve 9, and the half-rotating rod 8 has a longitudinal chute along the axis of the rod. The length of the longitudinal chute must be greater than 4 times the length of the crank 3, and the longitudinal chute passes through The shaft sleeve 9 forms a correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com