Controllable multi-directional flow convection heat exchange flue that is resistant to dust deposition and condensation, high temperature resistance and load tracking

A convective heat transfer and load tracking technology, applied in lighting and heating equipment, combustion methods, exhaust gas devices, etc., can solve problems such as reduced bearing capacity, reduced mechanical properties, and inability to work normally at high temperatures, achieving convenient driving, The effect of ensuring normal operation and preventing excessive external temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

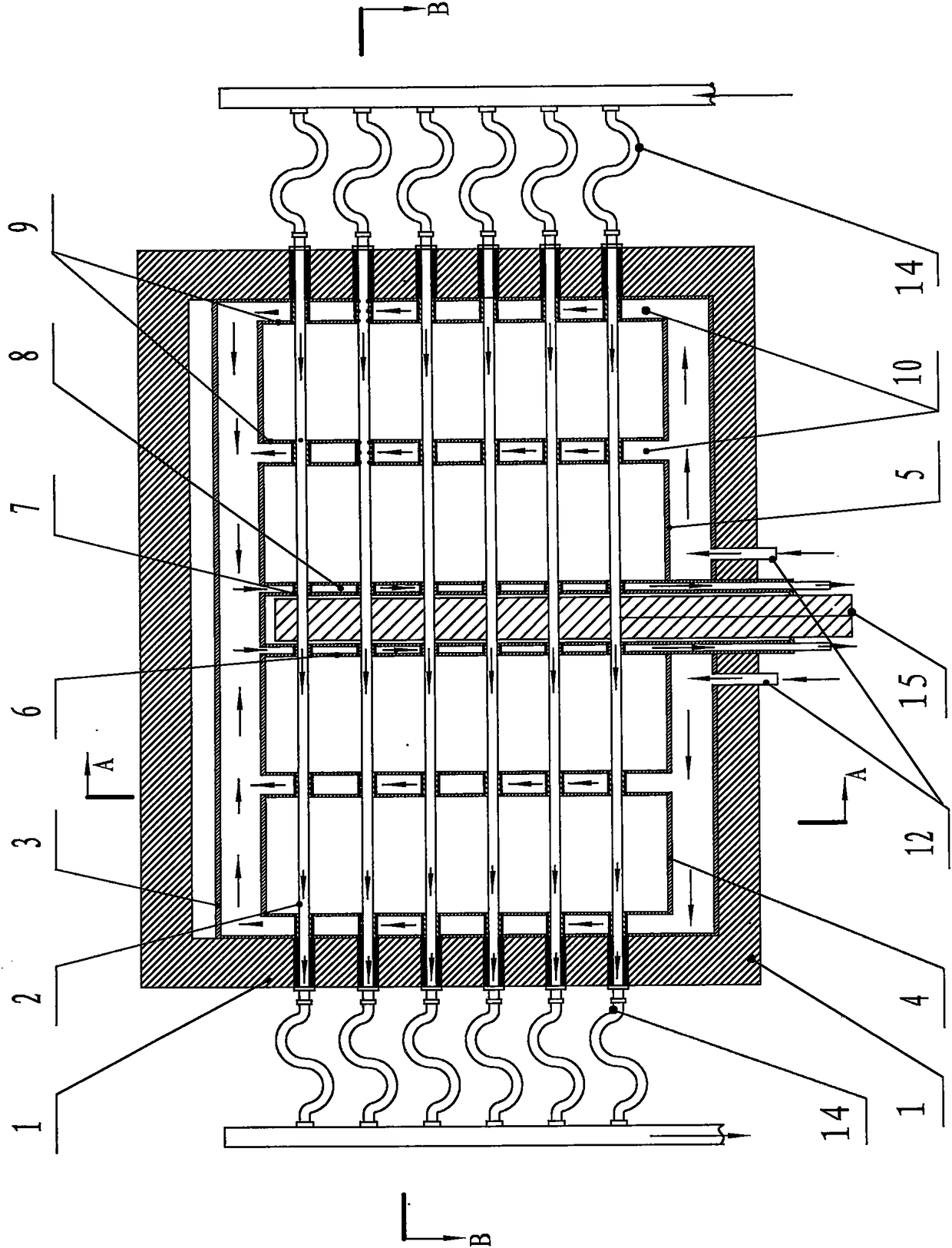

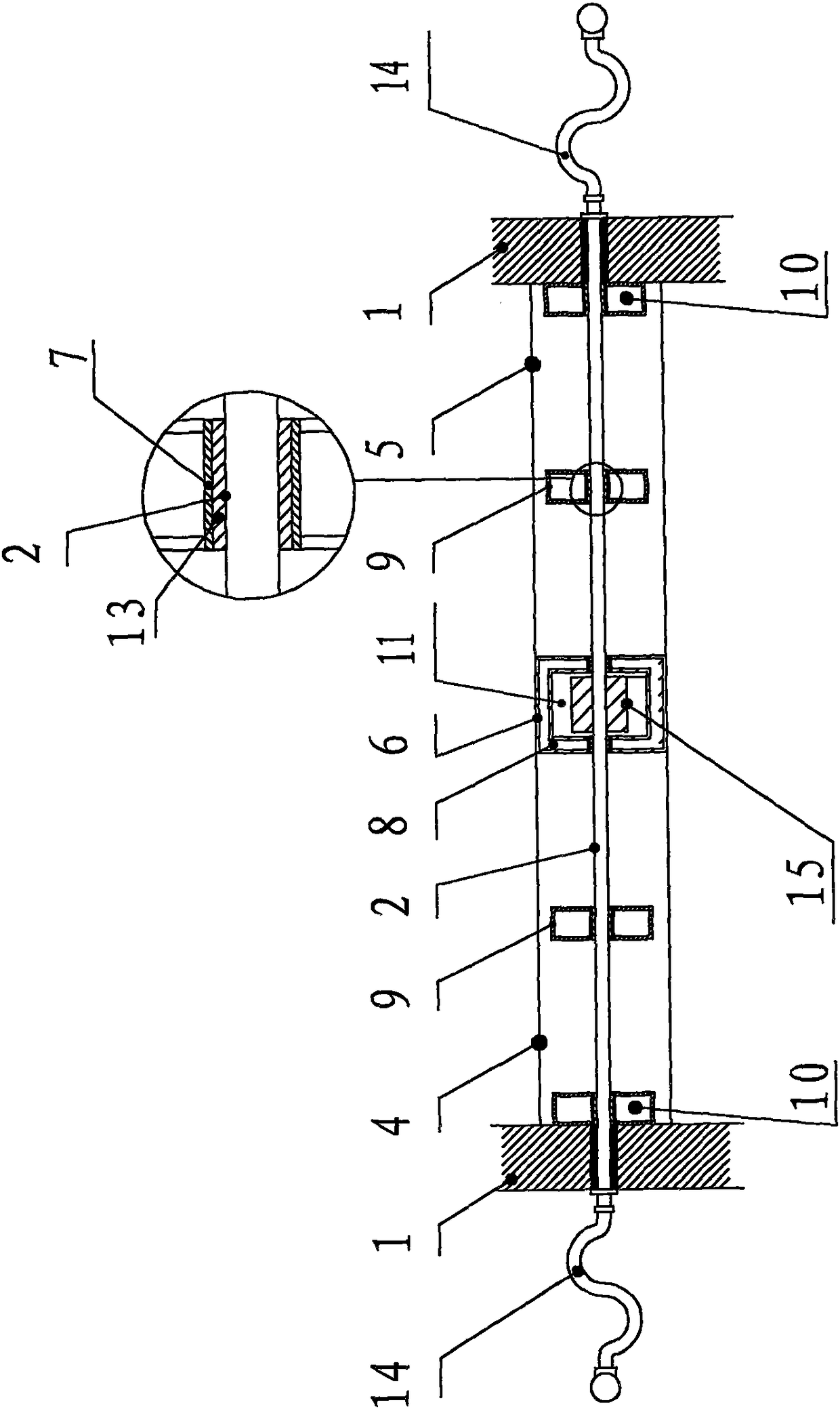

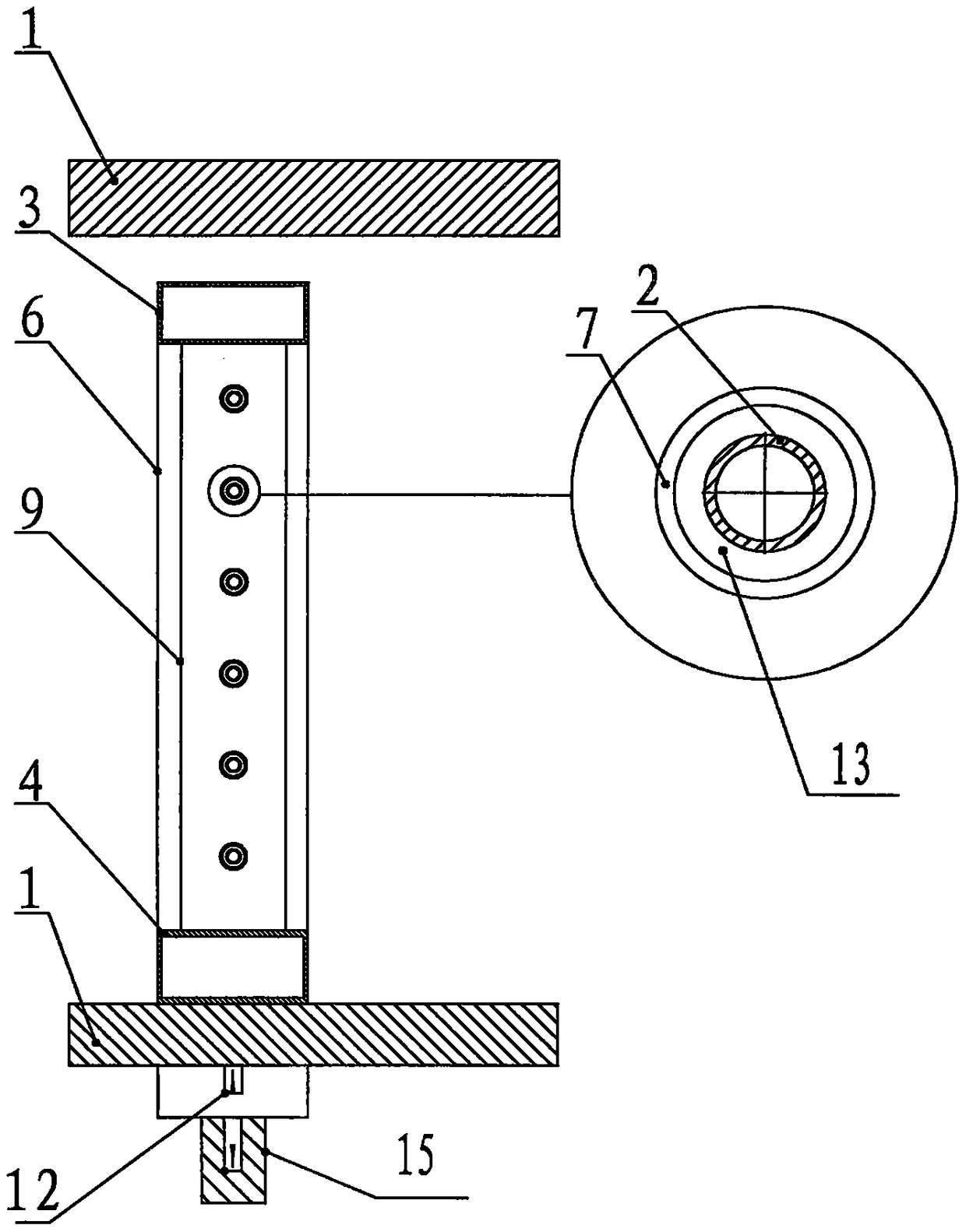

[0009] Provide preferred embodiment of the present invention below in conjunction with accompanying drawing: By figure 1 , figure 2 , image 3 The controllable multi-directional flow convection heat exchange flue that is resistant to dust deposition, condensation, high temperature and load tracking is given. It includes nine points between the adjacent convection heating surface groups and the flue gas inlet and outlet of the convection heat exchange flue. Ten-degree adjustable louvers, blade fixing frame of said louvers cooperating and fixed with the inner wall of smoke wall 1, and shaft 2 where each group of blades of said louvers are respectively connected with a transmission device capable of rotating 90 degrees.

[0010] The blade fixing frame of the shutter is a fixed frame that can be cooled by air or water cooling medium. The shaft 2 where each group of blades of the louver is located is a hollow circular shaft that can be cooled by air or water cooling medium.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com