Automatic removing and sampling method for large-diameter aggregate of concrete for rheology

A concrete, large particle size technology, applied in sampling devices, chemical instruments and methods, preparation of test samples, etc., can solve the problem of inability to meet the requirements of automatic and stable rejection, lack of automatic rejection of aggregates and reliable rejection of aggregate wrapping paste The process of the body is easy to be automatically removed, and it is convenient for the aggregate to wrap the slurry, and the stability is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

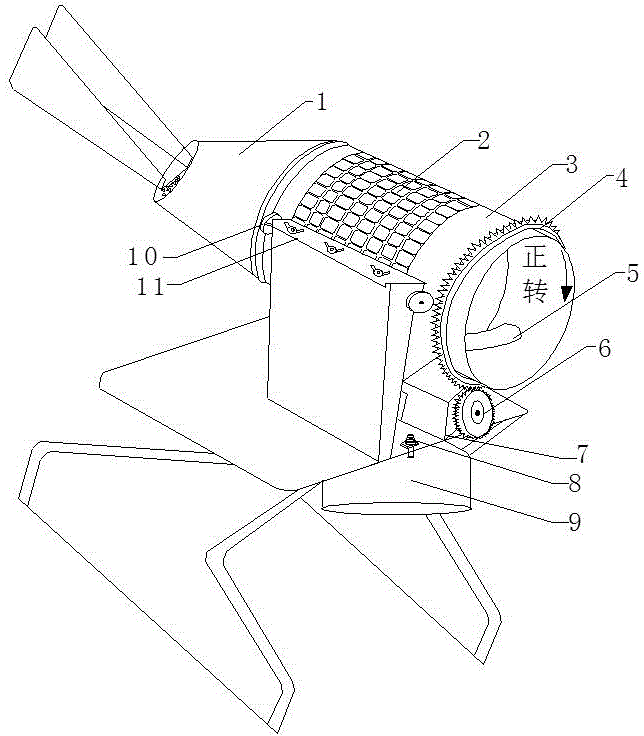

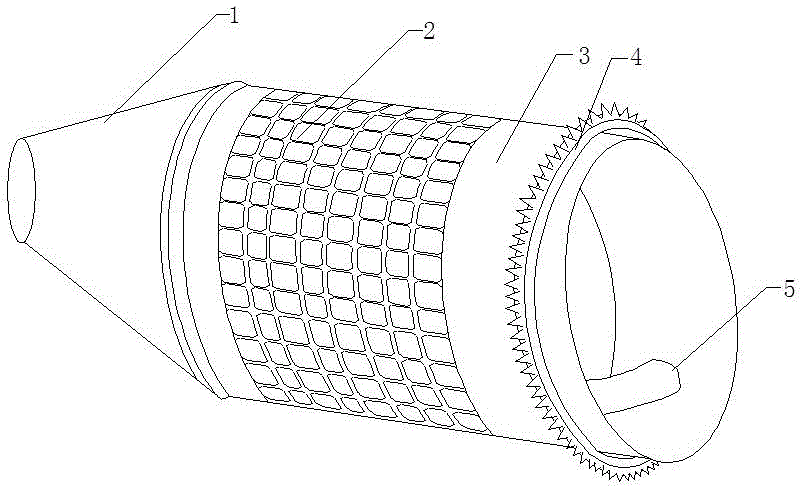

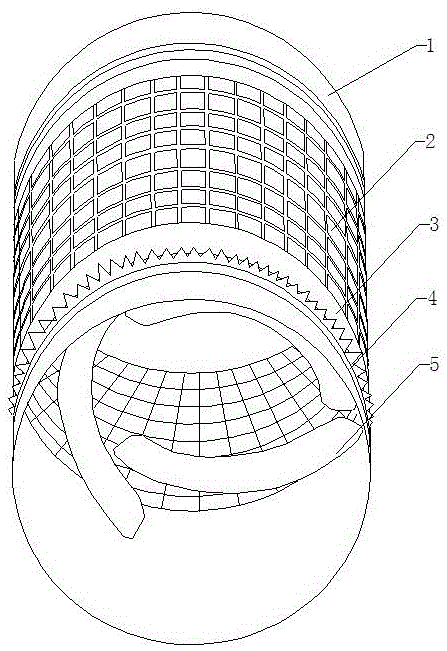

[0029] What the method implementation of the present embodiment adopts is drum type screening material system such as figure 1 As shown, the concrete rheological test sampling used to automatically remove aggregates with over-specified particle size includes an automatic material screening mechanism, a rheological test feedback mechanism and a transmission device. Its working principle is to convey the ordinary fresh concrete to the screen drum by self-flow through the guide trough, and the screen drum rotates forward to separate the coarse and fine aggregates, and the fine aggregate and slurry pass through the side length of 22 mm The square sieve hole falls into the material test capacity cylinder, and the ultrasonic material level gauge detects and feeds back the height information of the concrete sample to be tested in the material cylinder in real time. When the height reaches the test requirements, the feeding system is automatically closed, and the drum starts to revers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com