Cutter and workpiece instantaneous contact contour extraction method during five-axis side-milling machining

A technology of instantaneous contact and contour extraction, which is applied in the field of mechanical machining, can solve the problems of narrow application range and low efficiency, and achieve the effect of avoiding secondary development and taking into account calculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

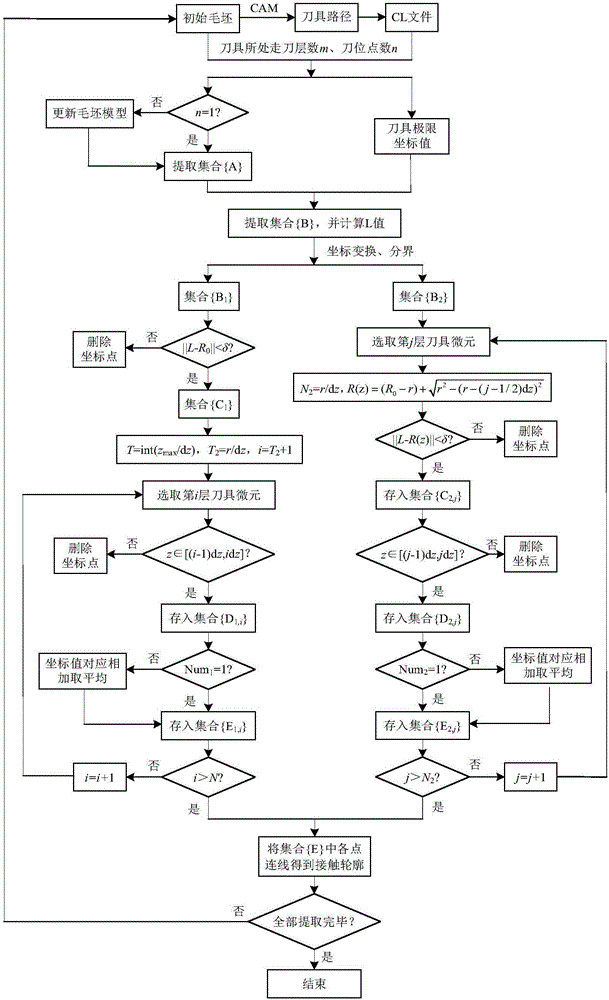

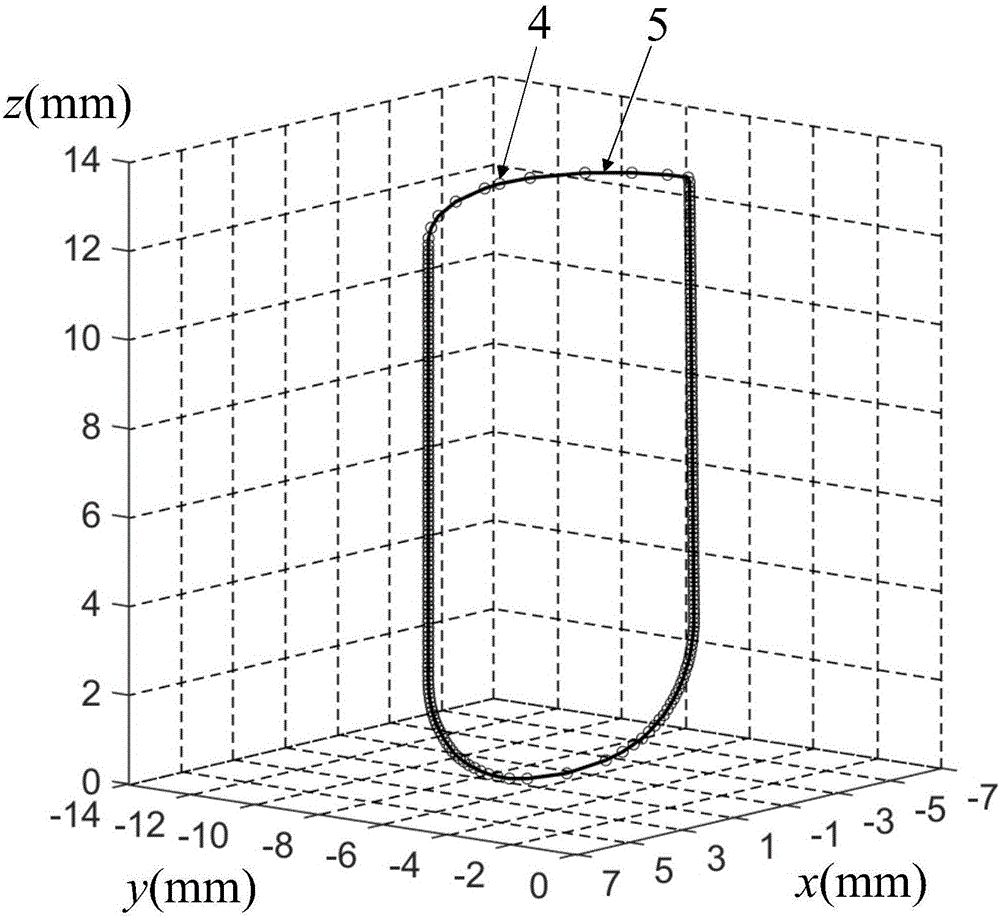

[0057] Example 1: Calculation of the instantaneous contact contour between the round nose end mill and the workpiece at the first milling layer and the 270th tool position during the side milling process of the S-shaped test piece. The calculation process is as follows figure 1 shown.

[0058] 1) The given initial condition information is as follows:

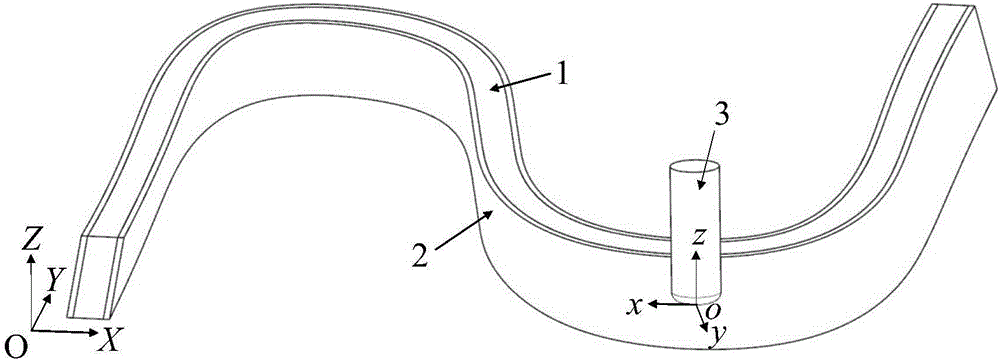

[0059] The target part processed in this embodiment is a 10 mm thick S-shaped test piece. The initial blank is obtained by symmetrically adding 2 mm thick layers to be removed on both sides of the target part. With any point on the bottom surface of the blank as the origin, the processing coordinate system O-XYZ is established. , the processing tool is a round nose end mill, and the tool radius R 0 = 8mm, tool arc radius r = 3mm, the overall height of the blank is 30mm, and it is processed in 3 layers;

[0060] The tool path of each layer of milling is automatically generated by the UG software in CAM, and the cutting position...

Embodiment 2

[0075] Example 2: Calculation of the instantaneous contact contour between the round nose end mill and the workpiece at the second milling layer and the 270th tool position during the side milling process of the S-shaped test piece. The calculation process is as follows figure 1 shown.

[0076] 1) The given initial condition information is as follows:

[0077] The target part processed in this embodiment is a 10mm thick S-shaped test piece. The initial blank is obtained by symmetrically adding 2mm thick layers to be removed on both sides of the target part. The processing coordinate system is represented by O-XYZ, and the processing tool is a round nose milling cutter. , tool radius R 0 = 8mm, tool arc radius r = 3mm, the overall height of the blank is 30mm, and it is processed in 3 layers;

[0078] The tool path of each layer of milling is automatically generated by the UG software in CAM, and the cutting position file including the position of the tool nose point, the tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com