Hydraulic pump unit and method of assembling a hydraulic pump unit

A hydraulic pump, hydraulic technology, applied in the direction of pump components, components of pumping devices for elastic fluid, fluid pressure actuators, etc., can solve problems such as drilling failures, operation failures, etc., to achieve easy handling and reduce complexity permanent, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

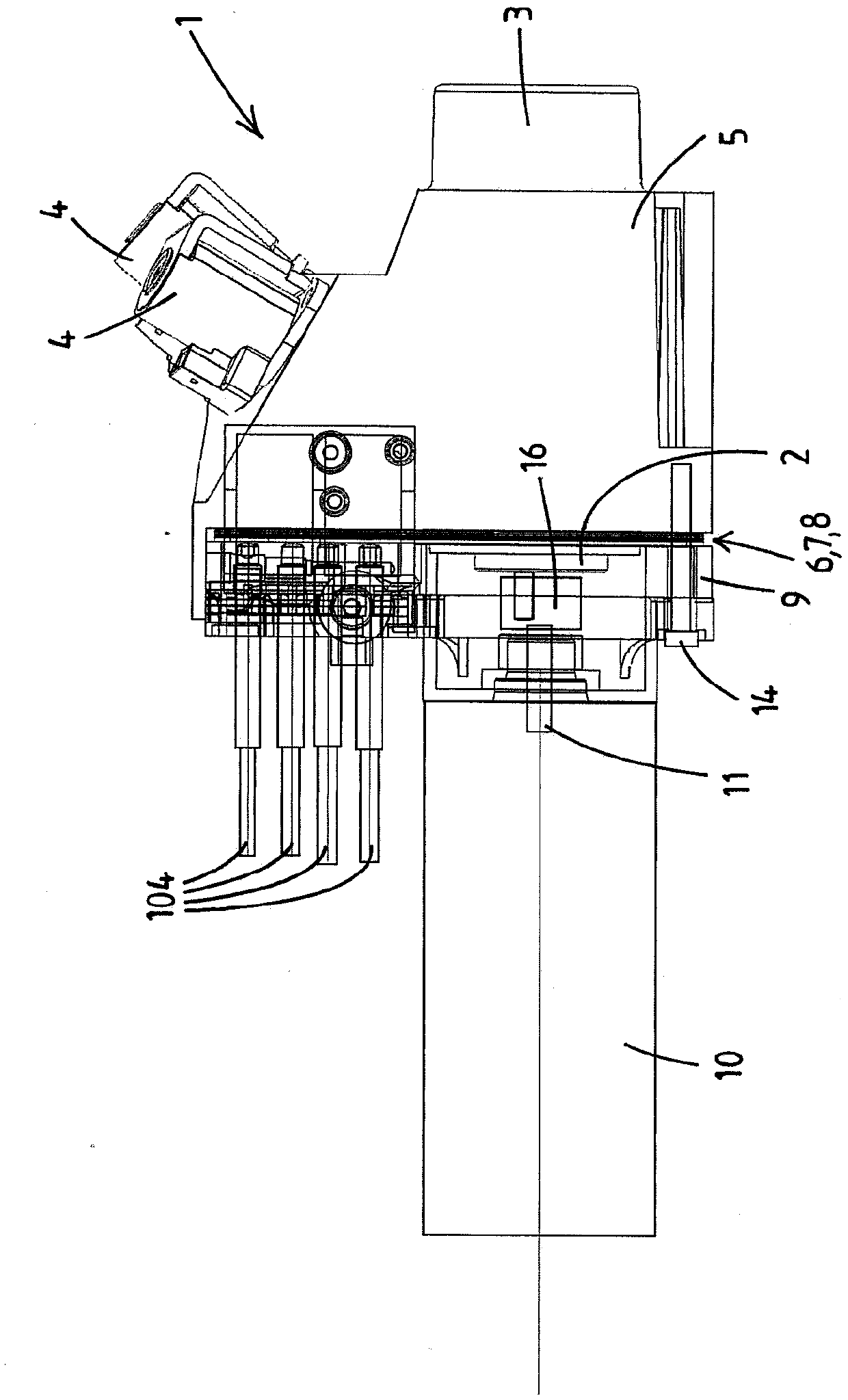

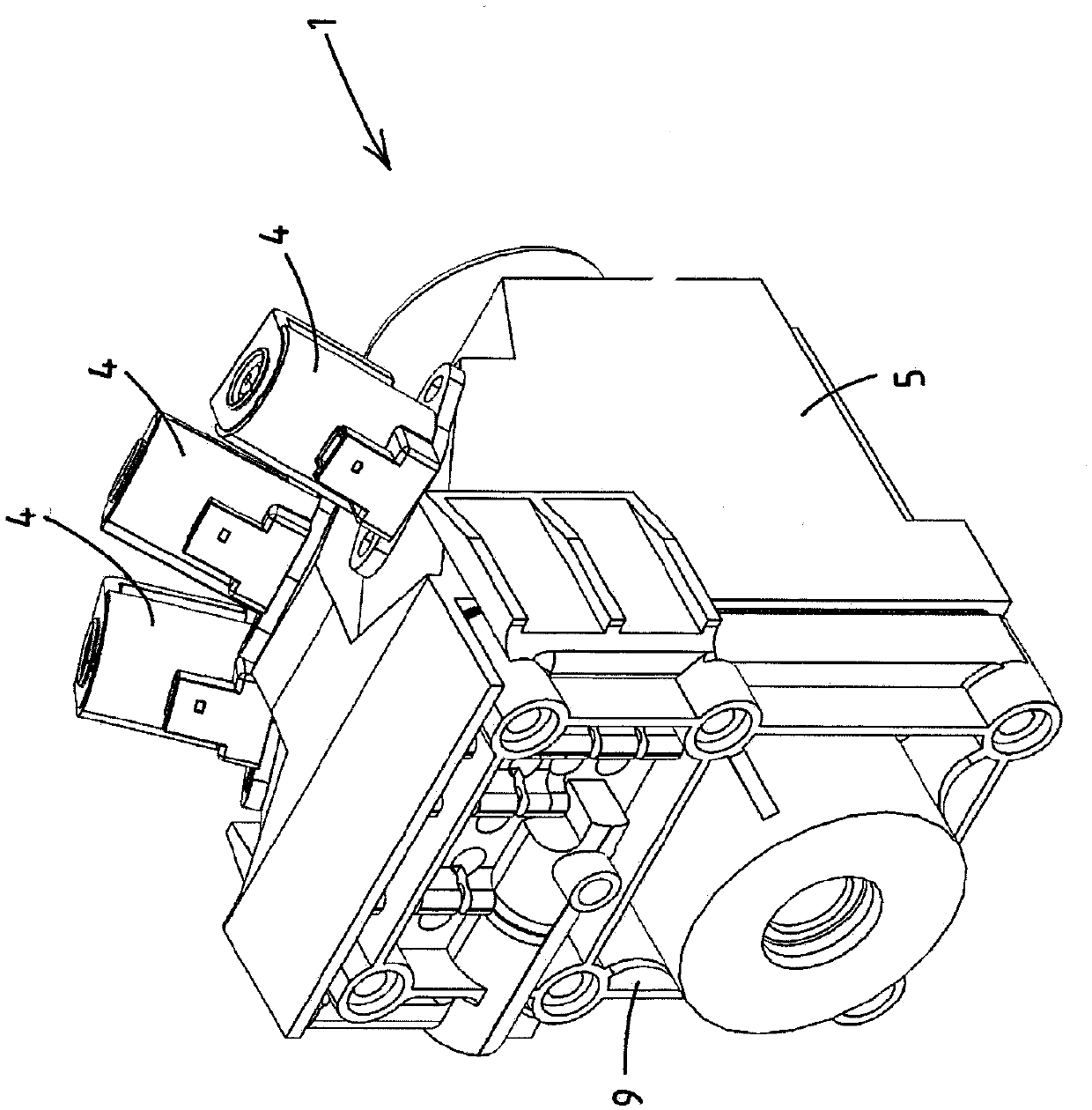

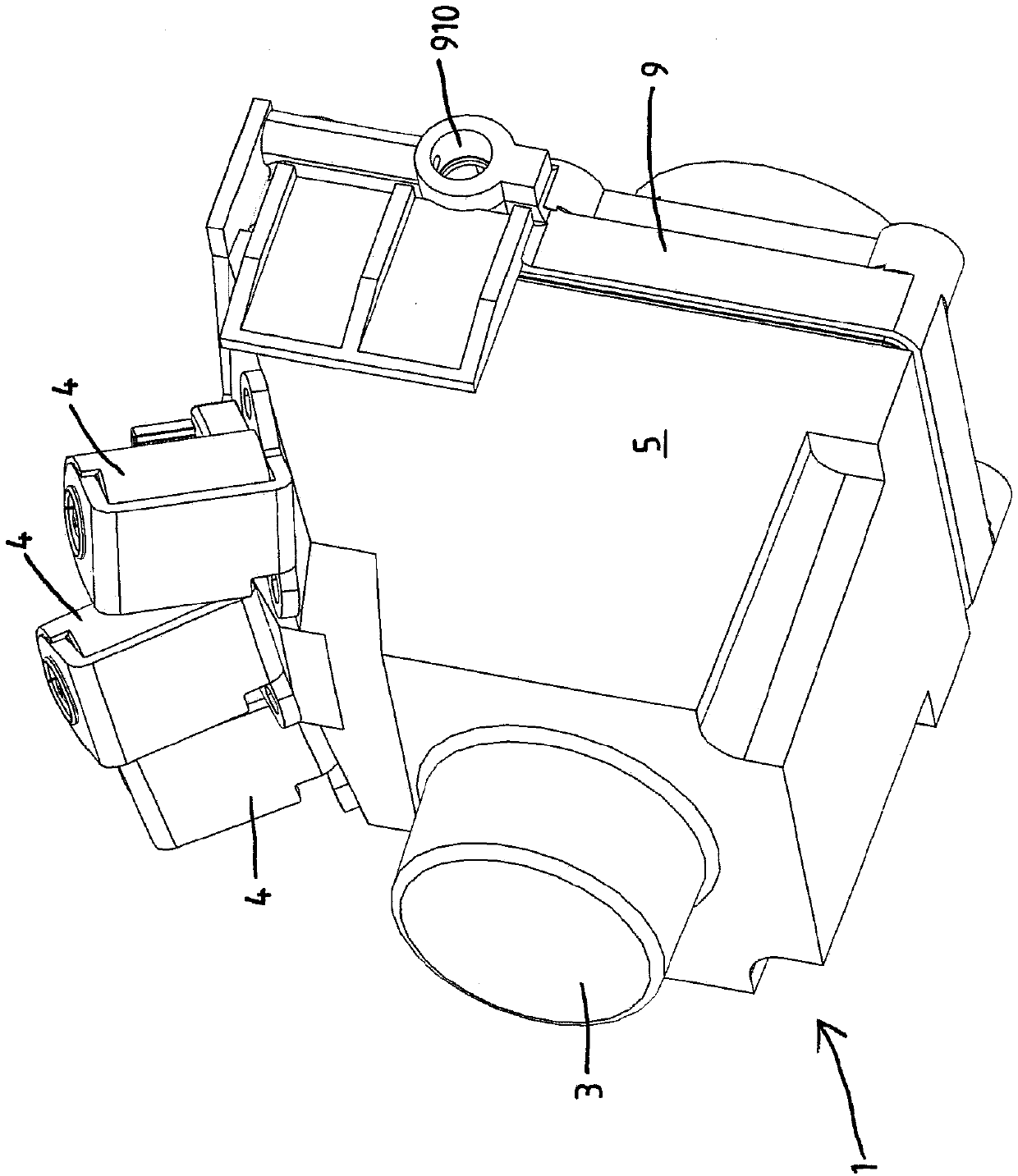

[0161] The hydraulic pump unit 1 is configured for supplying pressurized hydraulic fluid to a set of hydraulic actuators at a pressure of eg several tens of bar or even over 100 bar.

[0162] see Figure 26 , 27 , the set of hydraulic actuators includes a plurality of actuators, wherein a first actuator can be arranged to move independently of a second actuator, for example one actuator operates one element of a convertible roof system, the other An actuator operates another element of the system. The actuators herein may also be a pair of parallel actuators operating synchronously. For example, a first actuator can move with a different stroke or speed than a second actuator at the same moment.

[0163] The hydraulic pump unit 1 comprises a main body 5, a rotary drive shaft operated pump 2, a drive motor 10 and a reservoir 3 for hydraulic fluid. The end body 9 is provided with a plurality of line connectors 99 for connecting the actuator line 104 to the unit 1, such as a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com