Heat exchanger

A technology for heat exchangers and radiators, applied in heat exchange equipment, indirect heat exchangers, heat exchanger types, etc., to solve problems such as large bending stiffness, excessive use of materials, and material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

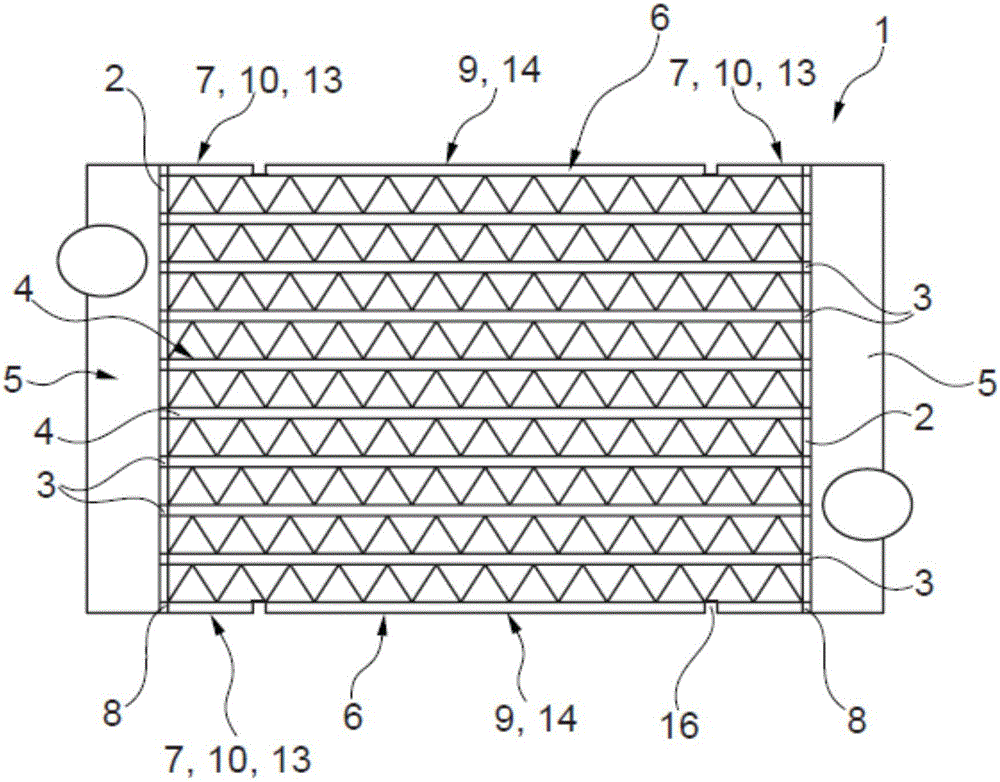

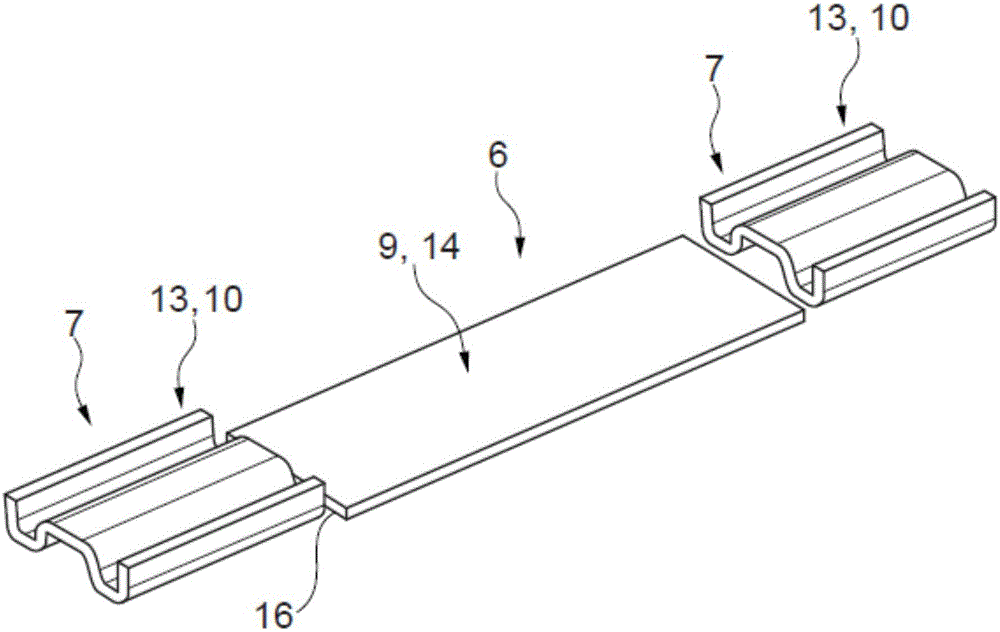

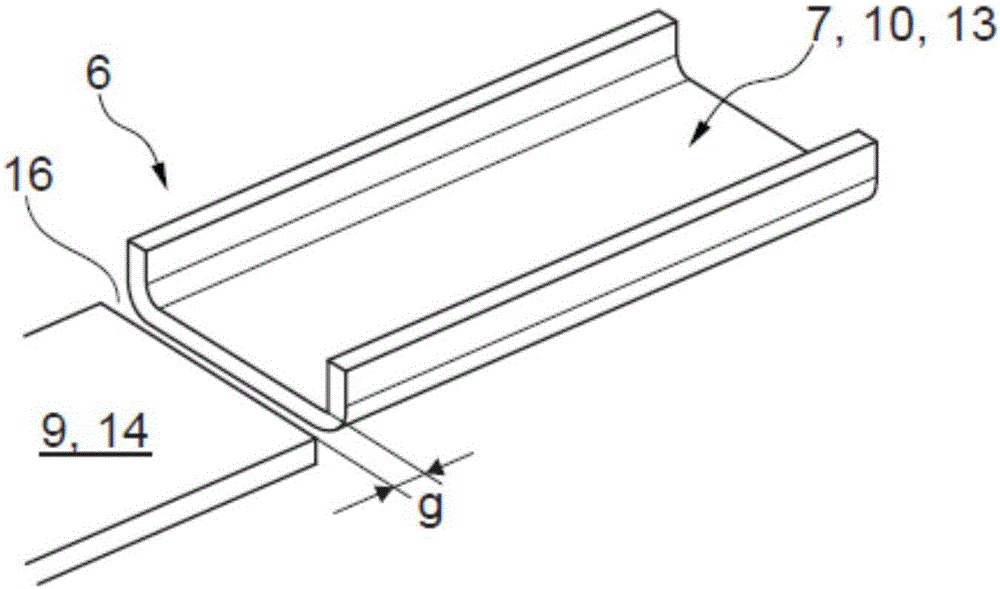

[0021] according to figure 1 A heat exchanger 1 according to the invention, which can be realized, for example, as an intercooler, comprises two floor plates 2 each having a channel 3 , for example for receiving the longitudinal end regions of fluid-conducting tubes 4 , flat tubes. The floor 2 is connected to a plenum 5 to form a collector, eg for coolant. The respective longitudinal end regions 7 of the two side parts 6 are accommodated at least partially in a channel 8 at the end of the associated floor 2 , wherein the channel 8 is likewise formed at the end by the channel 3 provided for the pipe 4 . The side pieces 6 can pass partially or all the way through the channel 8 , but do not have to. Alternatively, of course, they can also be joined to the floor 2 in some other way, for example by soldering, welding or the like.

[0022] Now, in order to be able to produce a side part 6 which not only meets the more demanding bending stiffness requirements present in the longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com