Crystal melting device for honey

A honey and pipeline technology, applied in the field of honey product processing and production equipment, can solve the problems of long melting crystallization time, low heat transfer efficiency, increasing the heating power of the heating device, etc., to shorten the melting crystallization time, high degree of intelligence, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with specific embodiments and drawings.

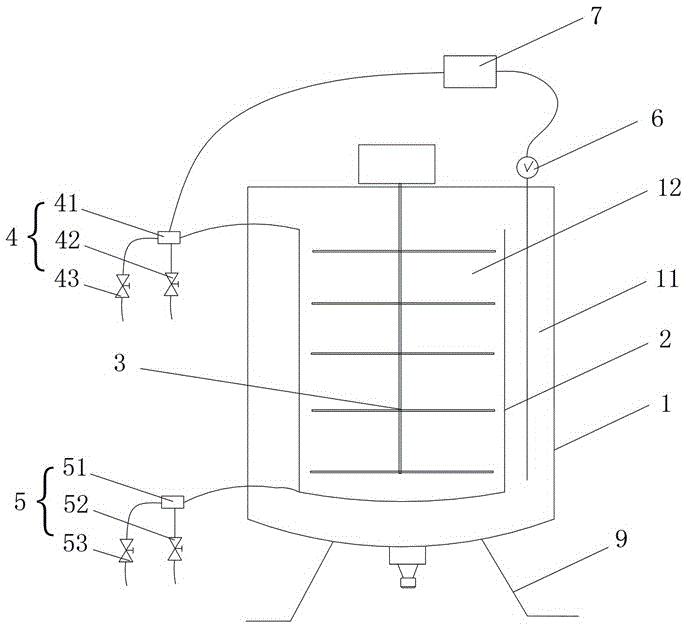

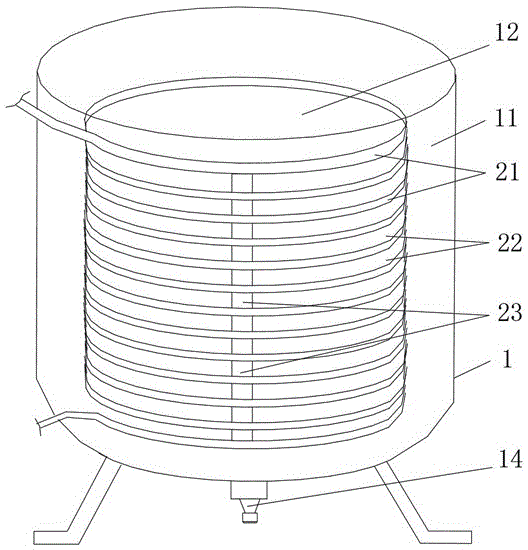

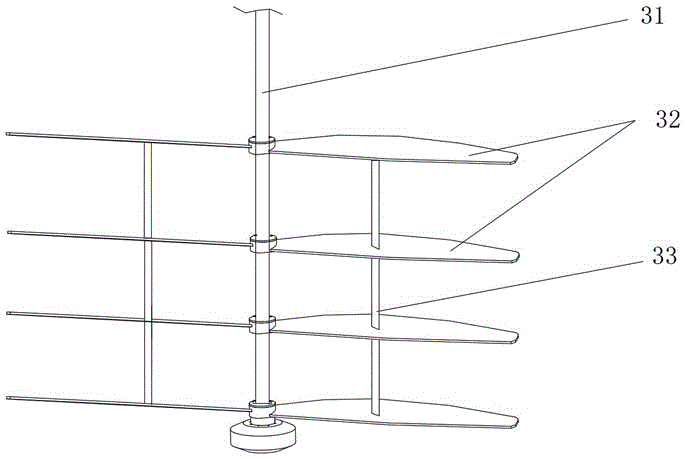

[0035] Such as Figure 1 to Figure 4 As shown, the present invention provides a crystal melting device for honey, including a tank 1 for loading honey. The tank 1 is provided with a matching heating and cooling assembly 2 and a stirring assembly 3, and the heating and cooling assembly 2 is provided by a pipe 21 is arranged in a spiral disk to form a hollow cylindrical body, and two adjacent layers of pipes 21 are spaced to form a pipe spacer layer 22; the head and tail of the pipe 21 extend out of the tank 1, and the head is provided with The first valve assembly 4 enables the pipeline 21 to communicate with the external high temperature medium source and the external cooling medium source at the same time, so that the high temperature medium enters the pipeline 21 when the crystal is melted / or the cooling medium enters the pipeline 21 after the crystal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com