Manufacturing method of gradient tissue engineering scaffold

A technology of gradient structure and production method, applied in the direction of tissue regeneration, additive processing, instruments, etc., can solve the problems of poor bonding/casting interface strength, difficult quantitative mechanical strength optimization, insufficient bionic mechanical strength, etc. Regeneration, Facilitate Biomimetic Optimization, Optimized Effect of Biomimetic Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

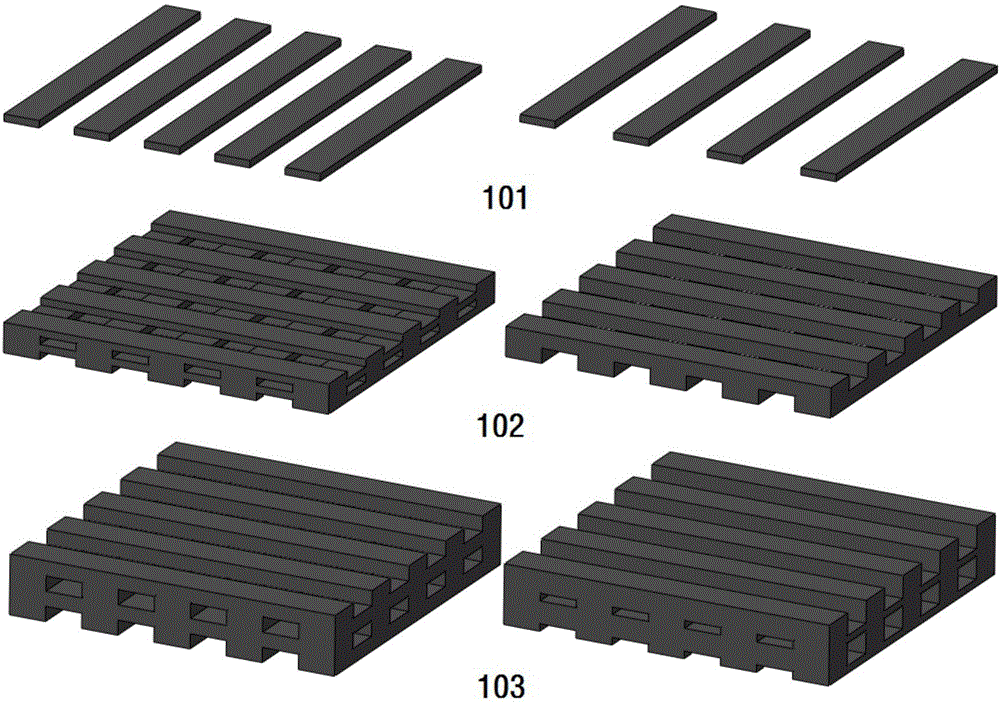

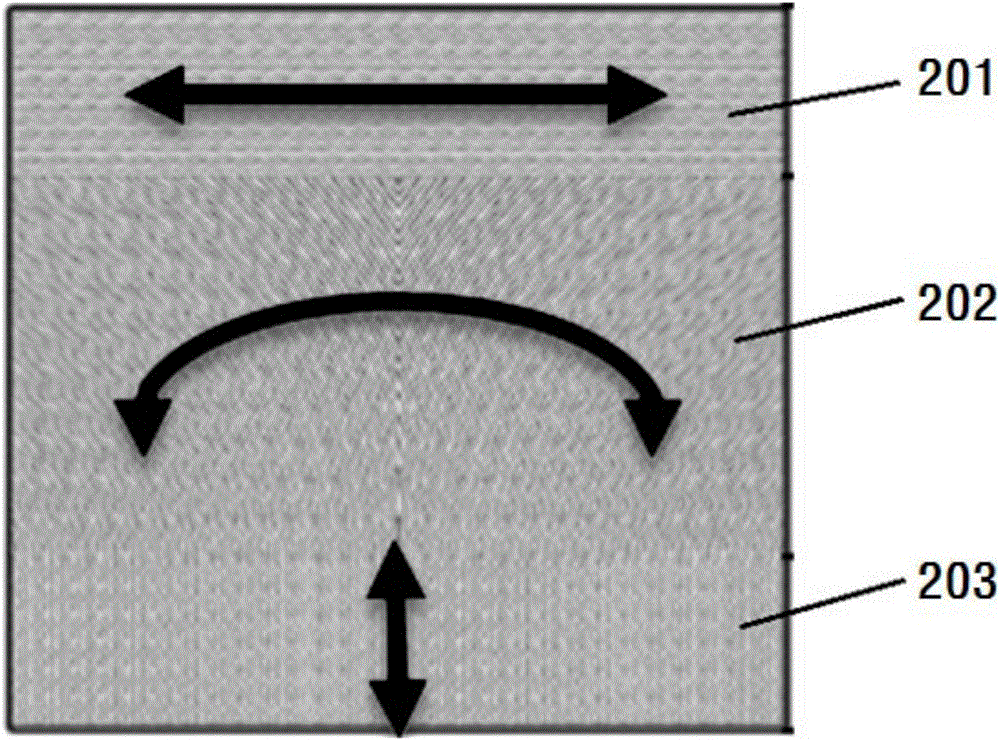

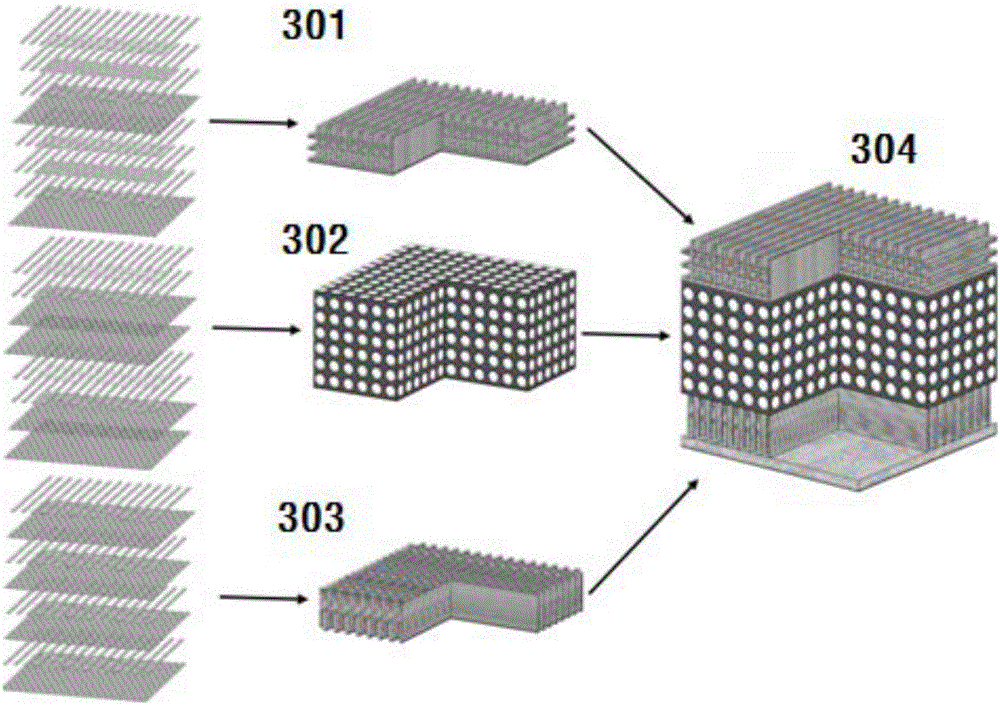

[0035] refer to Figure 1 to Figure 6 , in one embodiment, a method for fabricating a gradient tissue engineering scaffold, comprising using biopolymer materials and hydrogels, and using a low-temperature deposition 3D printer to print three kinds of grids to form a layered structure, respectively corresponding to shallow layers The tangential grid of tangential fibers, the uniform grid corresponding to the transition fibers in the middle layer, and the normal grid corresponding to the normal fibers in the bottom layer form a grid support, which has the ability to resist pressure from shallow to deep in terms of mechanical strength Gradually increasing, the shear resistance gradually decreases from shallow to deep; after printing, the first freeze-dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com