Reflow soldering furnace and control system thereof

A reflow soldering furnace and control device technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing production efficiency, taking a long time, and increasing costs, so as to save energy, save inert gas, and ensure The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

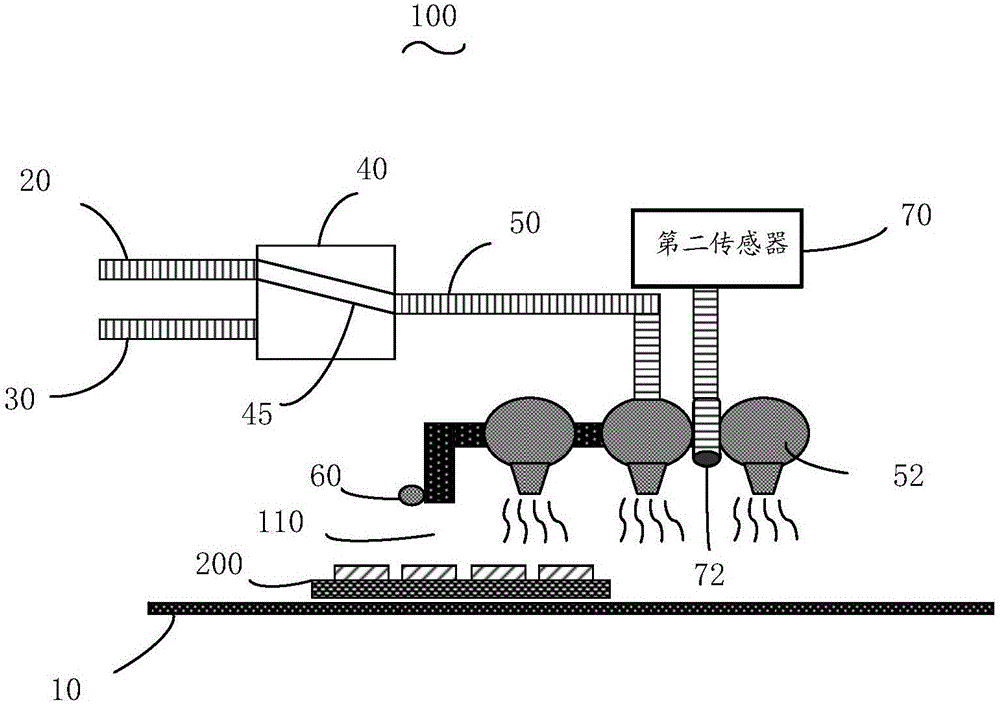

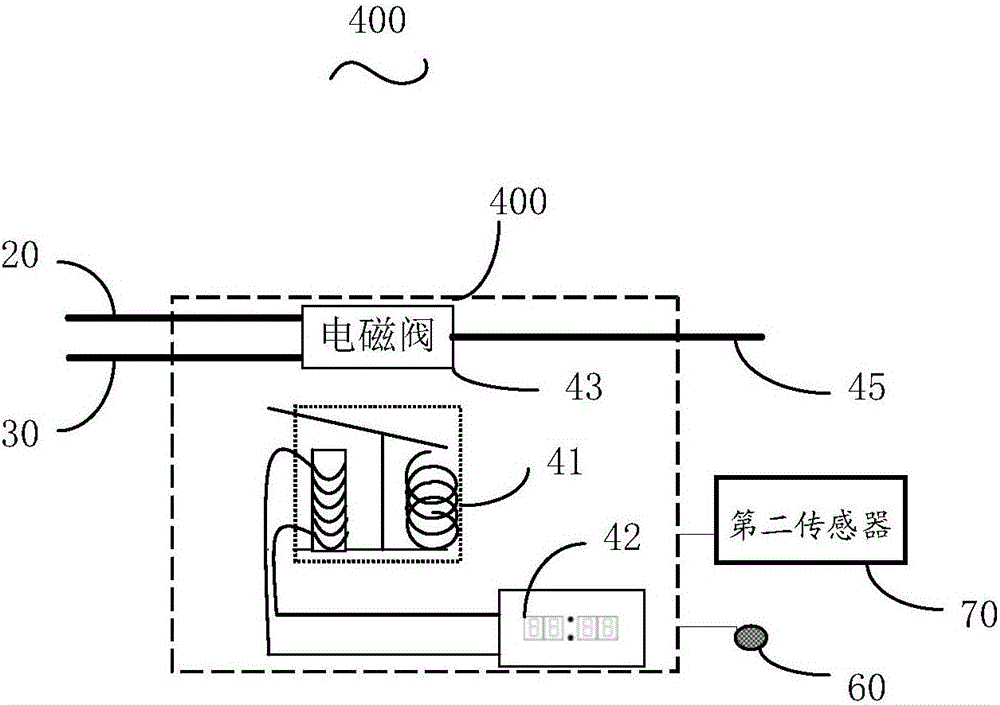

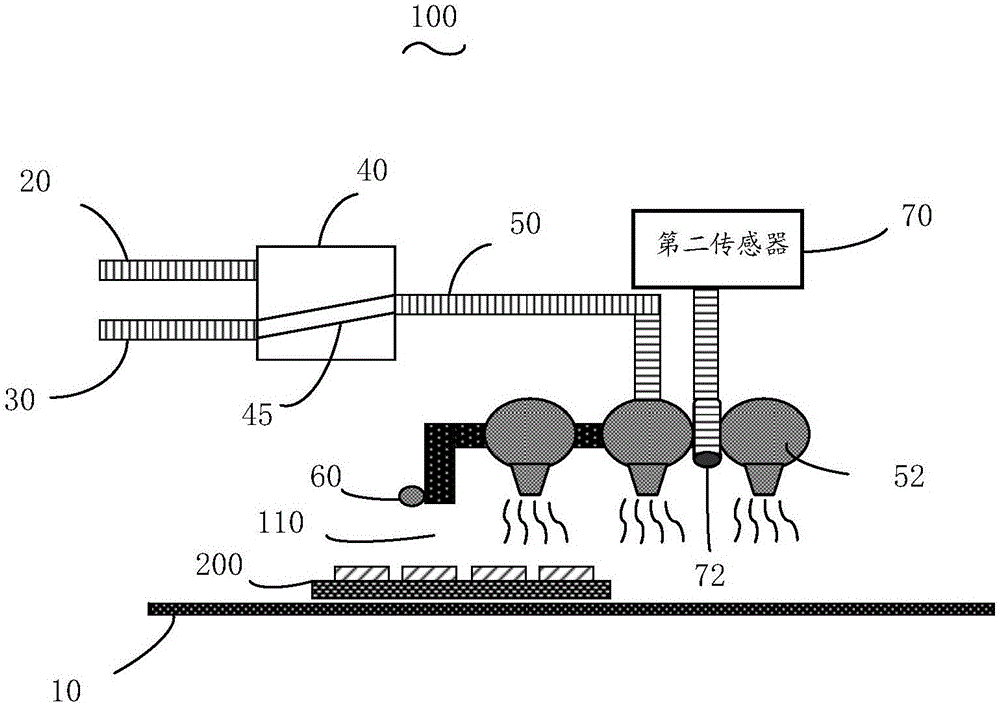

[0021] See figure 1 , figure 1 It is a schematic diagram of the structure of the first embodiment of the reflow soldering furnace 100 of the present invention, including a conveying device 10, a first input pipe 20, a second input pipe 30, a pipe control device 40, an air outlet pipe 50, a first sensor 60 and a second Sensor 70.

[0022] In this embodiment, the conveying device 10 is a guide rail capable of horizontal and bidirectional transmission, and the conveying device 10 penetrates the reflow oven 100. The reflow soldering furnace 100 is provided with a feed opening 110, and the product 200 enters the cavity of the reflow soldering furnace 100 along the conveying device 10 through the feed opening 110. The first sensor 60 is disposed on the outside of the furnace wall 120 of the reflow soldering furnace 100 adjacent to the inlet 110. The first sensor 60 is a feed sensor and is used to detect whether a product enters the reflow oven 100. The second sensor 70 is an oxygen a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com