Lifting mechanism control system with hydraulic gear-shifting transmission and glide-hook detecting method

A hoisting mechanism and control system technology, applied in the direction of the clockwork mechanism, the hoisting device, etc., can solve the problems affecting the safety of hoisting machinery, insufficient pressure of the shift valve, slipping hook of the hoisting mechanism, etc., and achieve real-time performance. And the control performance is good, the detection method is simple, and the effect of ensuring the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the drawings and embodiments.

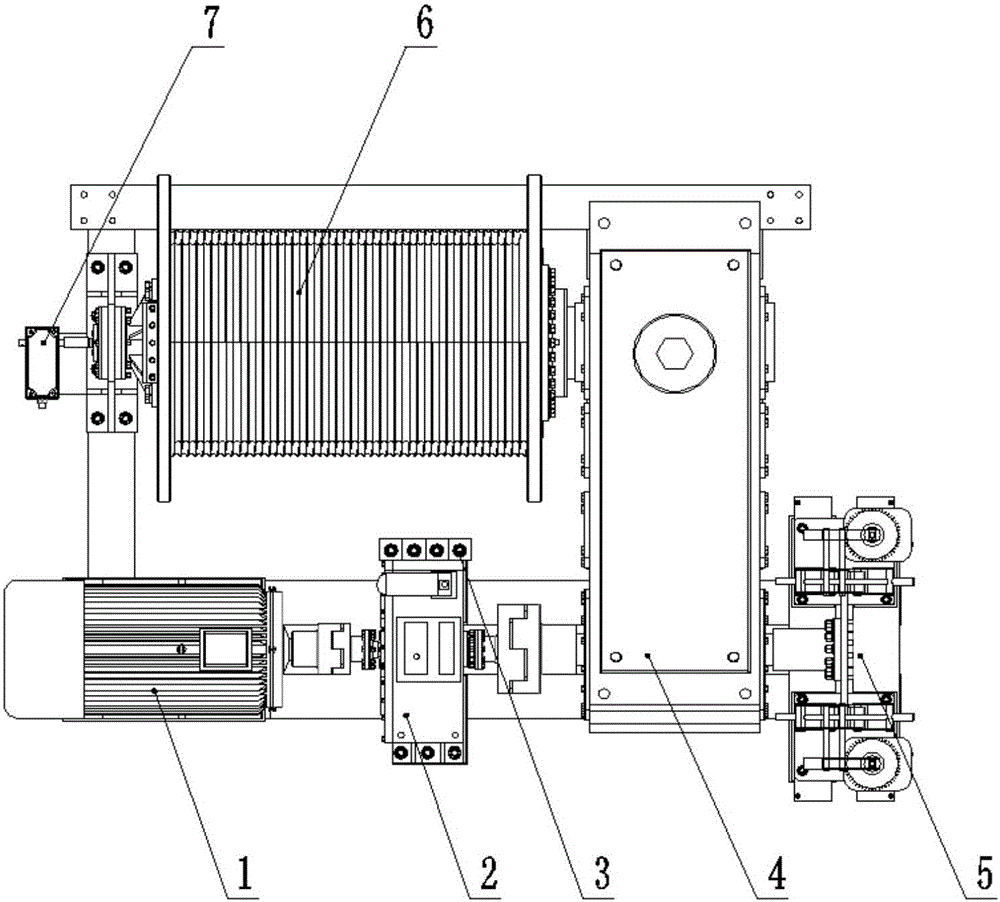

[0019] figure 1 Shown is the installation diagram of the pressure signal acquisition device and the reel forward and reverse detection device of the present invention.

[0020] The invention is applied to a lifting mechanism with a hydraulic shift transmission. The lifting mechanism includes an electric motor 1, a hydraulic shift transmission 2, a pressure signal acquisition device 3, a reducer 4, a brake 5, a reel 6, and a reel Forward and reverse detection device 7. Compared with the conventional lifting mechanism, this lifting mechanism is provided with a hydraulic shift transmission 2 between the electric motor 1 and the reducer 4, and a pressure signal acquisition device 3 is added on the hydraulic shift transmission 2. A set of reel forward and reverse detection device 7 is added to the tail of the reel.

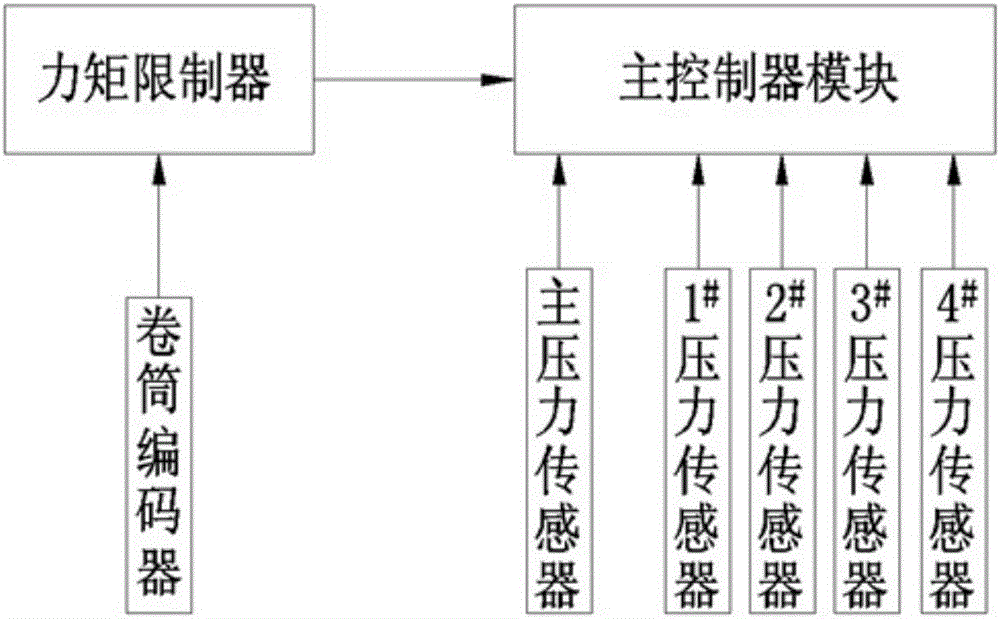

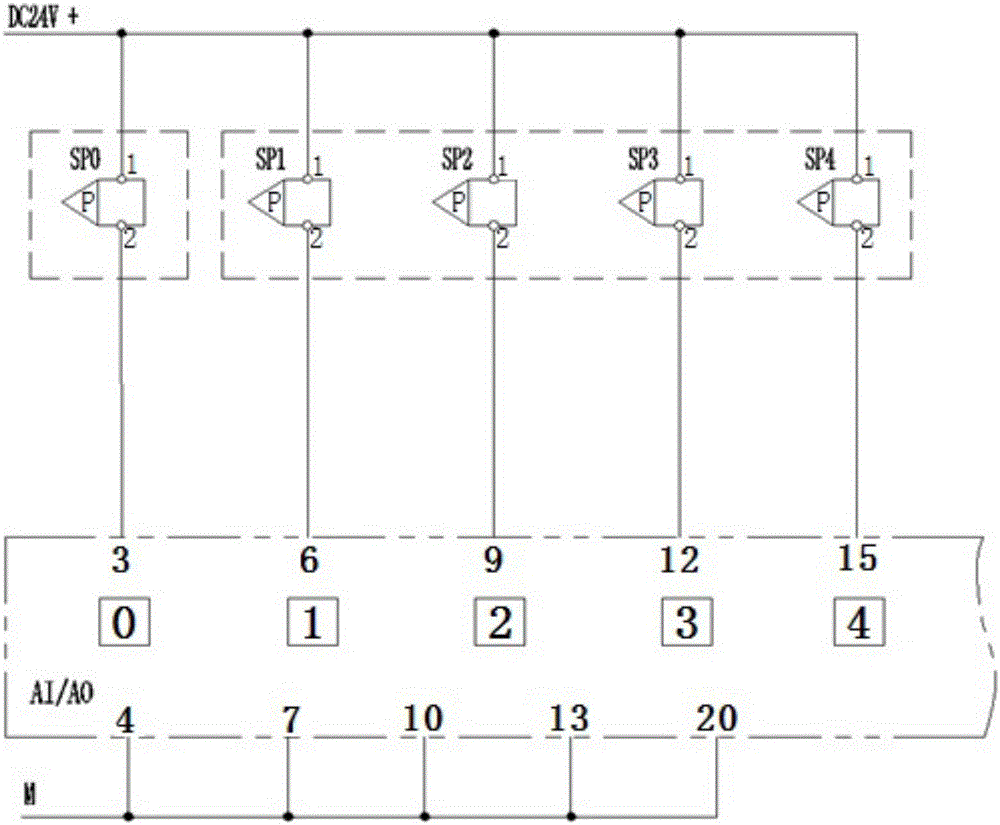

[0021] The control system of the present invention includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com