Method for preparing chlorine dioxide from composite chlorate

A chlorine dioxide and chlorate technology, applied in chlorine dioxide, chlorine oxide and other directions, can solve problems such as large safety hazards, and achieve the effects of stable quality, simple and convenient operation, and ensuring output and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

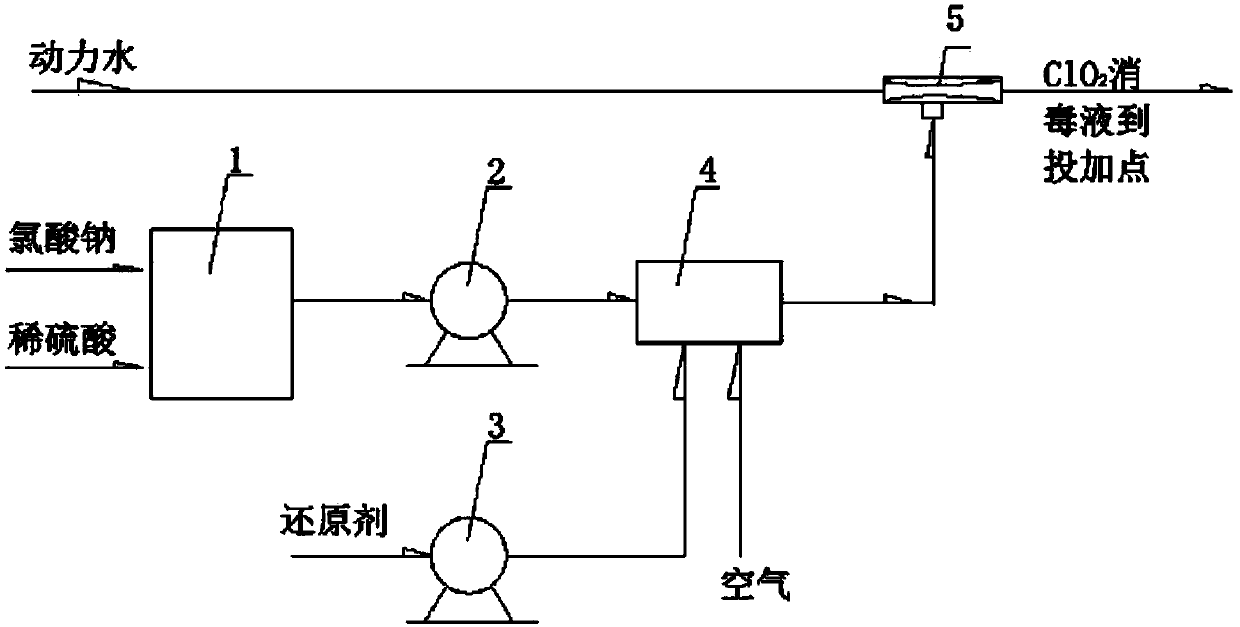

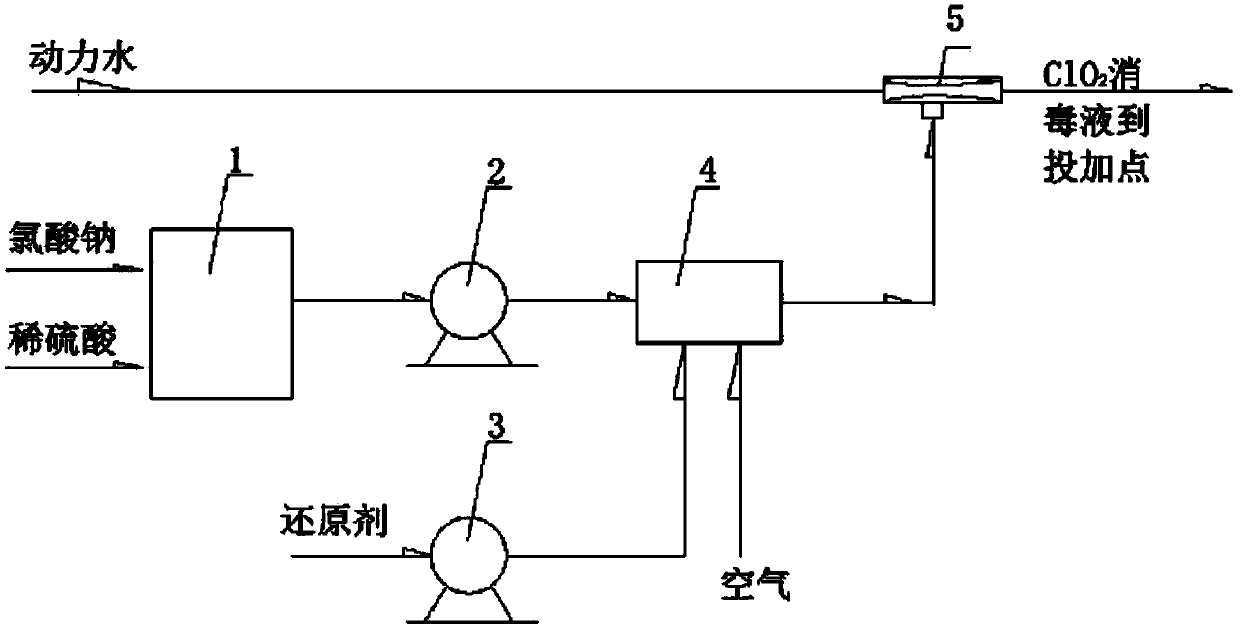

Image

Examples

preparation example Construction

[0026] Wherein the preparation method of compound chlorate solution is as follows:

[0027] (a) Prepare chlorate solution: mix and dissolve chlorate and water to form a chlorate solution with a concentration of 28-35% by mass. If the concentration of chlorate is too low, the chemical reaction time will be prolonged and the output of chlorine dioxide will be reduced; if the concentration of chlorate is too high, it will crystallize at normal temperature, which will affect the use. Described chlorate is one or its mixture in sodium chlorate, potassium chlorate, barium chlorate, preferably sodium chlorate.

[0028] (b) preparing dilute sulfuric acid solution: dilute the concentrated sulfuric acid with water to form a dilute sulfuric acid solution with a concentration of 60-80% by mass. If the concentration of sulfuric acid is too low, it will affect the chemical reaction speed and reduce the conversion rate of raw materials; if the concentration of sulfuric acid is too high, it ...

Embodiment 1

[0035] Example 1: An implementation case of controlling the temperature of the reaction system at 60°C

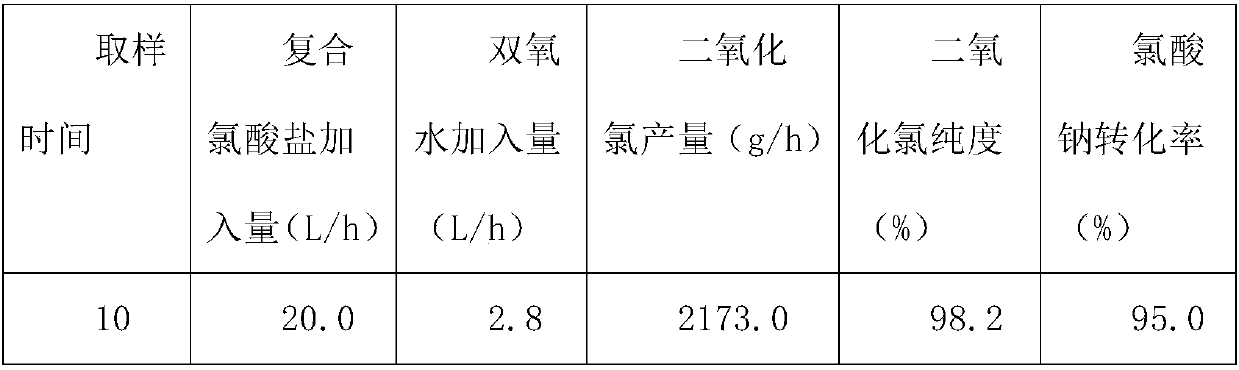

[0036] Be that the sodium chlorate content is 12.0%, sulfuric acid content is that the composite chlorate solution of 33.0% joins in the chlorine dioxide vessel with the flow rate of 20L / h with metering pump, simultaneously content is the hydrogen peroxide of 27.5% with metering pump at 2.8 The flow rate of L / h is added to the reactor, the temperature of the material is controlled at 60°C, and the reactor is maintained at a negative pressure with a water injector, and the chlorine dioxide is extracted and mixed with water to form a chlorine dioxide solution. The test data are shown in Table 1. :

[0037]

[0038]

[0039] The output of chlorine dioxide in this case is 2175g / h, the conversion rate of main raw material sodium chlorate is 95.1%, and the purity of chlorine dioxide is 98.4%.

Embodiment 2

[0040] Example 2: Controlling the temperature of the reaction system at 65°C

[0041] Be that the sodium chlorate content is 14.0%, sulfuric acid content is that the composite chlorate solution of 35.0% joins in the chlorine dioxide generator with the flow rate of 40L / h with metering pump, simultaneously content is the hydrogen peroxide of 27.5% with metering pump The flow rate of 5.6L / h is added to the reactor of the generator, the temperature of the material is controlled at 65°C, and the reactor is maintained at a negative pressure with a water injector, and the chlorine dioxide is extracted and mixed with water to form a chlorine dioxide solution. The data is shown in Table 2:

[0042]

[0043] The output of chlorine dioxide in this embodiment is 4666.3g / h, the conversion rate of main raw material sodium chlorate is 95.3%, and the purity of chlorine dioxide is 98.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com