Continuous emulsion liquid membrane extraction device and recovery process of epichlorohydrin wastewater

A technology of epichlorohydrin and emulsion liquid film, which is applied in the field of water treatment, can solve the problems of difficult treatment and achieve the effect of continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

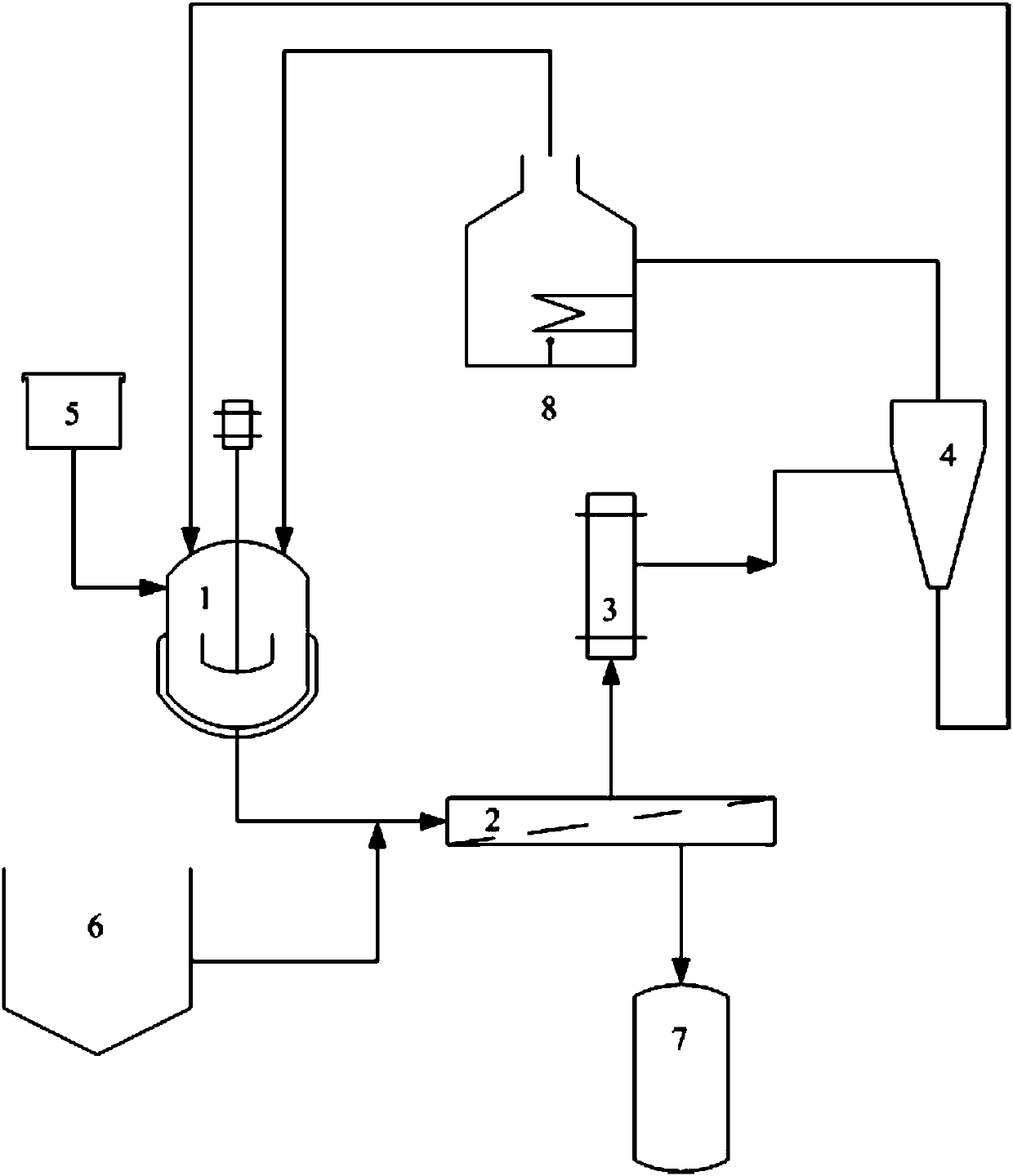

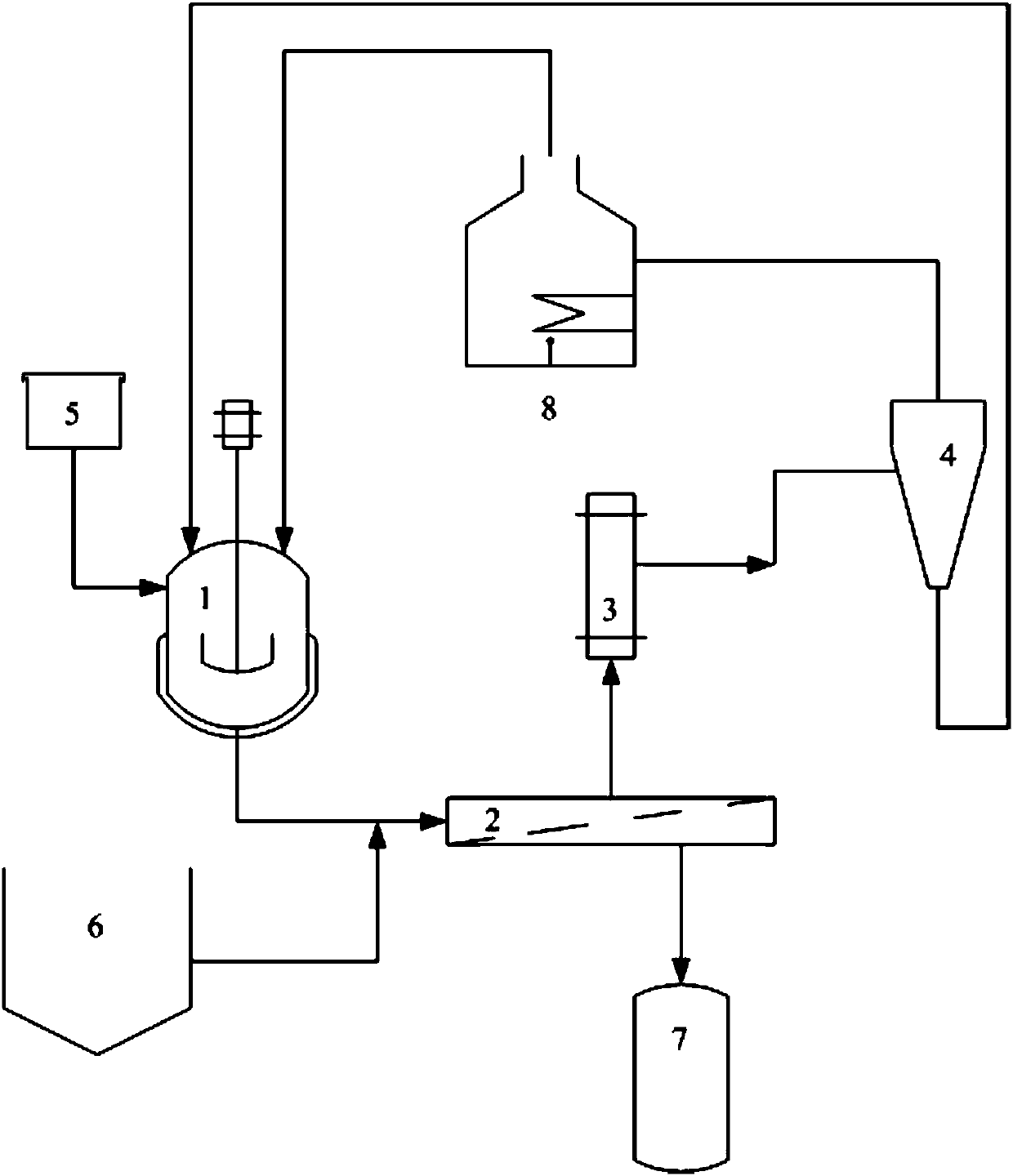

Method used

Image

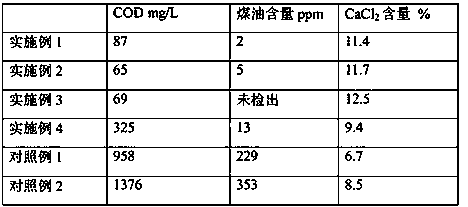

Examples

Embodiment 1

[0041] Step 1, preparation of emulsion liquid membrane: Dissolve the surfactant Span65 in the membrane solvent, add the carrier tri-n-octylamine, membrane aid kerosene and 25wt% NaCl in the inner phase of the salt solution, and stir at a high speed of 2000-2500rpm after mixing Emulsification to obtain a water-in-oil emulsion film, wherein the weight ratio range among surfactant, film solvent, carrier, film aid, and salt solution internal phase liquid is 1:100:80:6:10;

[0042] Step 2, extraction: feed the water-in-oil emulsion liquid membrane and epichlorohydrin waste water into the channel of the tubular porous ceramic filter 2 according to the volume ratio of 1:10, and the mixed material liquid flows through the tubular porous ceramic filter The flow velocity in the channel of 2 is 0.1m / s, and the feed liquid pressure is 0.1bar. After cross-flow filtration, the saline solution seeps out from the pipe wall, and organic impurities enter the liquid film; the tubular ceramic filt...

Embodiment 2

[0047]The first step is to prepare the emulsion liquid membrane: dissolve the surfactant Span65 in the membrane solvent, and add the carrier tri-n-octylamine, membrane aid kerosene and 25wt% NaCl in the inner phase of the salt solution, and mix and emulsify at a high speed of 2500rpm A water-in-oil type emulsion liquid film is obtained, wherein the weight ratio range among surfactant, film solvent, carrier, film aid, and salt solution internal phase liquid is 1: 120: 90: 12: 15;

[0048] Step 2, extraction: feed the water-in-oil emulsion liquid membrane and epichlorohydrin waste water into the channel of the tubular porous ceramic filter 2 according to the volume ratio of 1:20, and the mixed material liquid flows through the tubular porous ceramic filter The flow velocity in the channel of 2 is 0.5m / s, and the feed liquid pressure is 0.5bar. After cross-flow filtration, the saline solution seeps out from the pipe wall, and organic impurities enter the liquid film; the tubular c...

Embodiment 3

[0053] The first step is to prepare the emulsion liquid membrane: dissolve the surfactant Span65 in the membrane solvent, and add the carrier tri-n-octylamine, membrane aid kerosene and 25wt% NaCl in the inner phase of the salt solution, and mix and emulsify at a high speed of 2200rpm A water-in-oil type emulsion liquid film is obtained, wherein the weight ratio range among the surfactant, the film solvent, the carrier, the film aid, and the internal phase liquid of the salt solution is 1:110:85:7:12;

[0054] Step 2, extraction: feed the water-in-oil emulsion liquid membrane and epichlorohydrin waste water into the channel of the tubular porous ceramic filter 2 according to the volume ratio of 1:15, and the mixed material liquid flows through the tubular porous ceramic filter The flow velocity in the channel of 2 is 0.3m / s, and the feed liquid pressure is 0.3bar. After cross-flow filtration, the saline solution seeps out from the pipe wall, and organic impurities enter the liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com