Polyurethane resin for slow rebound sponge, preparation method and application

A technology of polyurethane resin and slow rebound sponge is applied in the fields of polyurethane resin for slow rebound sponge and its preparation and application, which can solve the problem of high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

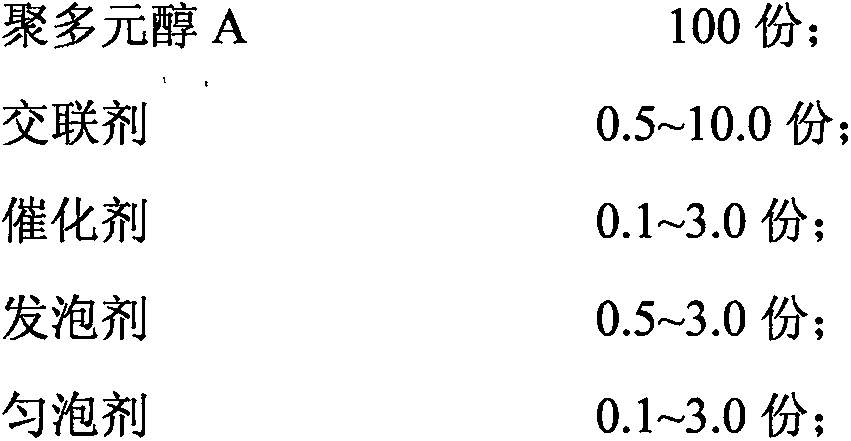

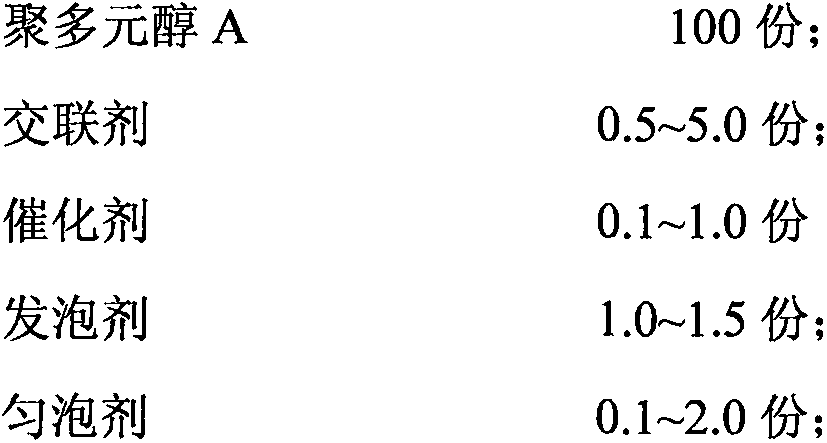

Method used

Image

Examples

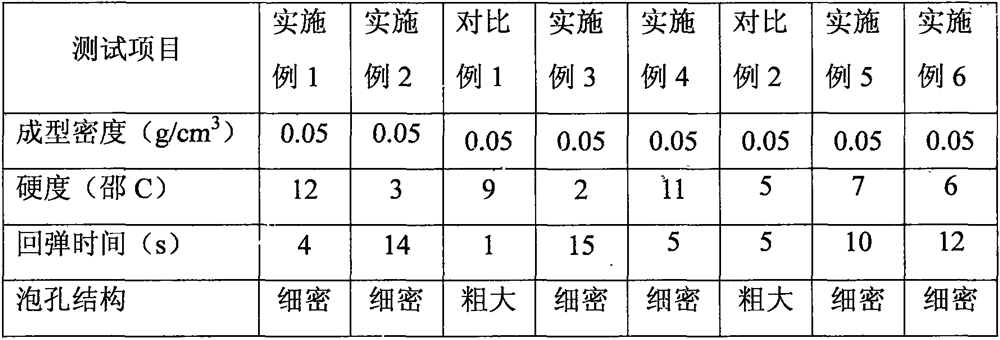

Embodiment 1

[0055] The polyoxyethylene-oxypropylene trihydric alcohol (number average molecular weight is 6000) of 144.3kg, the polyoxypropylene ether trihydric alcohol (number average molecular weight 300) of 86.6kg, the styrene graft copolymerized polyoxyethylene-oxypropylene of 46.2kg Trihydric alcohol (number-average molecular weight is 6000), 1.39kg ethylene glycol, the ethylene glycol solution of the triethylenediamine of 0.22kg, the bis (dimethylaminoethyl) ether of 0.89kg 70wt% and 30wt% ash A solution made of dipropylene glycol, 2.77kg of water and 0.28kg of silicone foam stabilizer were reacted at 50°C for 2.5h, cooled to 40°C, and mixed for 1.5h to obtain polyurethane resin component A.

[0056] With 119.8kg of diphenylmethane diisocyanate, 39.8kg of carbodiimide modified diphenylmethane diisocyanate, 1.99kg of polyoxyethylene-oxypropylene trihydric alcohol (number average molecular weight is 6000) and 0.0040kg of Phosphoric acid was reacted at 65°C for 3 hours to obtain compon...

Embodiment 2

[0060]The polyoxyethylene-oxypropylene trihydric alcohol (number average molecular weight is 6000) of 144.3kg, the polyoxypropylene ether trihydric alcohol (number average molecular weight 300) of 86.6kg, the styrene graft copolymerized polyoxyethylene-oxypropylene of 46.2kg Trihydric alcohol (the number average molecular weight is 6000), 1.39kg ethylene glycol, the ethylene glycol solution of the triethylenediamine of 0.22kg, the bis(dimethylaminoethyl) ether of 0.89kg 70wt% and 30wt% ash A solution made of dipropylene glycol, 2.77kg of water and 0.28kg of silicone foam stabilizer were reacted at 50°C for 2.5h, cooled to 40°C, and mixed for 1.5h to obtain polyurethane resin component A.

[0061] With 18.7kg of diphenylmethane diisocyanate, 6.21kg of carbodiimide modified diphenylmethane diisocyanate, 0.30kg of polyoxyethylene-oxypropylene trihydric alcohol (number average molecular weight is 6000) and 0.0009kg of Phosphoric acid was reacted at 65°C for 3 hours to obtain compo...

Embodiment 3

[0065] The polyoxyethylene-oxypropylene trihydric alcohol (number average molecular weight is 10000) of 89.8kg, the polyoxypropylene ether trihydric alcohol (number average molecular weight 1000) of 11.2kg, the acrylonitrile graft copolymerized polyoxyethylene-oxypropylene of 101.0kg Trihydric alcohol (the number average molecular weight is 10000), 2.02kg ethylene glycol, the ethylene glycol solution of the triethylenediamine of 1.01kg, the bis (dimethylaminoethyl) ether of 70wt% and 30wt% ash of 1.01kg A solution made of dipropylene glycol, 3.03kg of water and 4.04kg of silicone foam stabilizer were reacted at 60°C for 1.5h, cooled to 45°C, and mixed for 1.0h to obtain the polyurethane resin component A.

[0066] With 7.99kg of diphenylmethane diisocyanate, 2.00kg of carbodiimide modified diphenylmethane diisocyanate, 2.00kg of polyoxyethylene-oxypropylene trihydric alcohol (number average molecular weight is 10000) and 0.002kg of Phosphoric acid was reacted at 75°C for 2 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com