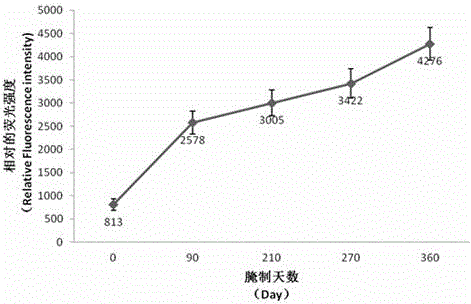

Method for rapidly detecting and quantifying activity of proteinase in dry-cured ham processing process

A protease activity, dry-cured ham technology, applied in the field of analytical chemistry, can solve problems such as undeveloped, achieve the effect of improving efficiency, reducing labor intensity, and accurate experimental results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A method for rapidly detecting and quantifying protease activity during dry-cured ham processing, comprising the steps of:

[0042] Step (1), making gelatin smears: add potassium chromium sulfate dodecahydrate and gelatin to water, heat to 68°C, put a clean sterile three-well glass slide in it after the gelatin is completely dissolved, and keep the temperature After 10 minutes, the three-well glass slide was taken out and dried naturally to obtain a gelatin smear; wherein, the mass ratio of potassium chromium sulfate dodecahydrate, gelatin and water was 0.43:2.4:3.5×10 3 ;

[0043] Step (2), sample collection and dilution: Under sterile conditions, cut the ham into pieces with a particle size of 2-4 cm for later use; then add sterilized 1×PBS with a pH of 7.0 to the ham pieces Buffer solution, after mixing, stir at 16000r / min for 1.5 minutes, then grind at 10000r / min for 1 minute to obtain meat paste; wherein, the mass-volume ratio of ham pieces to 1×PBS buffer is 1: ...

Embodiment 2

[0052] A method for rapidly detecting and quantifying protease activity during dry-cured ham processing, comprising the steps of:

[0053] Step (1), making gelatin smears: add potassium chromium sulfate dodecahydrate and gelatin to water, heat to 72°C, put a clean sterile three-well glass slide in it after the gelatin is completely dissolved, and keep the temperature After 15 minutes, the three-well glass slide was taken out and dried naturally to obtain a gelatin smear; wherein, the mass ratio of potassium chromium sulfate dodecahydrate, gelatin and water was 0.45: 2.6: 3.5×10 3 ;

[0054] Step (2), sample collection and dilution: Under sterile conditions, cut the ham into pieces with a particle size of 2-4 cm for later use; then add sterilized 1×PBS with a pH of 7.0 to the ham pieces Buffer, after mixing, stir at a speed of 18000r / min for 2.5 minutes, and then grind at a speed of 13000r / min for 3 minutes to obtain a meat paste; wherein, the mass-volume ratio of ham pieces t...

Embodiment 3

[0064] A method for rapidly detecting and quantifying protease activity during dry-cured ham processing, comprising the steps of:

[0065] Step (1), making gelatin smears: add potassium chromium sulfate dodecahydrate and gelatin to water, heat to 70°C, put a clean sterile three-well glass slide in it after the gelatin is completely dissolved, and keep the temperature , after 13 minutes, take out the three-well glass slide, and dry naturally to obtain a gelatin smear; wherein, the mass ratio of potassium chromium sulfate dodecahydrate, gelatin and water is 0.44:2.5:3.5×10 3 ;

[0066] Step (2), sample collection and dilution: Under sterile conditions, cut the ham into pieces with a particle size of 2-4 cm for later use; then add sterilized 1×PBS with a pH of 7.0 to the ham pieces Buffer solution, after mixing, stir at 17000r / min for 2 minutes, then grind at 12000r / min for 2 minutes to obtain meat puree; wherein, the mass-volume ratio of ham pieces to 1×PBS buffer is 1: 10;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com