Method for improving desulphurization efficiency of blast-furnace slag

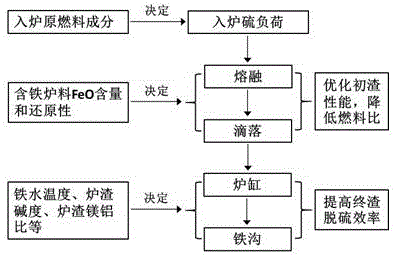

A technology for desulfurization efficiency and blast furnace slag, applied in blast furnaces, blast furnace details, furnaces, etc., can solve problems such as reduced energy utilization, increased slag alkalinity, and increased slag viscosity, so as to improve the performance of primary slag and reduce sulfur entering the furnace Load and the effect of lowering the fuel ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

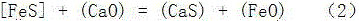

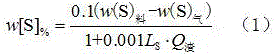

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: The method for improving the desulfurization efficiency of blast furnace slag adopts the following specific processes.

[0028] Blast furnace effective volume 1000m 3 , the molten iron temperature is 1495°C, the Si content in molten iron is 0.5wt%, the binary basicity of slag is 1.2, the ternary basicity of slag is 1.4, and the MgO content is 7.5wt%; other parameters and indicators are normal values.

[0029] Sintered ore into the furnace: FeO content 9wt%, SiO 2 Content 5.5wt%; reducing index 60%; other parameters and indexes are normal.

[0030] Furnace pellets: FeO content 0.5wt%, SiO 2 Content 8wt%, MgO content 0.5wt%, alkalinity 0.2, reducibility index 60%; other parameters and indexes are normal values.

[0031] The sulfur load into the blast furnace is 4kg / t-Fe, and the sulfur content in molten iron is less than 0.03wt%, which is qualified.

Embodiment 2

[0032] Embodiment 2: The method for improving the desulfurization efficiency of blast furnace slag adopts the following specific processes.

[0033] Blast furnace effective volume 1000m 3 , molten iron temperature 1500 ℃, molten iron Si content 0.55%; slag binary alkalinity 1.22, triple alkalinity 1.45, MgO content 7.5%; other parameters and indicators are normal.

[0034] Sintered ore into the furnace: FeO content 9%, SiO 2 Content 5.5%; reducing index 60%; other parameters and indicators are normal.

[0035] Furnace pellets: FeO content 0.5%, SiO 2 Content 8%, MgO content 0.5%, alkalinity 0.2, reducibility index 60%; other parameters and indexes are normal.

[0036] The sulfur load of the blast furnace is 4.5kg / t-Fe, and the sulfur content of the molten iron is less than 0.03%, which is qualified.

Embodiment 3

[0037] Embodiment 3: The method for improving the desulfurization efficiency of blast furnace slag adopts the following specific processes.

[0038] Blast furnace effective volume 1000m 3 , molten iron temperature 1500 ℃, molten iron Si content 0.55%; slag binary alkalinity 1.2, triple alkalinity 1.5, MgO content 10%; other parameters and indicators are normal.

[0039] Sintered ore into the furnace: FeO content 9%, SiO 2 Content 5.5%. Restorative indicators: 60%; other parameters and indicators are normal.

[0040] Furnace pellets: FeO content 0.5%, SiO 2 Content 8%, MgO content less than 0.5%, alkalinity less than 0.2, reducing index: 60%. Other parameters and indicators were normal.

[0041] When the sulfur load into the blast furnace is 5kg / t-Fe, the sulfur content of molten iron is less than 0.03%, which is qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com