A rolling guide mechanism

A rolling guide rail and guide rail technology, applied in the field of guide rails, can solve the problems of no rolling guide rails and few applications, and achieve the effects of simple and reliable structure, simple processing technology and rich application functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

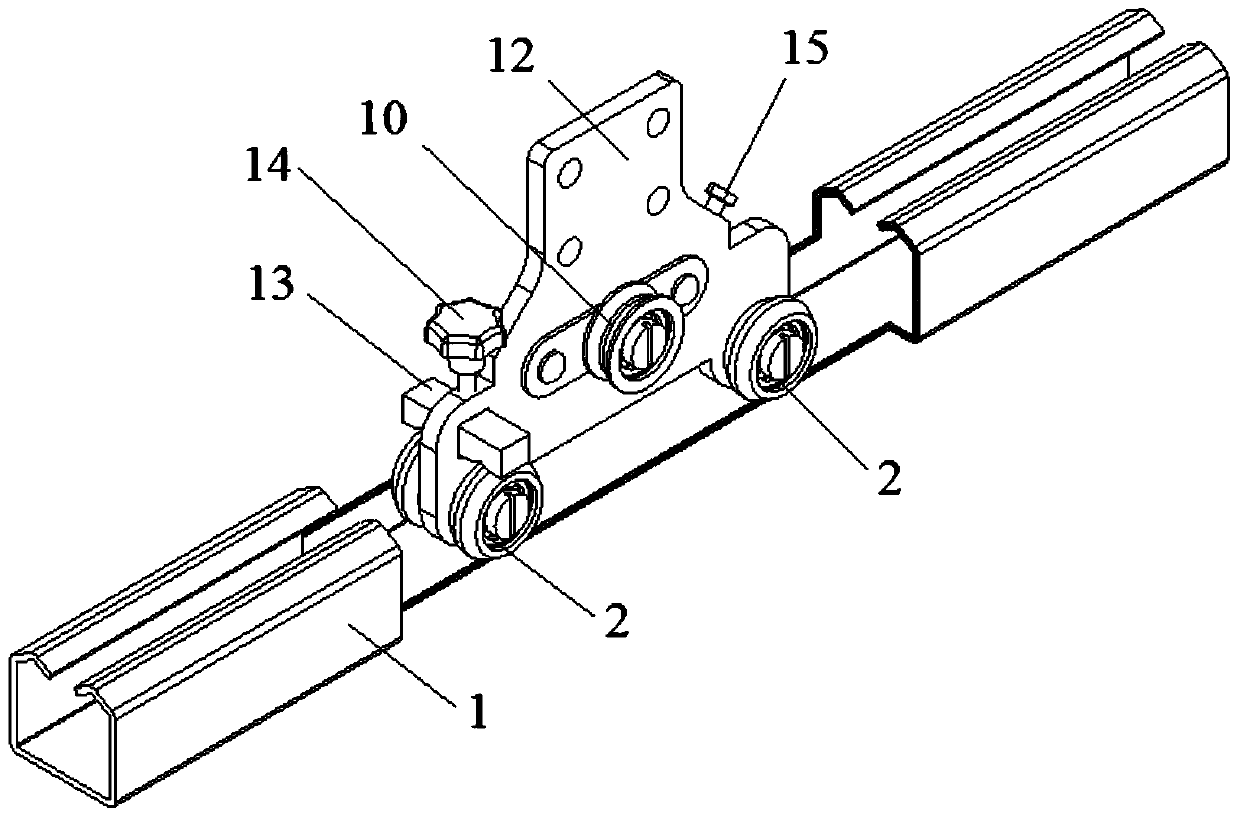

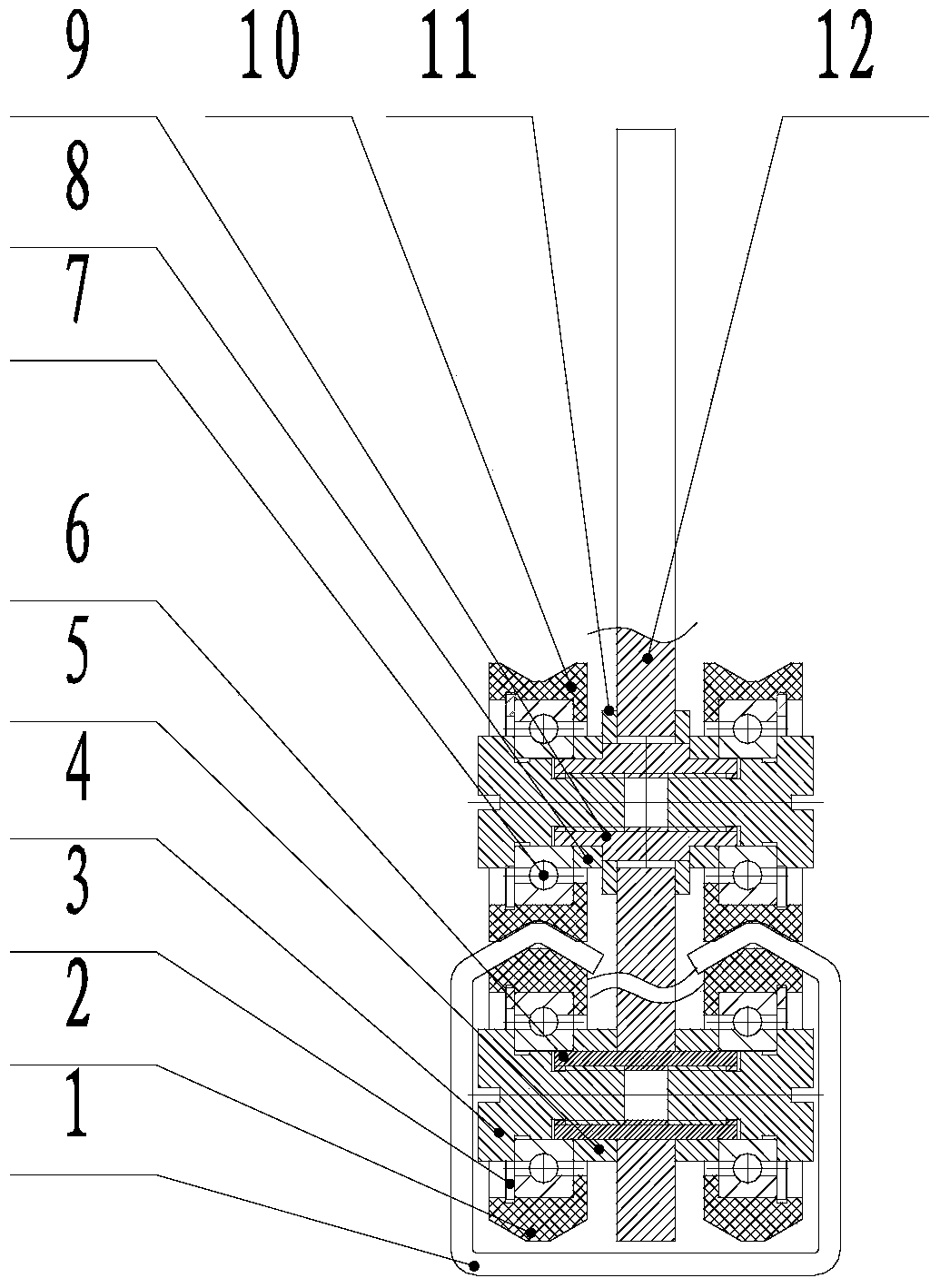

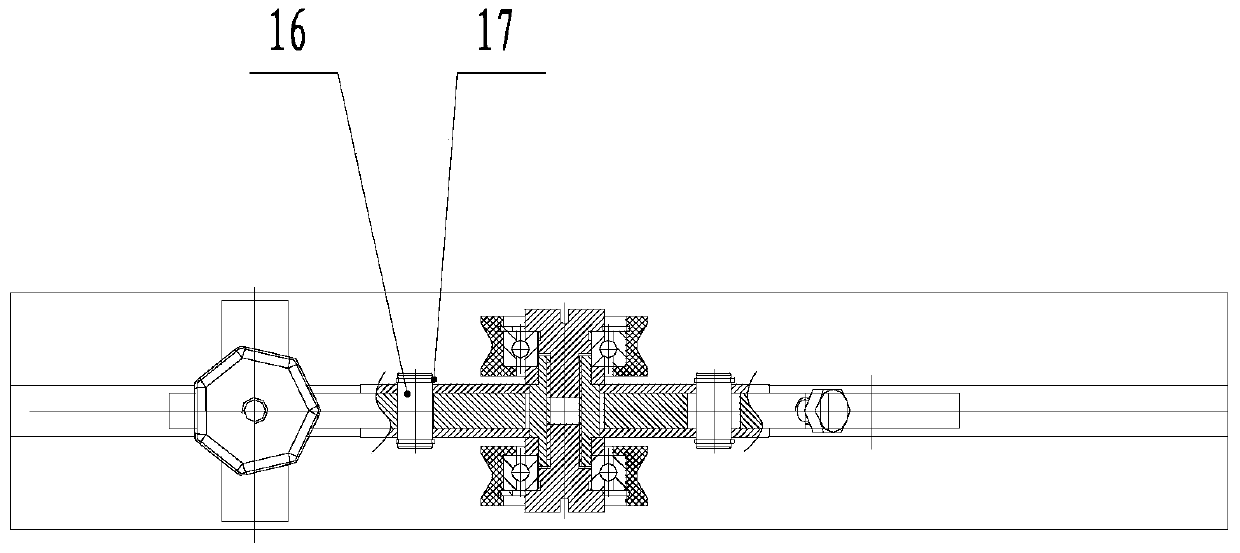

[0027] A rolling guide mechanism, its structure is as follows Figure 1-3 As shown, it includes a guide rail 1 composed of bent sheet metal parts, a slide seat composed of a slide body 12 and a brake shoe 13, a concave roller set connected to the slide seat and two sets of convex roller sets, wherein the concave roller set and the The outer side of the guide rail flange is attached, and the convex roller set is attached to the inner side of the guide rail flange. The three sets of roller groups can form the inner and outer three-point attachment of the two guide rail flanges. Realize that the pulley seat can only move along the direction of the guide rail, and its structure is as follows Figure 4 shown.

[0028] Specifically, each set of cam rollers consists of 2 cam rollers 2, 2 bearings 7, 2 retaining rings 3 for holes, 2 locking screws 4, 2 lower washers 5 and 1 lower screw sleeve 6 . A bearing 7 is adorned in each cam roller 2, and is fixed with a retaining ring 3 by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com