Strip-shaped dense type floor structure based on raw bamboos

A floor and strip technology, which is applied in the field of strip dense floor structure, can solve the problems of energy saving, environmental protection and low cost, and achieve the effect of high bearing capacity, improved bearing capacity and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

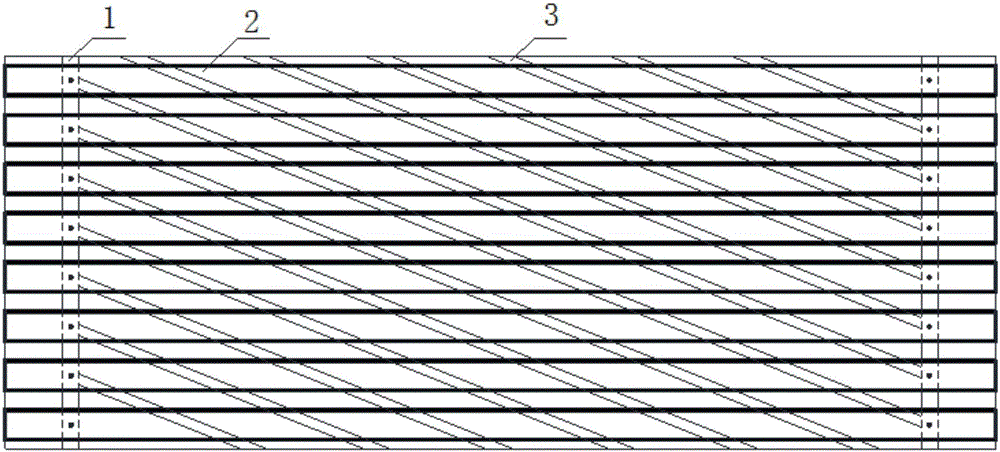

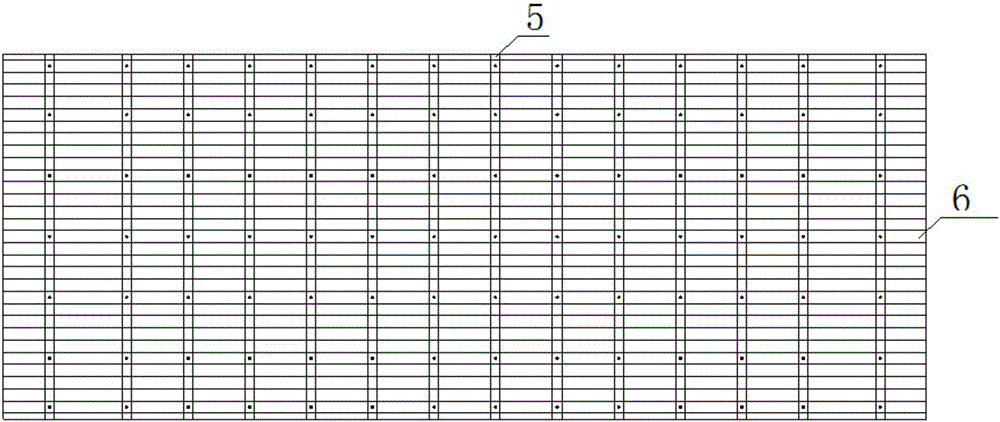

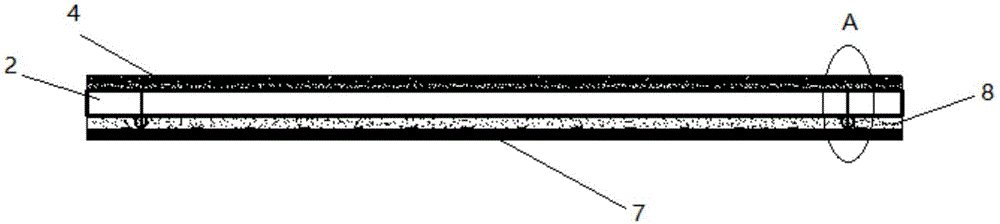

[0020] see Figure 1 to Figure 5 , the present invention comprises two original bamboos 1 vertically arranged in parallel, several floor beams 2 are horizontally fixed on the two original bamboos 1, several bamboo strips 3 are arranged above the floor beams 2, and distributed bamboo strips 5 are longitudinally arranged below the two original bamboos 1 , the force-bearing bamboo strips 6 are arranged horizontally, the force-bearing bamboo strips 6 are densely arranged, the adjacent force-bearing bamboo strips 6 are in contact, the lower decorative plate 7 is arranged below the stressed bamboo strips 6, and the bamboo strips 3 and the lower decorative plate 7 The space is filled with solid protection materials 8, and all the distribution bamboo strips 5 are arranged at equal intervals.

[0021] Preferably, the bamboo strips 3 intersect with the floor beams 2 .

[0022]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com