Roofing system about the metal surface core-board

A metal surface sandwich panel and metal surface technology, which is applied in the direction of flat/curved panel roofs, roofs, roof cladding, etc., can solve the problem of unfastened curling and overlapping connections and the thermal insulation effect of the joints of metal panels Inadequate, buckle off and other problems, to achieve the effect of simple structure, reasonable design, improve thermal insulation and waterproof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

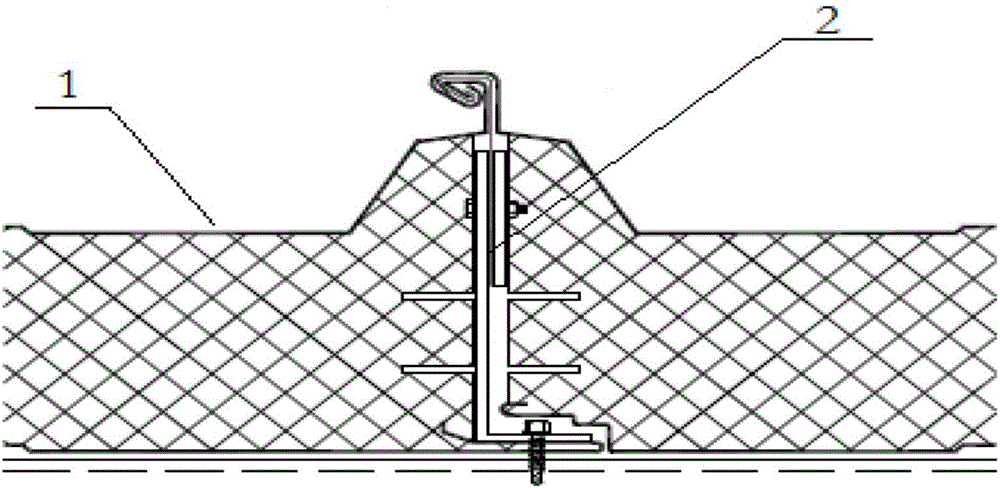

[0025] In this embodiment, a metal-surface sandwich panel roofing system includes several metal-surface sandwich roof panels 1; adjacent metal-surface sandwich roof panels 1 are connected by undercuts and adjacent to the metal-surface sandwich roof panels There is a gap between the end faces at the junction of panel 1;

[0026] Such as figure 1 As shown, at the purlin, a fixing device 2 is provided in the gap adjacent to the end face of the metal-faced sandwich roof panel 1; the upper end of the fixing device 2 is connected to the top undercut of the metal-faced sandwich roof panel 1 The lower end of the fixing device 2 is fixedly connected to the purlin through the bottom of the metal surface sandwich roof panel 1 through bolts;

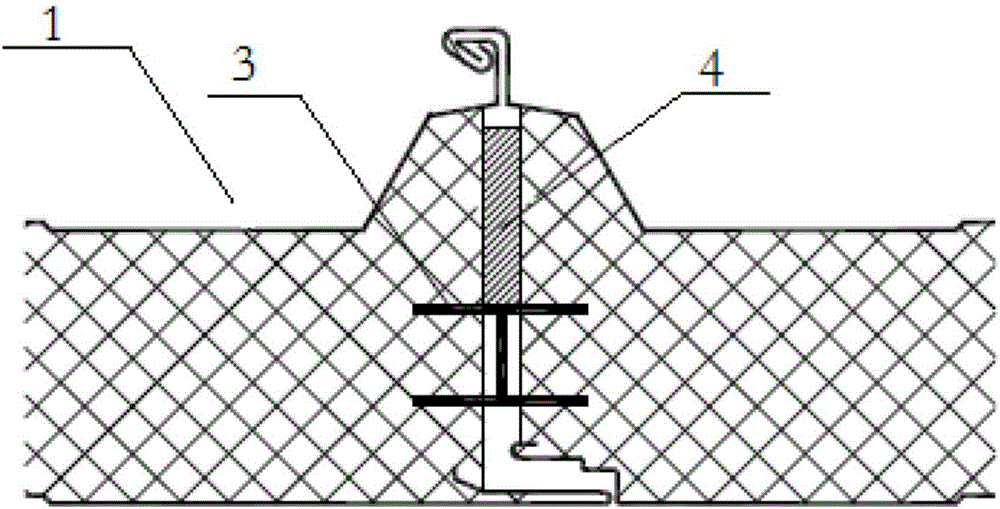

[0027] Such as figure 2 As shown, between the purlins, a heat-insulating insert 3 is provided in the gap between the end surfaces adjacent to the joints of the metal-faced sandwich roof panels 1; above the heat-insulating insert 3 is filled with ...

Embodiment 2

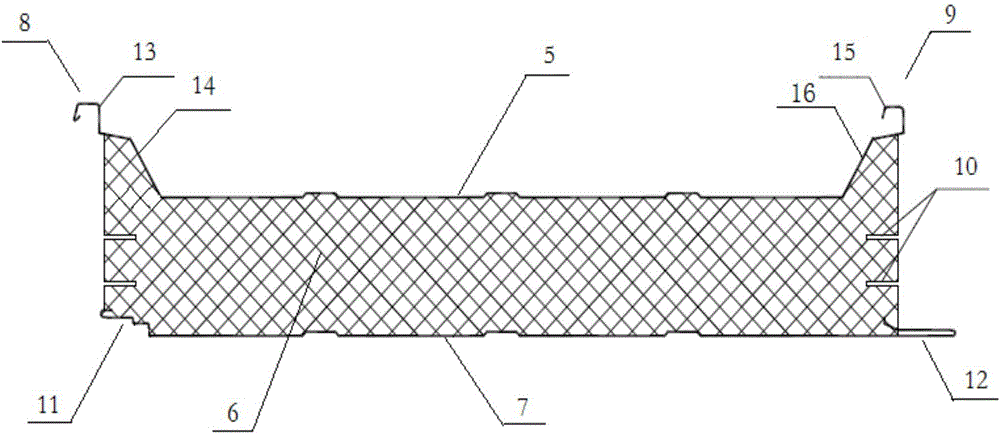

[0031] Such as image 3 As shown, based on the above-mentioned embodiment, the metal-faced sandwich roof panel 1 of this embodiment includes an upper base plate 5, a bottom plate 7, and an insulating layer 6 filled between the upper base plate 5 and the base plate 7; Layer 6 is bonded to the upper substrate 5 and the bottom plate 7;

[0032] The upper substrate includes a female side 8 and a male side 9 integrally formed at both ends;

[0033] The heat insulation layer 6 includes two reserved grooves 10 arranged on the end face for installing the heat insulation insert 3;

[0034] The bottom plate 7 includes an upwardly protruding protruding section 11 integrally formed with both ends and an extension section 12 coplanar with the bottom plate 7; the protrusion height of the protrusion section 11 is greater than the thickness of the extension section 12; When the metal surface sandwich roof panel 1 is connected, the extension section 12 extends into the protruding section 11;...

Embodiment 3

[0043] Based on the above embodiment, the upper substrate 5 is a cold-rolled thin steel plate; the upper substrate 5 also includes an anti-rust layer hot-dipped or coated on the outer surface of the upper substrate 5 .

[0044] Between the male side 9 of the upper base plate 5 and the female side 8, there are several ribs bent by the upper base plate 5; the height difference between the upper end of the ribs and the upper base plate 5 is 2-4 mm; the bottom plate 7 is also provided with a number of convex ribs bent by the bottom plate 7 at positions corresponding to the convex ribs of the upper base plate 5;

[0045] The antirust layer described in this embodiment is used to isolate the air to prevent oxidation; the convex ribs are used to improve the rigidity and ensure the overall rigidity of the upper base plate 5 and the bottom plate 7; prevent heavy objects from squeezing and deforming the metal surface sandwich roof panel .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com