Servo-pump-controlled hydraulic rotary driving system and control method

A technology of slewing drive and servo drive, which is applied in transmission control, transmission, fluid transmission, etc. It can solve the problems of difficult hydraulic motor servo control, increase system loss, difficult maintenance, etc., and achieve wide-range speed ratio adjustment, The effect of high reliability of the oil circuit and simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

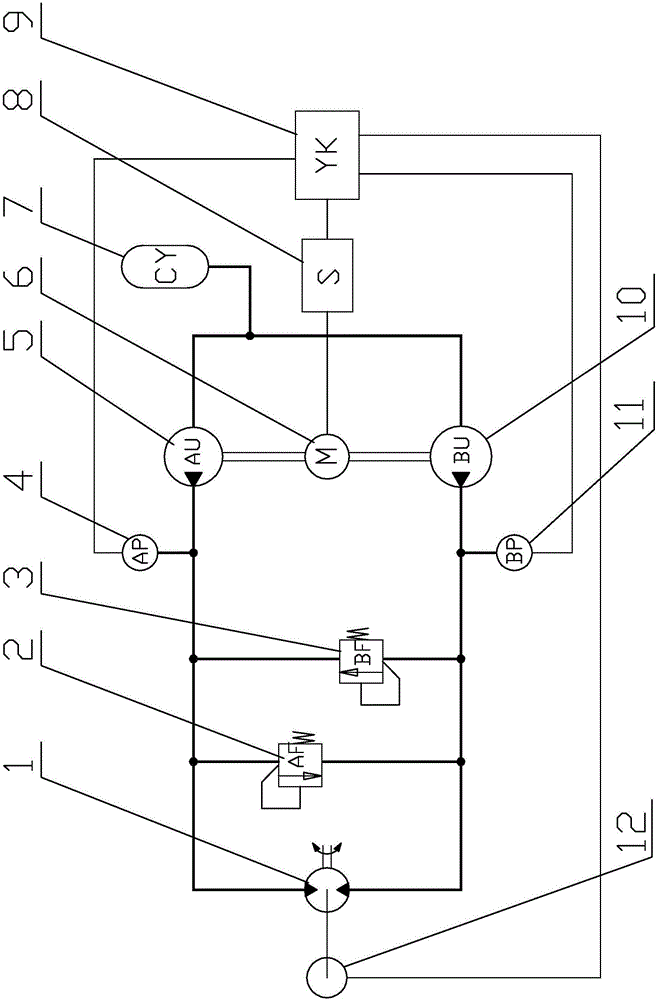

[0034] Embodiment 1 of the servo pump-controlled hydraulic rotary drive system is as follows: figure 1 As shown, the thick solid line connecting the components in the figure indicates the oil pipeline between the components, the thin solid line indicates the electrical connection between the electrical components, and the dotted line indicates the coupling between the angular displacement sensor and the hydraulic motor , the double solid line indicates the coupling between the shaft extension of the servo motor and the hydraulic pumps A and B.

[0035] A hydraulic pump 5 (shown as AU in the figure) and B hydraulic pump 10 (shown as BU in the figure) are both forward pumps, and their displacements are equal, and they are respectively connected to servo motor 6 (shown as M in the figure). Front axle extension and rear axle extension coupling. The liquid outlet of the A hydraulic pump 5 is connected to the forward oil inlet of the hydraulic motor 1 through the pipeline, and the ...

Embodiment 2

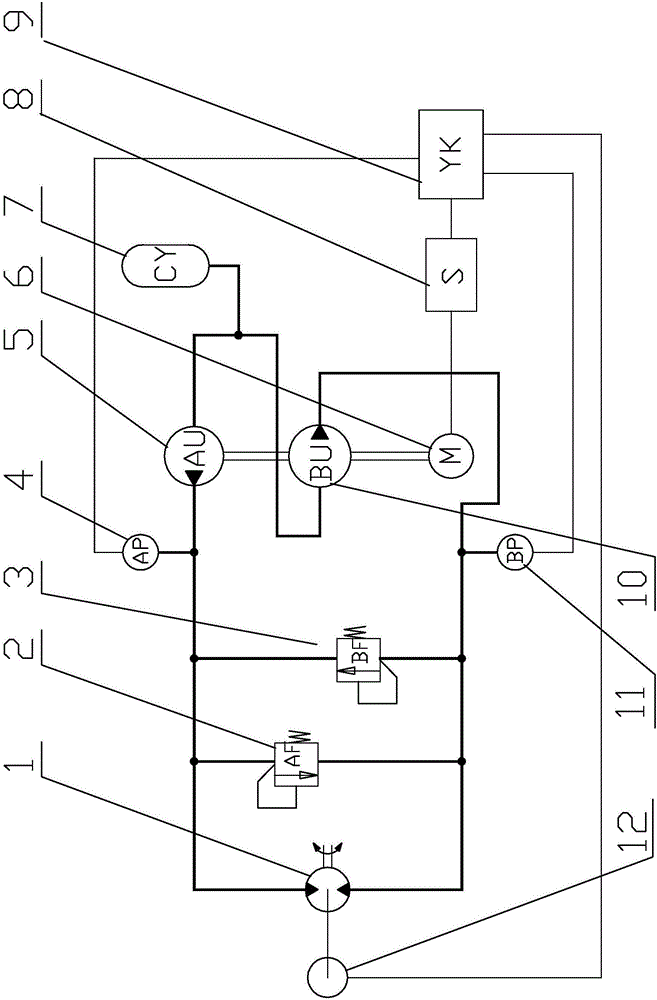

[0038] In this embodiment 2 such as figure 2 As shown, the A hydraulic pump 5 is a forward pump, and the B hydraulic pump 10 is a reverse pump, which are installed on the front axle of the servo motor 6 together. A liquid storage / accumulator 7 is also connected to the oil circuit connecting the A hydraulic pump 5 and the B hydraulic pump 10 , and the other structures of the second embodiment are the same as those of the first embodiment.

Embodiment 3

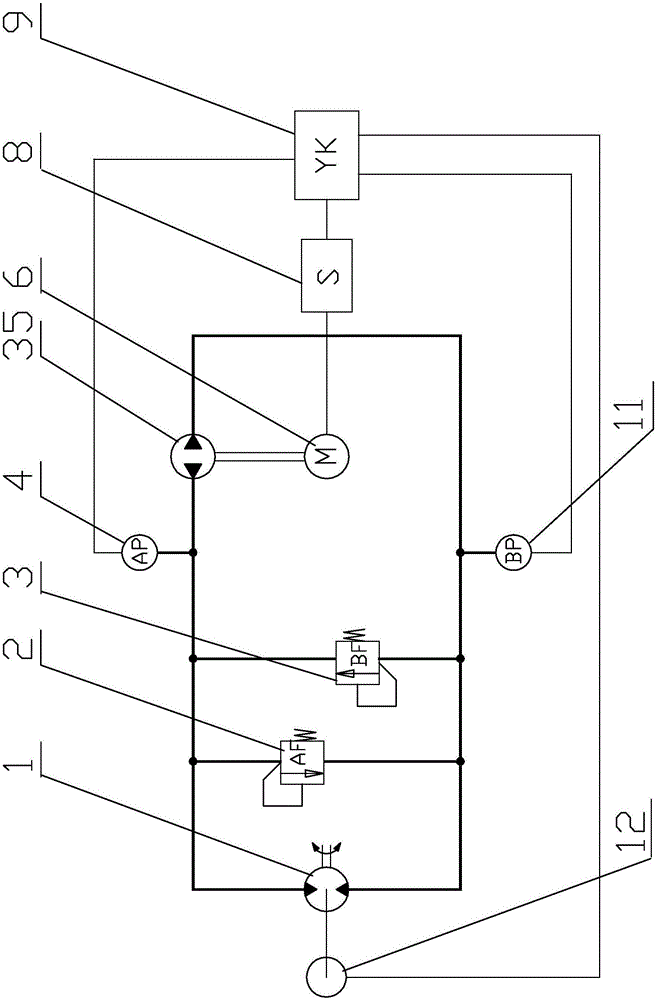

[0040] The present embodiment 3 such as image 3 As shown, the two-way pump 35 (DU shown in the figure) replaces the A hydraulic pump 5 and the B hydraulic pump 10 in the embodiment 1. The two-way pump 35 has an A oil outlet and a B oil outlet, respectively connected to the hydraulic pressure Forward oil inlet and reverse oil inlet of motor 1. When the servo motor 6 rotates forward, A of the two-way pump 35 outputs hydraulic oil to the oil outlet and B sucks hydraulic oil to the oil outlet. When the servo motor 6 reverses, B outputs hydraulic oil to the oil outlet while A The oil port sucks hydraulic oil. In this example, an oil supply valve or an oil supply port is installed on the oil circuit where the A-direction oil outlet and the B-direction oil outlet of the bidirectional pump 35 are connected to each other. When the oil leaks in the oil circuit, the oil supply valve or the oil supply port replenishes the oil circuit Hydraulic oil. Other structures of the third embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com