High-sensitivity fiber Bragg grating strain sensor based on flexible hinges

A strain sensor and flexible hinge technology, which is used in the high-precision measurement of strain in various mechanical structures, and in the field of high-sensitivity fiber grating strain sensors. Small, compact structure, good long-term reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing.

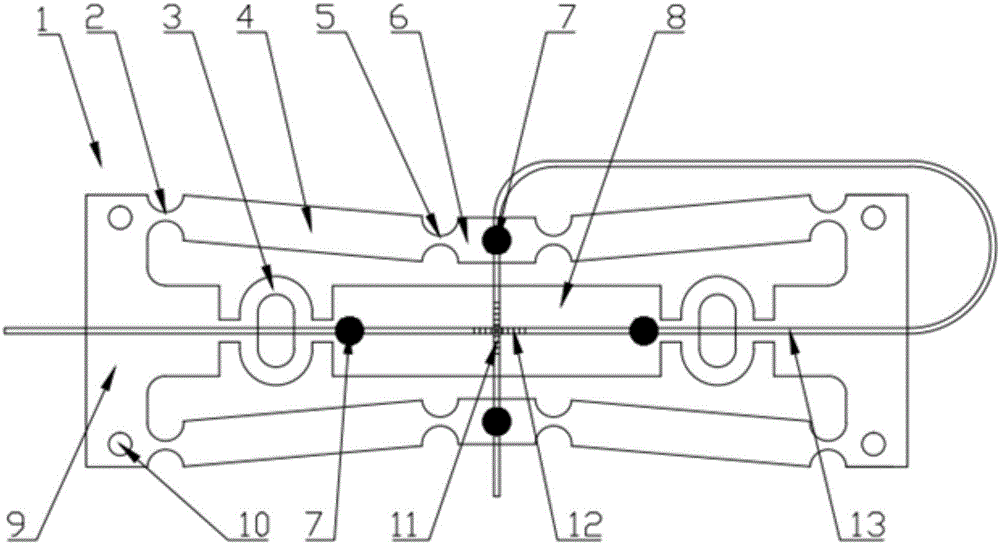

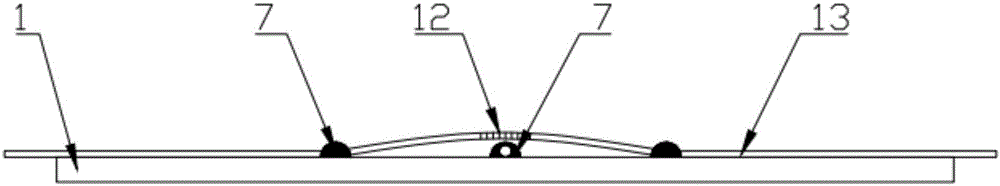

[0027] Such as figure 1 , 2 As shown, the present embodiment provides a high-sensitivity fiber grating strain sensor based on a flexible hinge, including an elastic strain substrate 1 and a fiber grating string 13, and the two ends of the strain measurement grating 11 and the temperature compensation grating 12 on the fiber grating string 13 It is fixed at the corresponding position on the elastic strain substrate 1 .

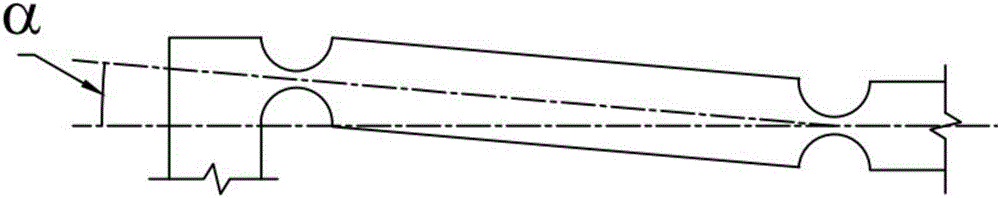

[0028] The elastic strain substrate 1 has a longitudinal axis and a transverse axis, and is arranged symmetrically along the longitudinal axis and the transverse axis respectively, and includes a beam 8, an O-shaped elastic strain unit 3, a fixed end 9, and a displacement amplification mechanism. The ends are respectively connected to the fixed end 9 through the elastic strain unit 3 to form a temperature compensation mechanism. The displacement amplifying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com