Multidimensional rod structure array pressure sensor and integration method thereof

A pressure sensor and sensor technology, which is applied in the direction of fluid pressure measurement using piezoelectric devices and the measurement of the property force of piezoelectric devices, can solve the problem of reducing the interlayer bonding force of composite materials and affecting the interlayer bonding strength of composite materials, etc. problem, to achieve the effect of good use and service

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

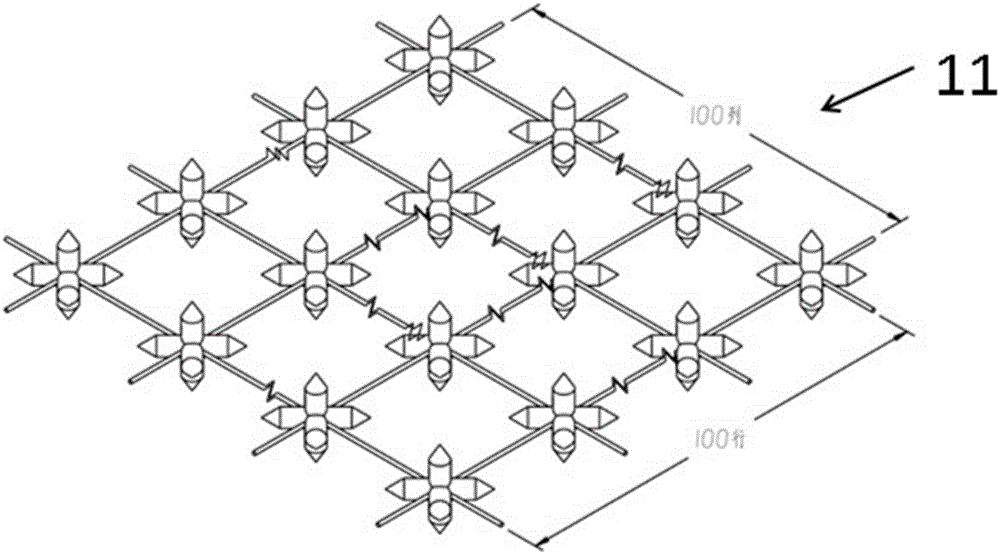

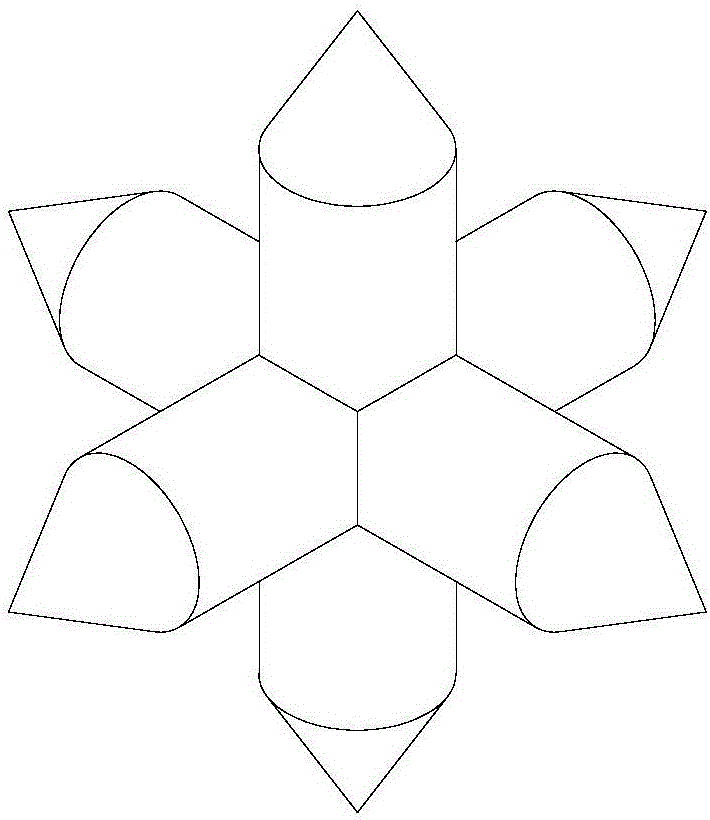

[0024] An array pressure sensor with a multi-dimensional rod structure described in this embodiment is applied to a composite material wing structure, and the wall thickness of the composite material is 12 mm. The multidimensional rod array sensor 11 is composed of a multidimensional rod sensor 112 and a wire 111 forming a 10x32 array; for the multidimensional rod sensor 112, see figure 2 , its length is 3mm, including 8 rods, the rods are arranged in a rectangular coordinate shape in space, and 8 wires are drawn from a single multidimensional rod sensor 112 to connect with the wire 111; the material of the single rod is PVDF piezoelectric material, and its diameter is 1.5mm, tension, compression or combined tension and compression loads will generate a signal. The wires connect a single multi-dimensional bar sensor into an 8x30 two-dimensional array sensor, see Figure 7 .

[0025] The integration method of the first embodiment

[0026] The shape of the array sensor descr...

Embodiment 2

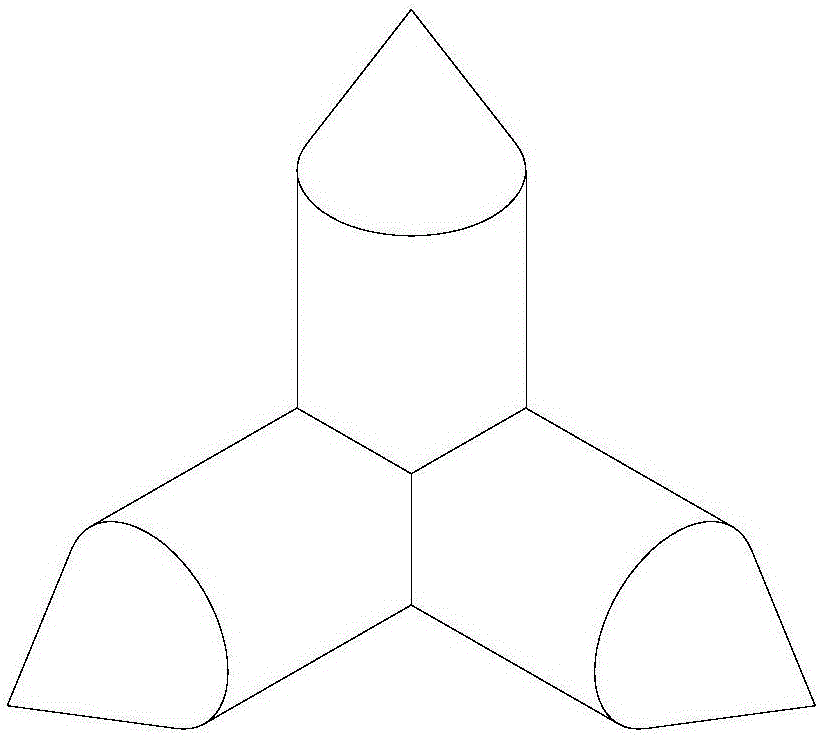

[0028] An array pressure sensor with a multi-dimensional rod structure described in this embodiment is applied to a fuselage structure made of composite material, and the wall thickness of the composite material is 15 mm. The array sensor 11 is composed of a plurality of multidimensional rod sensors 112 arranged in an array, and its height is 3mm. This multidimensional rod sensor includes 3 rods, and the rods are arranged in a spatial rectangular coordinate shape. Figure 4 , 3 wires 111 are connected to a single multi-dimensional rod sensor. The material of the single rod is piezoelectric material with a diameter of 1.5 mm. It will generate signals under tension, compression or combined tension and compression loads. The wires connect single multi-dimensional rod sensors into a barrel-shaped array sensor. There are 9 barrel arrays arranged in the circumferential direction, and 10 layers arranged in the longitudinal direction, see Figure 8 ;During the laying process of the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com