Automatic pressure tapping device

An automatic and differential pressure technology, applied in the field of automatic pressure taking devices, can solve the problems of complicated pressure taking pipelines, complicated operations, inaccurate water pump simulation, etc., and achieve the effect of reducing the number of pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

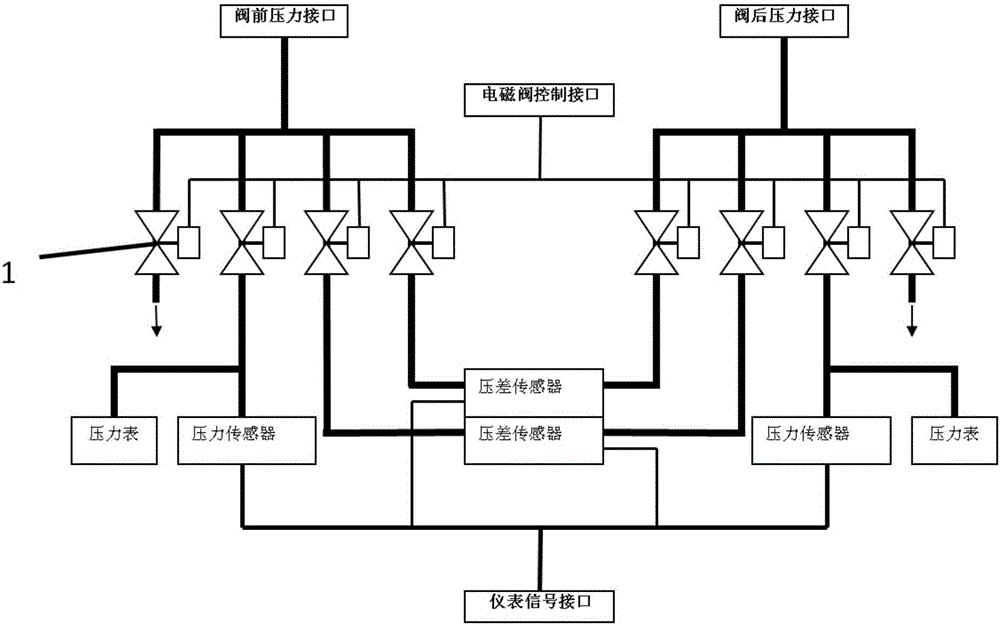

[0019] like figure 1 As shown, a pressure taking system in an automatic pressure taking device, the pressure taking system includes a pressure taking pipeline, a measuring instrument, a solenoid valve control interface, a solenoid valve group and an instrument signal interface, and the pressure taking pipeline and the solenoid valve control interface are respectively The input end of the electromagnetic valve group is connected, the output end of the electromagnetic valve group is connected to the measuring instrument, and the measuring instrument is connected to the instrument signal interface.

[0020] like figure 1 As shown, the pressure detection pipeline includes the pressure port before the valve and the pressure port after the valve. The pressure detection pipeline to be connected is designed as a set of pipeline system according to the requirements of use, and only the connection operation between the pressure port before the valve and the pressure port after the valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com