A Comprehensive Management System for Oil Production Well Equipment

A technology of equipment integration and management system, which is applied in the field of oil production well equipment integrated management system, can solve problems such as inability to model, error-prone, complex wiring, etc., and achieve real-time data and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

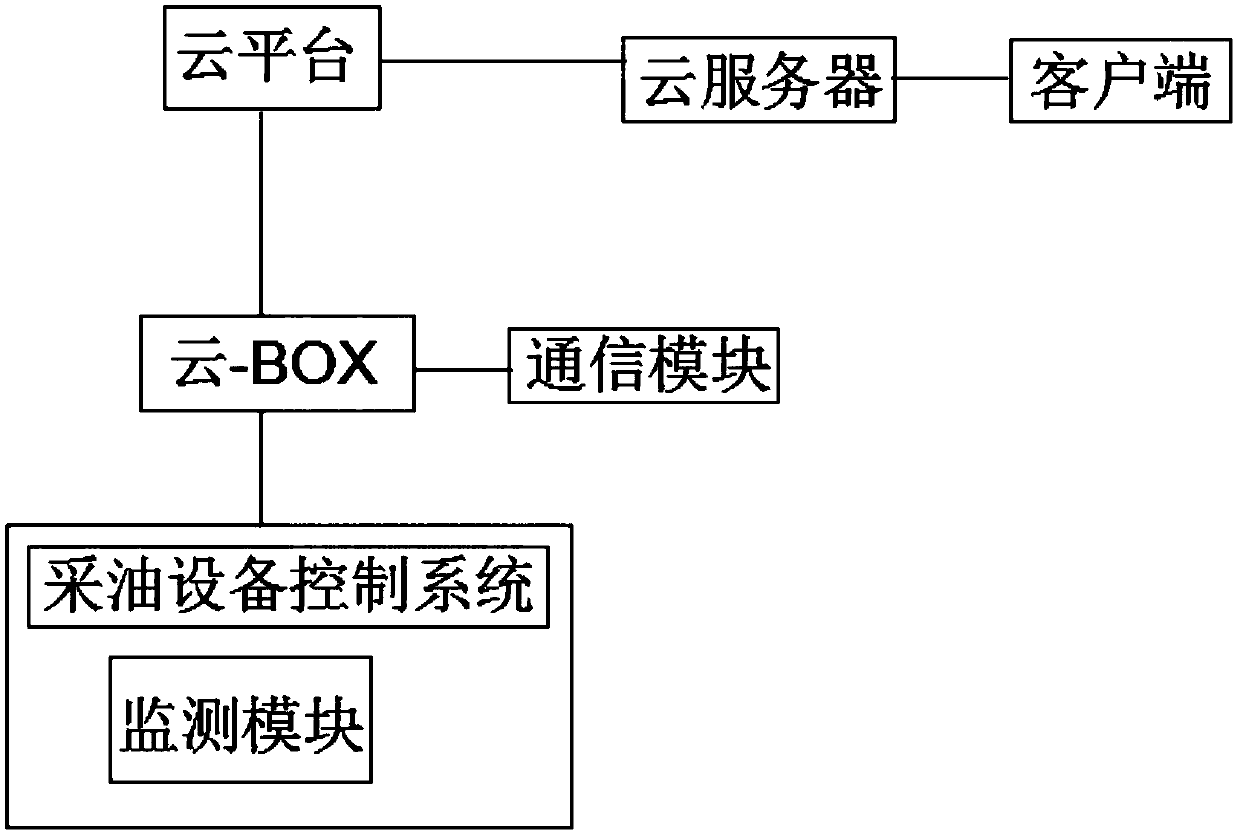

[0024] see figure 1 , an integrated management system for oil production well equipment, including cloud server, cloud-BOX, oil production equipment control system and monitoring module; the monitoring module is used to collect real-time relevant data of oil production equipment operating The data collected by the detection equipment is transmitted to the cloud platform, and the cloud platform is used to receive and store the relevant data collected by the monitoring device; the cloud platform collects the main parameters of the oil production equipment through the cloud server and cloud-box, and automatically analyzes the big data Synchronization is convenient for users to access the cloud platform through communication devices such as mobile phones and PCs, and to query the operation status and usage effects of the system in real time....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com