IGBT device and manufacturing method thereof

A device and substrate technology, applied in the field of IGBT devices and their fabrication, can solve problems such as burnout and breakdown of IGBT devices, and achieve the effects of reducing the rate of change, increasing the Miller capacitance, and improving the ability to resist latch-up.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

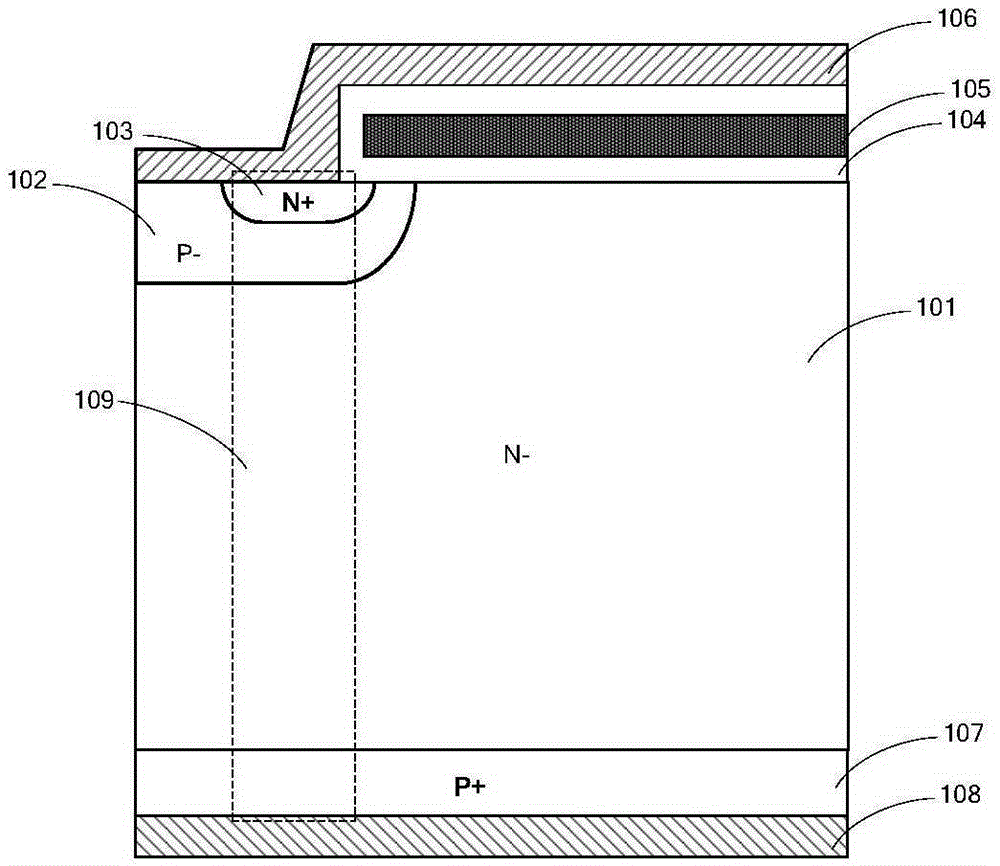

[0032] As mentioned in the background technology, there will inevitably be parasitic thyristors in the structure of the IGBT device, so that the voltage borne by the IGBT device will rise and fall rapidly in a short period of time during the turn-on and turn-off process, even if the voltage has a high change Rate. When the rate of change of the voltage is large enough, the parasitic thyristor may be triggered, so that the IGBT device is no longer controlled by the gate, causing a latch-up effect, which in turn leads to problems such as breakdown and burnout of the IGBT device.

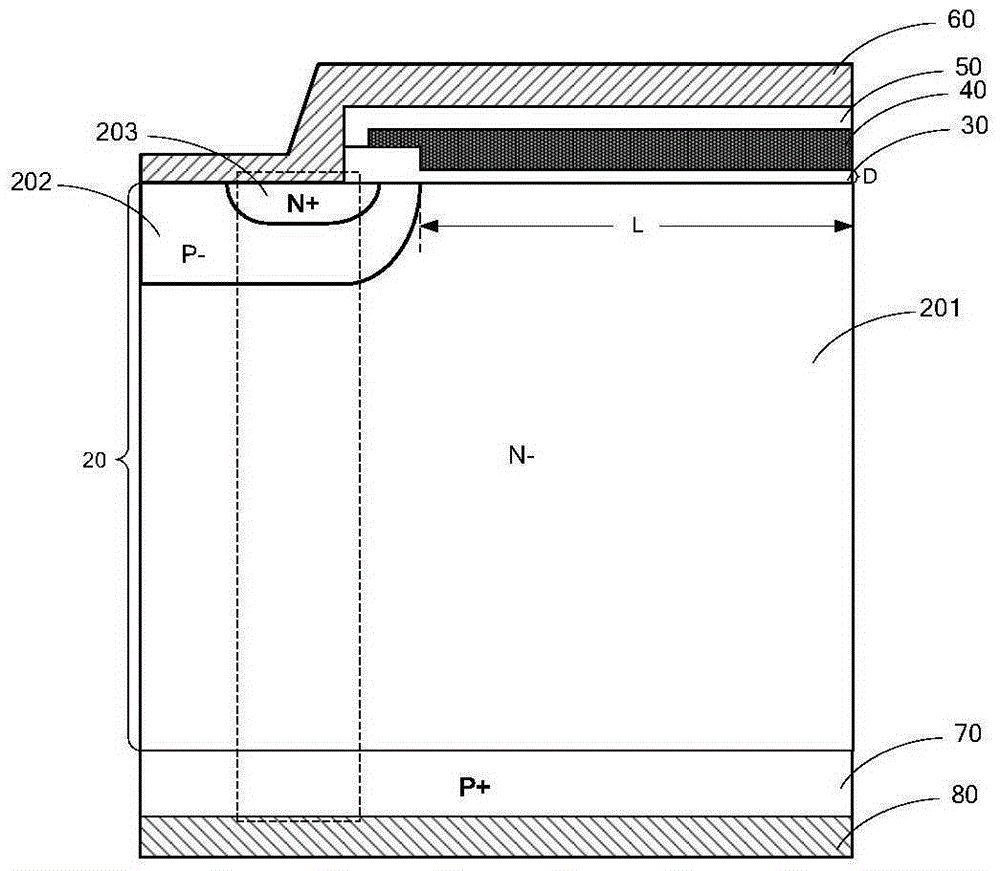

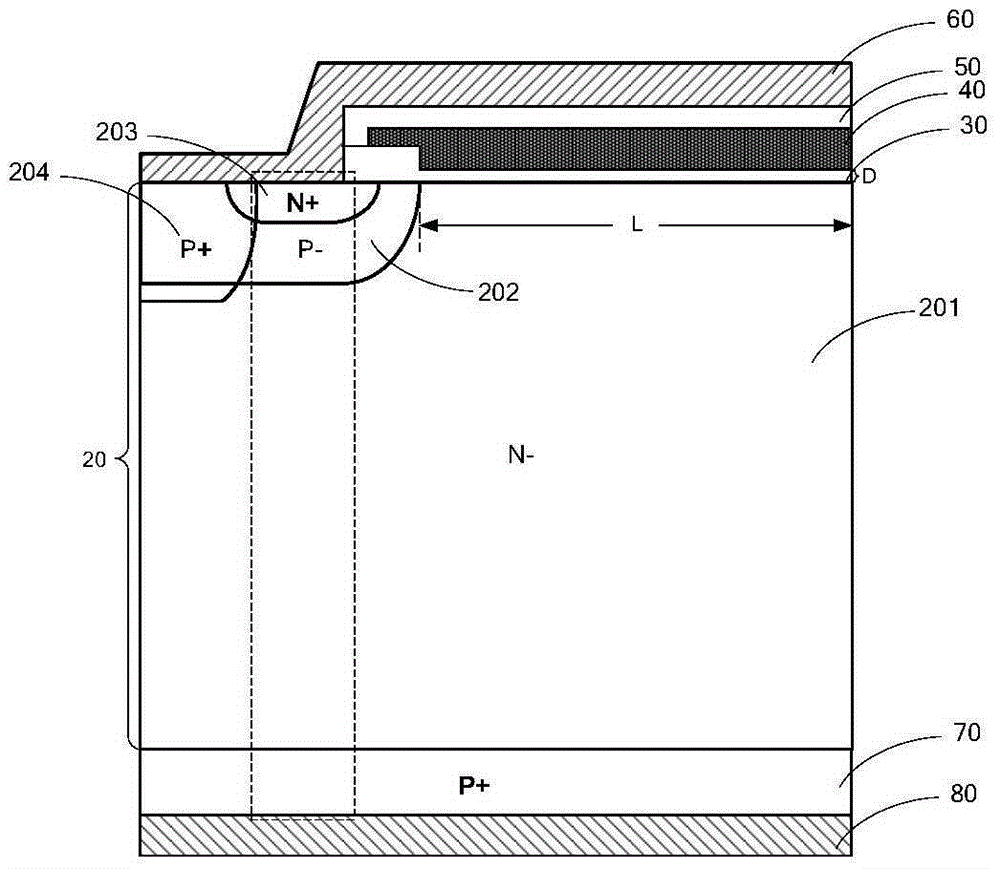

[0033] Based on this, the present invention provides an IGBT device and a manufacturing method thereof to overcome the above-mentioned problems in the prior art, including:

[0034] A substrate, the substrate includes a body layer, a well region and a source region located in the surface of the body layer; a first dielectric layer located on the front side of the substrate and a gate located on the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com