High stability white light LED packaging method and high stability white light LED packaging structure

A technology of LED packaging and high stability, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., and can solve problems such as drift, large heat generation of LED chips, and attenuation of color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

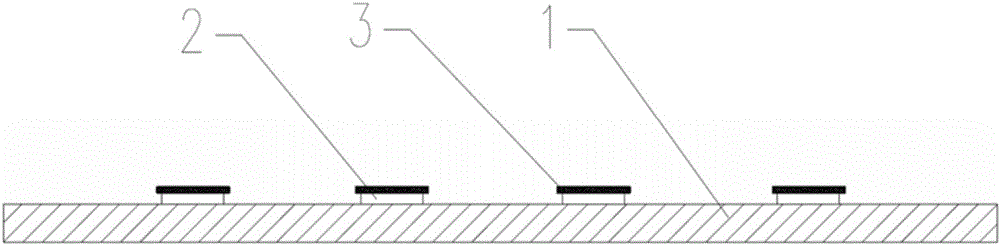

[0032] Such as figure 1 As shown, it is a high-stability white LED packaging structure according to the present invention, which includes an LED chip 2 fixed on a substrate 1 and a light conversion medium 3 covering the light-emitting surface of the LED chip 2, and the light emitted by the LED chip 2 After passing through the light conversion medium 3, the light is converted to obtain highly stable white light. Further, the optimal wavelength of light emitted by the LED chip is between 420-470nm. The LED chip adopts a flip chip or a vertical chip; the LED chip is connected in series, parallel or series-parallel; the LED chip is fixed on the substrate by flip chip, front mounting or eutectic welding, and the material of the substrate is Any of ALN (aluminum nitride), aluminum oxide, a copper substrate, or an aluminum substrate may be used.

[0033] The light conversion medium is any one of glass, transparent ceramics, and single crystals; the light conversion medium described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com