Coplanar waveguide feeding-based semi-ring-shaped surface wave transmission line and power splitter

A coplanar waveguide and semi-circular technology, which is applied in the direction of waveguide devices, circuits, electrical components, etc., can solve the problems of inability to integrate surface waves and microstrip circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

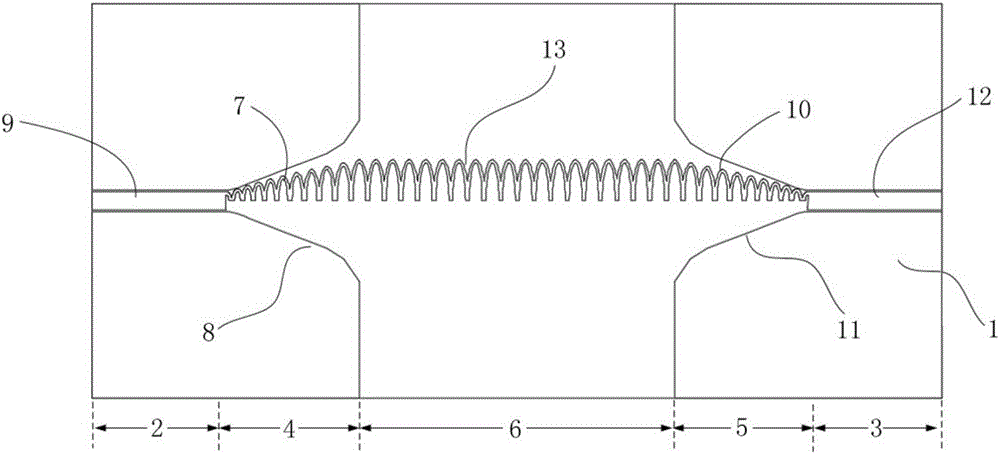

[0041] Such as figure 1 As shown, the surface wave transmission line of this embodiment includes a dielectric substrate 1, a first coplanar waveguide 2, a second coplanar waveguide 3, a first transition structure 4, a second transition structure 5 and a semi-annular surface wave structure 6. The first coplanar waveguide 2, the second coplanar waveguide 3, the first transition structure 4, the second transition structure 5 and the semi-annular surface wave structure 6 are arranged on the same layer of the dielectric substrate 1, and in this embodiment are arranged on the top layer , the bottom layer of the dielectric substrate 1 has no copper clad ground; the first coplanar waveguide 2 and the second coplanar waveguide 3 are left-right symmetrical, and the first transition structure 4 and the second transition structure 5 are left-right symmetrical.

[0042] The first transition structure 4 includes a plurality of first semi-annular transition units 7 and first metal units 8 lo...

Embodiment 2

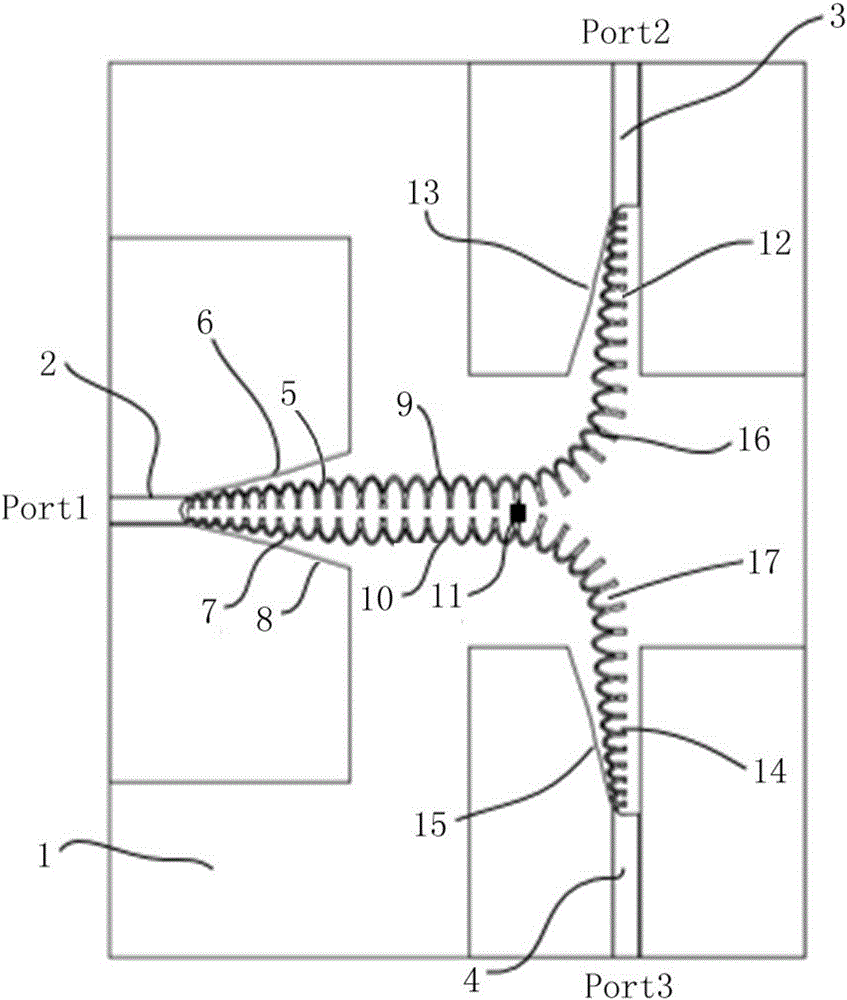

[0046] Such as figure 2 As shown, the surface wave power splitter of this embodiment includes a dielectric substrate 1, a first coplanar waveguide 2, a second coplanar waveguide 3, a third coplanar waveguide 4, a first transition structure, a second transition structure, a third The transition structure, the fourth transition structure, the first semi-annular surface wave structure, the second semi-annular surface wave structure, the third semi-annular surface wave structure and the fourth semi-annular surface wave structure, the first coplanar waveguide 2, the second Two coplanar waveguides 3, third coplanar waveguides 4, first transition structure, second transition structure, third transition structure, fourth transition structure, first semi-annular surface wave structure, second semi-annular surface wave structure, and second semi-annular surface wave structure The three-half annular surface wave structure and the fourth half-annular surface wave structure are arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com